The semiconductor industry is at the heart of technological innovation, powering everything from smartphones to autonomous vehicles. As demand for more powerful, efficient, and compact devices grows, the need for advanced semiconductor manufacturing processes has never been greater. One of the most cutting-edge techniques in semiconductor production today is Extreme Ultraviolet (EUV) lithography, a process that uses short-wavelength light to create intricate patterns on silicon wafers. However, with the increasing complexity of modern chip designs and the push toward ever-smaller nodes, EUV lithography has encountered challenges that require innovative solutions. Enter Artificial Intelligence (AI), which is proving to be a game-changer in overcoming these hurdles, revolutionizing how chips are made, and pushing the boundaries of semiconductor technology.

The shift towards data-driven technologies, artificial intelligence (Al) and high-performance computing (HPC) applications is creating demand for more sophisticated and capable semiconductors. With data analytics, Al, and machine learning progressively being used within enterprises to improve decision-making and operational efficiency, the demand for high-density, high-performance integrated circuits (ICs) are at an all-time high. Fundamentally, EUV lithography is at the heart of this demand, which needs to produce the semiconductor that brings the computational power and energy efficiency that is required.

The EUV lithography market size is expected to reach USD 22.69 billion by 2029 from USD 12.18 billion in 2024, at a CAGR of 13.2% during the 2024-2029 period.

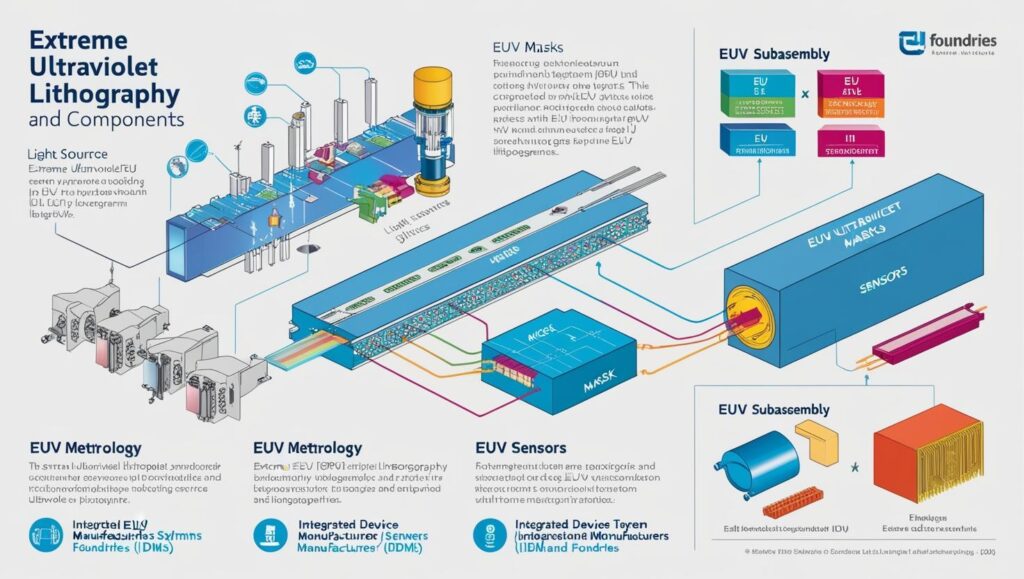

Extreme Ultraviolet (EUV) lithography is a photolithographic technique used to manufacture integrated circuits at advanced nodes, typically below 7nm. The key to EUV’s success is its ability to utilize light with a wavelength of just 13.5 nanometers, which allows it to pattern smaller and more precise features on silicon wafers compared to traditional photolithography. This capability is essential for the production of next-generation semiconductors, which are becoming increasingly smaller and more powerful, with transistors continuing to shrink in size.

While EUV lithography represents a significant leap forward in semiconductor fabrication, it is an extremely complex process that involves precise control of numerous variables, including light exposure, resist material, and wafer alignment. The precision required for EUV to work at its full potential often presents challenges in both the manufacturing and design stages of chip production.

AI’s Role in Advancing EUV Lithography

AI technologies, particularly machine learning (ML) and deep learning, have emerged as critical tools for enhancing EUV lithography. AI can address the challenges faced by chipmakers, helping to optimize processes and improve yield rates. By leveraging vast amounts of data, AI can predict, analyze, and control variables that would otherwise be too complex for traditional methods.

Here are some key ways AI is transforming the EUV lithography landscape:

1. Optimizing Mask Design and Patterning

In EUV lithography, masks are used to project circuit patterns onto the wafer. The design of these masks is critical, as even the slightest imperfections can lead to defects and lower yields. AI algorithms can optimize mask design by simulating how the mask will interact with the EUV light, identifying potential issues in the patterning process before they occur. This reduces the need for trial and error and enables faster design iterations.

Additionally, AI can predict how the mask’s patterning will respond to different exposure levels, optimizing light distribution and helping to minimize defects that could degrade the chip’s performance.

2. Enhancing Process Control and Metrology

EUV lithography requires incredibly precise control over the process, with extremely small margins of error. AI-driven systems are being used to improve metrology (the science of measurement) and process control during wafer fabrication. By continuously monitoring parameters such as focus, exposure dose, and temperature, AI can predict potential issues in real-time and adjust the process accordingly. This dynamic adjustment reduces the risk of defects and increases overall production efficiency.

AI is also being used to analyze metrology data to identify correlations that are difficult for humans to detect, allowing for more accurate predictions about how variations in the process will affect the final product.

Download PDF Brochure @

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=241564826

3. Predicting and Preventing Defects

As chip designs become more complex and nodes shrink, the likelihood of defects increases. These defects can cause yield loss and inefficiencies in production. AI-powered systems can predict potential defects early in the lithography process by analyzing patterns in the data collected from previous fabrication runs. Using machine learning algorithms, these systems can learn to identify subtle patterns or anomalies that could indicate an impending defect, even before it occurs.

By predicting these issues in advance, AI enables manufacturers to take corrective actions before defects affect production, ensuring higher yields and reducing costly rework.

4. Accelerating Design for Manufacturability

The shift toward smaller nodes and more advanced chip designs has made it increasingly important to design chips that can be efficiently manufactured. AI is playing a critical role in the design for manufacturability (DFM) process, which ensures that the designs of semiconductor devices are optimized for production. AI algorithms can analyze the design and predict how it will interact with the EUV process, helping designers make adjustments that will improve manufacturability without sacrificing performance.

AI can also assist in routing and optimizing transistor placement, making it easier to work within the constraints of EUV lithography and ensuring that designs can be translated into high-quality physical devices.

5. Improving Yield and Reducing Cost

The primary goal of any semiconductor fabrication process is to maximize yield and minimize cost. By using AI to optimize various aspects of the EUV process—such as exposure, alignment, and metrology—chipmakers can reduce defects and improve yield. AI’s predictive capabilities help manufacturers fine-tune every step of the production process, from design to testing, which results in fewer defects and more efficient use of materials.

Ultimately, AI-powered EUV lithography leads to lower costs for semiconductor production, making it economically feasible to produce cutting-edge chips at scale.

The Future of AI-Powered EUV Lithography

As semiconductor production continues to push toward more advanced nodes (below 5nm and eventually to 3nm and beyond), the role of AI in EUV lithography will become even more crucial. With AI’s ability to process and analyze enormous amounts of data, its integration into every aspect of semiconductor manufacturing will enable faster, more efficient production of chips with even higher performance.

In the future, AI is expected to drive even more advanced capabilities, such as autonomous defect detection, real-time process adjustments, and even more sophisticated optimization techniques. As EUV lithography matures, AI will continue to evolve alongside it, enabling chipmakers to produce faster, smaller, and more powerful chips while improving yields and reducing costs.

AI is rapidly becoming an essential tool in the semiconductor industry, especially in the context of Extreme Ultraviolet (EUV) lithography. By optimizing processes, enhancing defect detection, and improving design for manufacturability, AI is helping chipmakers overcome the challenges of producing next-generation semiconductors. As AI continues to evolve, it will unlock new possibilities for EUV lithography, enabling the production of even more advanced chips that will power the technologies of tomorrow. From smart devices to artificial intelligence, the future of technology depends on the innovations made possible by AI-powered EUV lithography.

FAQ: AI-Powered Extreme Ultraviolet Lithography (EUV)

1. What is Extreme Ultraviolet (EUV) lithography? EUV lithography is an advanced photolithographic technique used in semiconductor manufacturing. It uses light with a very short wavelength (13.5 nm) to create intricate patterns on silicon wafers, enabling the production of smaller, more powerful chips at advanced nodes (such as 7nm and below). This process is critical for producing next-generation semiconductors.

2. How does AI improve the EUV lithography process? AI improves EUV lithography by optimizing various stages of the semiconductor manufacturing process, including mask design, patterning, defect detection, and process control. AI algorithms analyze vast amounts of data from previous production runs to predict and prevent potential issues, optimize exposure settings, and increase overall yield and efficiency.

3. What role does AI play in mask design for EUV? AI helps optimize mask design by simulating how different masks will interact with EUV light. It identifies potential patterning issues before they occur, allowing designers to make adjustments that minimize defects and improve the accuracy of the final product. This significantly speeds up the design process and reduces the need for trial and error.

4. How does AI enhance the metrology and process control in EUV lithography? AI improves metrology and process control by continuously monitoring critical process parameters like focus, exposure dose, and temperature. It uses machine learning to detect anomalies and predict potential issues, enabling real-time adjustments to maintain optimal conditions. This results in higher precision and fewer defects in the final semiconductor products.

5. Can AI prevent defects in EUV lithography? Yes, AI can predict and prevent defects by analyzing historical process data to detect patterns or anomalies that could indicate an impending defect. AI systems can anticipate problems such as underexposure, misalignment, or unwanted patterning, allowing for corrective actions before they impact production, leading to higher yields and fewer reworks.

About MarketsandMarkets™

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ’GIVE Growth’ principle, we work with several Forbes Global 2000 B2B companies – helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103

Delray Beach, FL 33445

USA : 1-888-600-6441