Machine safety is a fundamental aspect of industrial operations, ensuring the protection of workers, minimizing downtime, and maintaining regulatory compliance. As industries continue to embrace automation and digital transformation, the machine safety market is witnessing significant growth. However, alongside opportunities, the industry also faces notable challenges. This article explores the key drivers fueling the market, the challenges hindering its progress, and the emerging technologies shaping the future of machine safety.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=1188

Key Drivers of the Machine Safety Market

- Stringent Regulatory Requirements

Governments and regulatory bodies worldwide are imposing stricter safety standards to reduce workplace accidents. Compliance with international safety standards such as ISO 13849, IEC 62061, and OSHA regulations is mandatory for manufacturers, driving the adoption of advanced safety solutions. - Rise of Industrial Automation

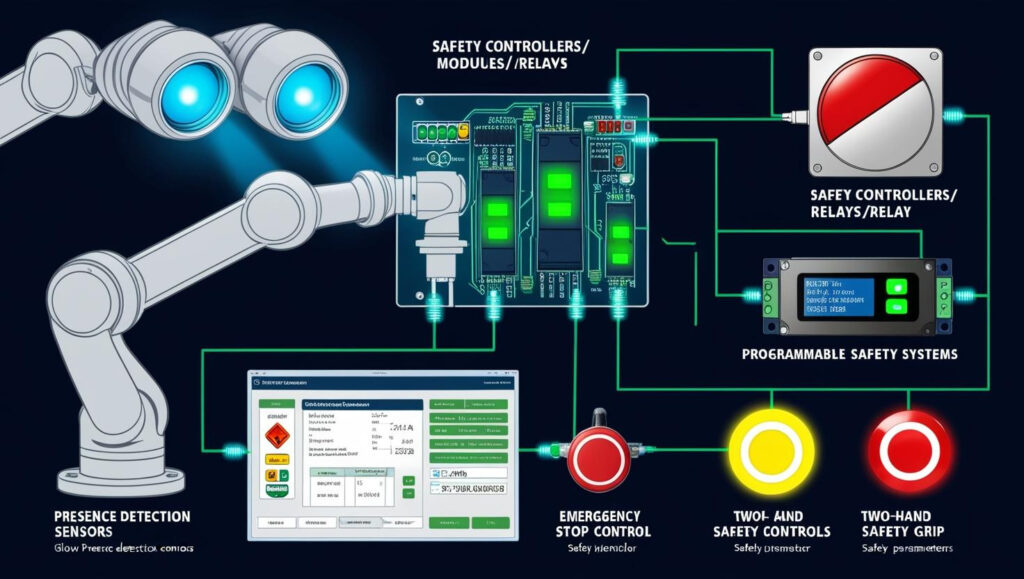

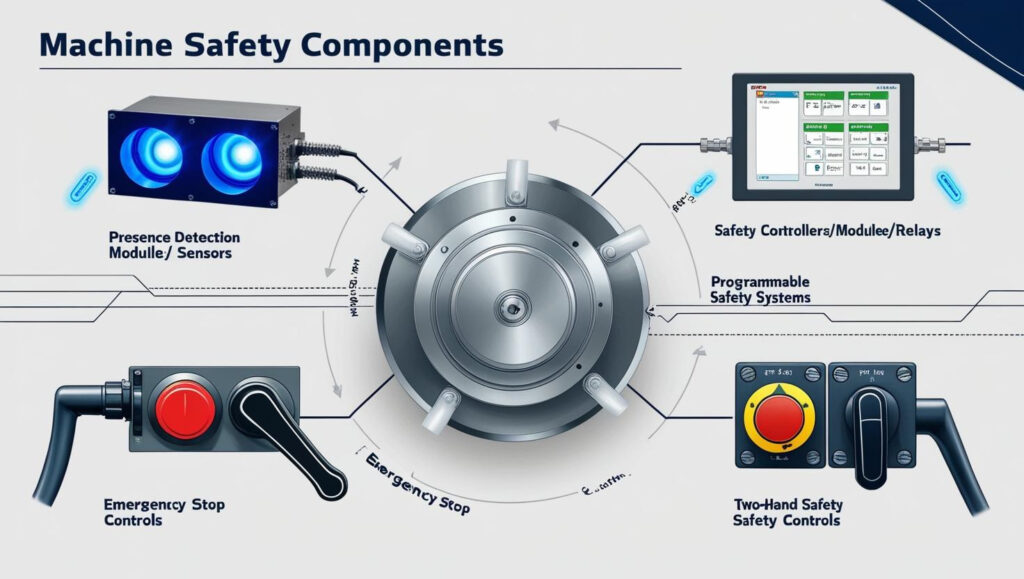

The growing implementation of Industry 4.0 and smart manufacturing practices is increasing the need for machine safety systems. As factories integrate robotic systems and automated machinery, the demand for safety sensors, interlocks, and controllers is rising. - Increasing Workplace Safety Awareness

Organizations are prioritizing worker safety due to rising concerns over employee well-being and productivity. The emphasis on reducing accidents and ensuring safe work environments is driving investment in advanced machine safety solutions. - Growth in High-Risk Industries

Sectors such as oil & gas, mining, construction, and heavy machinery manufacturing require robust safety solutions to mitigate risks. The need for automated safety systems in these industries is contributing to market growth. - Adoption of Collaborative Robots (Cobots)

The rise of cobots, which work alongside human operators, is increasing the need for enhanced machine safety mechanisms. Advanced safety features, including motion detection and real-time hazard assessment, are becoming essential in collaborative workspaces.

Challenges in the Machine Safety Market

- High Implementation Costs

Deploying advanced machine safety solutions involves significant investment in hardware, software, and employee training. Small and medium-sized enterprises (SMEs) often struggle with budget constraints, limiting market penetration. - Complexity of Integration

Integrating safety systems with existing industrial automation infrastructure can be challenging. Ensuring seamless compatibility between new safety technologies and legacy systems requires time and expertise. - Lack of Skilled Workforce

The shortage of trained professionals who can design, implement, and maintain machine safety systems is a major hurdle. Organizations need to invest in workforce training and upskilling to overcome this challenge. - Cybersecurity Risks

As machine safety solutions become increasingly connected through IoT and cloud-based platforms, cybersecurity threats are emerging as a major concern. Protecting safety systems from cyberattacks is critical to preventing operational disruptions.

Emerging Technologies in Machine Safety

- Artificial Intelligence (AI) and Machine Learning

AI-powered safety systems can analyze data from sensors and predict potential hazards before they occur. Machine learning algorithms improve safety measures by identifying patterns and optimizing preventive actions. - Internet of Things (IoT) and Smart Sensors

IoT-enabled safety devices provide real-time monitoring and remote diagnostics. Smart sensors detect machine abnormalities, enabling proactive maintenance and reducing the risk of equipment failures. - Augmented Reality (AR) for Safety Training

AR-based training programs allow workers to experience virtual simulations of hazardous scenarios, improving their preparedness and response to emergencies. - Wireless and Cloud-Based Safety Solutions

Wireless connectivity and cloud integration enhance machine safety by enabling remote monitoring, data analytics, and real-time alerts, ensuring a safer industrial environment. - Wearable Safety Technology

Smart wearables equipped with biometric sensors and haptic feedback mechanisms are being introduced to enhance worker safety by providing real-time alerts in hazardous conditions.

The machine safety market is undergoing rapid transformation due to technological advancements, regulatory pressures, and the increasing need for workplace safety. While challenges such as high costs and cybersecurity risks persist, the integration of AI, IoT, and AR is revolutionizing safety solutions. As industries continue to adopt automation and digitalization, the demand for advanced machine safety technologies will rise, ensuring safer and more efficient industrial environments.