Semiconductor manufacturing has always been a vital component of technological advancements. The modern world is increasingly reliant on electronics, and at the heart of every electronic device is a semiconductor. Over the years, semiconductor manufacturing equipment has undergone massive changes to meet the growing complexity and scale of chip production. This article explores the latest trends and innovations shaping the semiconductor manufacturing equipment industry today.

Historical Evolution of Semiconductor Manufacturing

Early Developments

The semiconductor industry began in the mid-20th century when transistors first replaced vacuum tubes. Early semiconductor manufacturing was labor-intensive, with simple equipment used for tasks like diffusion and etching. As demand for faster, smaller, and more efficient chips grew, so did the need for more advanced manufacturing tools.

Key Milestones in Equipment Advancements

In the 1970s and 1980s, breakthroughs such as photolithography and chemical vapor deposition (CVD) laid the foundation for modern chip production. Equipment manufacturers like ASML and Applied Materials played pivotal roles in revolutionizing semiconductor fabrication by creating precision machines capable of producing millions of transistors on a single chip.

Types of Semiconductor Manufacturing Equipment

Lithography Equipment

Lithography is the process of transferring a pattern onto a semiconductor wafer. Extreme ultraviolet (EUV) lithography represents the latest advancement in this field, allowing manufacturers to etch features as small as 7 nm onto silicon wafers.

Deposition Equipment

Chemical vapor deposition (CVD) and atomic layer deposition (ALD) are commonly used to deposit thin films of material onto wafers. ALD, in particular, has gained prominence due to its precision in depositing materials layer by layer.

Etching Equipment

Etching equipment removes layers from the wafer’s surface to create intricate circuits. Dry etching, such as reactive ion etching (RIE), allows for the removal of specific areas with great precision, enhancing the complexity of chip designs.

Wafer Inspection and Metrology Tools

These tools are critical for quality control. They ensure that each wafer meets the design specifications and that defects are detected early in the manufacturing process.

Market Growth Projections for Semiconductor Manufacturing Equipment

The semiconductor manufacturing equipment market is expected to grow significantly, reaching USD 155.09 billion by 2029, up from USD 109.24 billion in 2024. This growth represents a compound annual growth rate (CAGR) of 7.3% during the forecast period. Several key factors are fueling this expansion, including advancements in packaging technologies, increased government support for domestic semiconductor industries, and the ongoing development of semiconductor fabrication facilities worldwide.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=263678841

Current Market Trends in Semiconductor Equipment

Increased Demand for Advanced Chips

As technologies like AI, 5G, and the Internet of Things (IoT) become more prevalent, the demand for advanced semiconductor chips has skyrocketed. This has pushed equipment manufacturers to innovate rapidly.

Expansion of Foundry Capacity

To meet the global chip shortage, foundries (companies that produce semiconductors) are investing heavily in expanding their manufacturing capacities. This, in turn, drives demand for semiconductor manufacturing equipment.

Growth of Fabless Semiconductor Companies

Fabless companies like Qualcomm and NVIDIA design chips but outsource manufacturing to foundries. This trend has led to a surge in partnerships between equipment manufacturers and semiconductor foundries.

Key Innovations in Semiconductor Manufacturing Equipment

Extreme Ultraviolet Lithography (EUV)

EUV lithography is a revolutionary technology that allows for the creation of extremely small and precise patterns on semiconductor wafers. This innovation is critical in enabling the production of advanced chips for applications like 5G and AI.

EUV lithography is a revolutionary technology that allows for the creation of extremely small and precise patterns on semiconductor wafers. This innovation is critical in enabling the production of advanced chips for applications like 5G and AI.

3D ICs and Advanced Packaging Techniques

3D integrated circuits (ICs) stack multiple layers of chips, increasing performance and reducing power consumption. Advanced packaging techniques, such as fan-out wafer-level packaging (FO-WLP), enhance the performance of semiconductor devices.

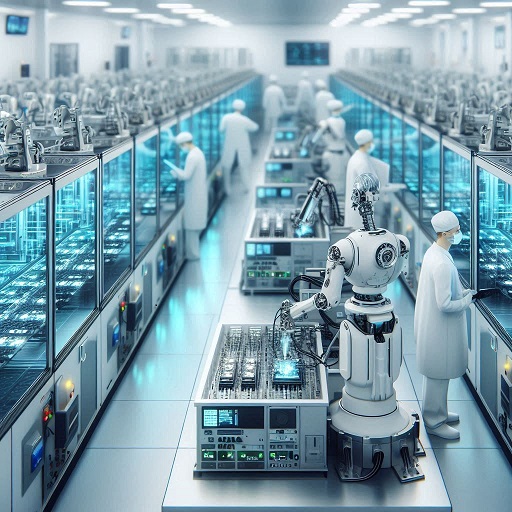

Impact of Automation and AI on Semiconductor Manufacturing

Role of AI in Equipment Maintenance

AI-driven predictive maintenance helps identify potential issues in equipment before they cause disruptions, improving the overall efficiency of semiconductor fabs.

Automation in Wafer Handling

Automation plays a critical role in handling wafers in cleanroom environments, reducing human error and contamination risks.

Predictive Analytics for Yield Optimization

Predictive analytics helps manufacturers optimize yields by analyzing data from previous production cycles and predicting which factors could cause defects.

Challenges in Semiconductor Manufacturing

Equipment Costs

One of the most significant challenges faced by the semiconductor manufacturing industry is the high cost of advanced manufacturing equipment. The development and production of cutting-edge tools, such as EUV lithography systems, require substantial investments. These costs can hinder smaller companies from entering the market or expanding their operations, leading to a concentration of power among a few dominant players.

Technological Complexity

As semiconductor technology advances, so does the complexity of the manufacturing equipment. With the continuous push towards smaller and more powerful chips, equipment manufacturers must innovate rapidly to keep up with the demands of the market. This complexity can lead to longer development times and increased risk of technical failures during production.

Supply Chain Constraints

The semiconductor industry has been particularly vulnerable to supply chain disruptions, as witnessed during the COVID-19 pandemic. Equipment manufacturers depend on a vast network of suppliers for components and raw materials. Disruptions in this supply chain can delay production timelines and increase costs, further complicating the already intricate manufacturing process.

Regional Insights: Key Players in Semiconductor Equipment Market

North America

North America has long been a leader in semiconductor manufacturing and equipment production. Companies such as Applied Materials and Lam Research are headquartered in the region, driving innovation and technological advancements. The presence of leading research institutions and universities also fosters collaboration and development within the industry.

Asia-Pacific

The Asia-Pacific region is home to some of the largest semiconductor manufacturing companies in the world, including TSMC and Samsung. These companies are investing heavily in expanding their production capabilities and advancing their manufacturing technologies. As demand for chips continues to rise, the Asia-Pacific region is likely to play an increasingly critical role in the global semiconductor supply chain.

Europe

Europe is also making strides in semiconductor manufacturing, with initiatives aimed at increasing local production capabilities. Companies like ASML and global collaboration efforts, such as the European Chips Act, aim to enhance Europe’s position in the semiconductor landscape. This focus on local production is driven by the desire for greater self-sufficiency and reduced reliance on external suppliers.

In summary, the semiconductor manufacturing equipment industry is undergoing significant changes driven by technological advancements, market demands, and environmental considerations. Innovations such as EUV lithography, automation, and new materials are shaping the future of semiconductor production.

Looking ahead, the semiconductor manufacturing industry will continue to evolve, presenting both challenges and opportunities for equipment manufacturers. As the demand for advanced chips grows, the focus on sustainability and innovation will play a crucial role in shaping the industry’s future.

FAQs:

- What is the role of lithography in semiconductor manufacturing? Lithography is a key process in semiconductor manufacturing that involves transferring patterns onto silicon wafers to create circuits.

- What are the latest innovations in semiconductor manufacturing equipment? Some of the latest innovations include EUV lithography, atomic layer deposition, and advanced packaging techniques like 3D ICs.

- Why is automation important in semiconductor manufacturing? Automation reduces human error, improves precision, and enhances overall production efficiency in semiconductor fabs.

- What challenges does the semiconductor equipment industry face? Challenges include high equipment costs, complex technologies, and supply chain constraints.

- How does semiconductor manufacturing impact the environment? Manufacturers are focusing on reducing energy consumption, water usage, and waste generation to minimize the environmental impact.

- What regions are leading the semiconductor equipment market? North America, Asia-Pacific, and Europe are key players in the semiconductor equipment market.