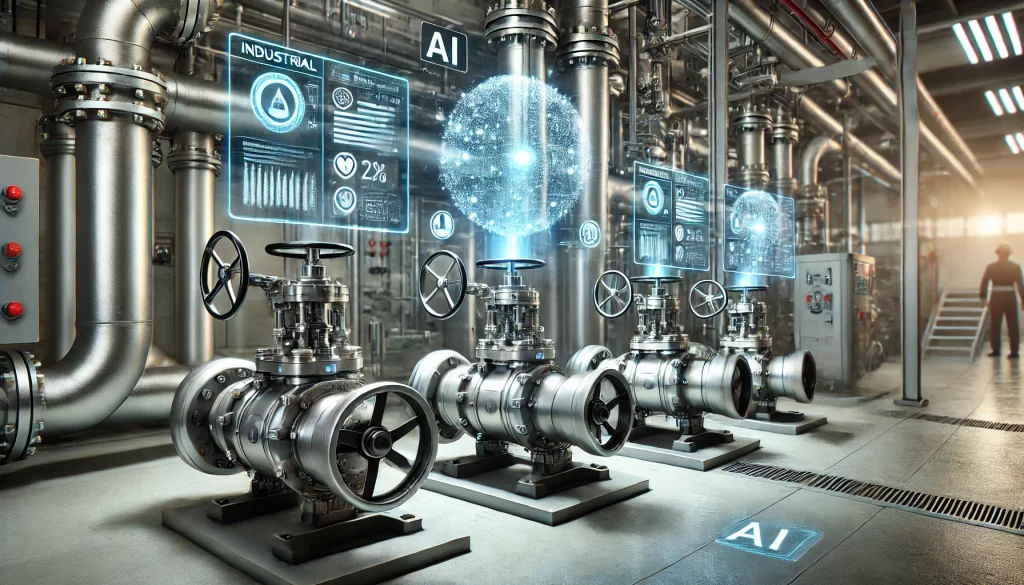

As industries worldwide embrace digital transformation, artificial intelligence (AI) is emerging as a cornerstone in driving efficiency, reliability, and adaptability. A significant example of this transformation is the integration of AI into industrial valves, which play a critical role in controlling the flow of fluids and gases in various sectors, including oil and gas, chemical, pharmaceuticals, and water treatment. AI-powered industrial valves are ushering in an era of smart automation, predictive maintenance, and enhanced safety, all of which are critical for modern industrial operations.

The industrial valves market ecosystem involves manufacturers and end-users across various sectors such as oil & gas, water treatment, pharmaceutical, and food & beverage. Manufacturers focus on innovation and advanced materials to improve valve performance and efficiency. End-users drive demand for automation and sustainability. Regulatory bodies set safety standards, influencing industry dynamics and fostering advancements in flow control solutions. Key companies include Emerson Electric Co. (US), SLB (US), Flowserve Corporation (US), IMI (UK), and Crane Company (US).

Impact of AI on Industrial Valves Market

AI helps choose the best valve and characteristics for each application by accessing the expert systems trained by industry experts such as subcontractors, manufacturers, contractors, and users. With a wide range of data and industry knowledge, AI ensures customers get the best recommendations tailored to their needs, operating conditions, and performance requirements. Deviations from the standard recommendation would be well supported by data that, in turn, would enhance decision-making and help prevent errors; this advanced approach maximizes valve performance, efficiency, and longevity in most industries.

Impact of AI on Industrial Valves Market

AI helps choose the best valve and characteristics for each application by accessing the expert systems trained by industry experts such as subcontractors, manufacturers, contractors, and users. With a wide range of data and industry knowledge, AI ensures customers get the best recommendations tailored to their needs, operating conditions, and performance requirements. Deviations from the standard recommendation would be well supported by data that, in turn, would enhance decision-making and help prevent errors; this advanced approach maximizes valve performance, efficiency, and longevity in most industries.

What Are AI Industrial Valves?

Traditional industrial valves are mechanical devices used to regulate, direct, or control the flow of liquids and gases by opening, closing, or partially obstructing passageways. AI industrial valves, however, go beyond simple mechanical function by incorporating advanced algorithms, sensors, and connectivity features to create an intelligent system that can respond autonomously and in real-time. These valves can analyze data, communicate with other devices, and optimize performance based on environmental and operational conditions.

Key Benefits of AI-Enhanced Industrial Valves

- Predictive Maintenance

One of the most valuable benefits of AI-enabled valves is predictive maintenance. Traditional valves often suffer from wear and tear, corrosion, and unexpected breakdowns. AI-enhanced valves can monitor their own health through real-time data analysis, identifying early signs of degradation, leakage, or potential failures. By predicting and scheduling maintenance before issues arise, companies can reduce downtime and improve efficiency. - Enhanced Process Automation and Efficiency

AI valves enable advanced process automation by continuously monitoring fluid properties (like pressure, temperature, and flow rate) and autonomously adjusting valve settings to maintain optimal performance. This self-regulation minimizes the need for human intervention and ensures consistent, efficient operations, even under varying conditions. - Data-Driven Decision-Making

Equipped with sensors and connectivity, AI valves can collect, analyze, and share data with other industrial systems. This data-driven approach allows plant operators to make informed decisions based on real-time insights. For instance, data from AI valves can inform optimization of production processes, energy consumption reduction, and resource allocation, leading to overall operational excellence. - Energy Efficiency and Sustainability

AI-powered valves can optimize fluid flow with precise control, resulting in reduced energy consumption. This energy efficiency not only lowers operational costs but also supports sustainability goals by minimizing the carbon footprint associated with industrial processes. - Enhanced Safety and Risk Mitigation

Industrial environments often carry inherent risks due to high pressures, temperatures, and hazardous materials. AI-enabled valves can detect abnormalities like pressure spikes, flow interruptions, or leaks. They can initiate automatic shutdowns or trigger alarms, helping to prevent accidents and improve safety for personnel and equipment alike.

Key Technologies Enabling AI in Industrial Valves

- Machine Learning (ML) Algorithms

Machine learning algorithms help analyze patterns in operational data, which AI-enabled valves use to predict equipment failure, optimize performance, and respond to anomalies. - Internet of Things (IoT)

IoT sensors are integral to AI industrial valves, enabling real-time data collection, sharing, and cloud-based analytics. These sensors allow valves to communicate with other devices and systems, creating a connected ecosystem for industrial process automation. - Edge Computing

Edge computing allows data processing to occur near the valve itself, reducing the latency of decision-making and enabling faster, more reliable responses to changing conditions without relying solely on cloud infrastructure.

Applications of AI Industrial Valves Across Industries

- Oil and Gas

In oil and gas, where valve failure can lead to significant financial losses and environmental harm, AI valves help optimize production rates, maintain safety standards, and reduce unplanned shutdowns. - Water and Wastewater Treatment

AI valves help control the distribution and treatment processes with minimal human intervention, providing efficient resource allocation and reducing waste. - Chemical and Pharmaceuticals

AI industrial valves maintain precision in chemical processes, critical in these industries for ensuring product quality and compliance with stringent safety regulations. - Power Generation

By using AI valves to manage steam flows and cooling systems, power plants can enhance energy efficiency, reduce emissions, and ensure uninterrupted energy supply.

Challenges and Considerations in Implementing AI Industrial Valves

While AI industrial valves offer transformative benefits, implementation requires addressing certain challenges. These include the high initial cost of AI-enabled valves, integration with legacy systems, and the need for cybersecurity measures to protect against data breaches. Additionally, industrial staff must be trained to work with AI systems to maximize their potential and ensure smooth transitions.

Future Outlook for AI in Industrial Valves

As AI technology advances, the capabilities of industrial valves will continue to expand. Future valves may include more sophisticated predictive analytics, advanced anomaly detection, and further integration with digital twins, enabling industries to simulate valve performance and environmental impacts in virtual environments before applying them in real-world conditions. AI-powered valves will become more adaptive, intelligent, and autonomous, helping industries meet evolving operational, environmental, and economic demands.

AI industrial valves represent a pivotal shift in process automation, maintenance, and safety across numerous industries. By combining mechanical reliability with digital intelligence, these valves offer unmatched efficiency and safety advantages, providing industries with the tools they need to meet 21st-century challenges. As AI technology continues to evolve, so will the capabilities and applications of these intelligent systems, paving the way for smarter, safer, and more sustainable industrial practices.