The Asia-Pacific (APAC) region is becoming a hub for cutting-edge advancements in manufacturing, engineering, and quality control, and at the heart of this transformation lies 3D metrology. As industries in APAC increasingly prioritize precision, efficiency, and automation, the demand for 3D metrology solutions has surged. These technologies play a pivotal role in ensuring that products meet stringent quality standards by providing highly accurate, real-time measurements across various sectors.

The Asia-Pacific 3D metrology market is experiencing dynamic growth, driven by innovations in measurement technologies and expanding applications across a wide range of industries.

Explores the key innovations in 3D metrology technologies and their diverse applications in the Asia-Pacific market, showcasing how these advancements are shaping the future of manufacturing and quality control in the region.

1. Revolutionizing Measurement with Advanced 3D Metrology Technologies

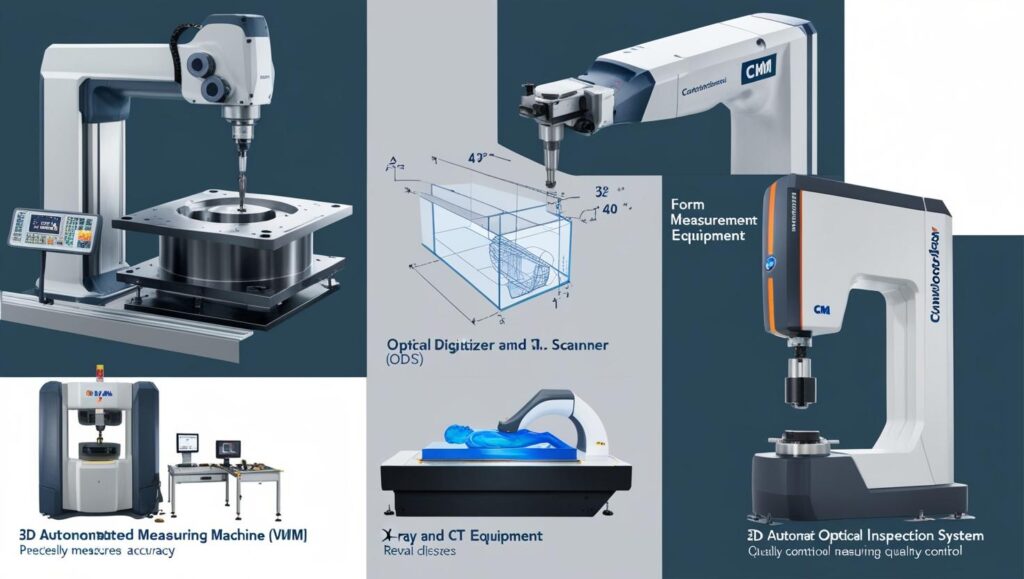

The rapid evolution of measurement technologies is one of the primary factors propelling the growth of the 3D metrology market in Asia-Pacific. As industries push for higher accuracy and faster data collection, traditional measurement methods are being replaced by more sophisticated, digital solutions. Some of the key innovations in 3D metrology technology include:

Laser Scanning and Optical Measurement Systems

Laser scanning technology is among the most significant innovations in 3D metrology, offering high-speed, non-contact measurement capabilities. Laser scanners are able to capture millions of data points in just seconds, providing precise three-dimensional representations of objects. This is particularly valuable in industries where large or complex components need to be measured quickly and accurately, such as aerospace, automotive, and heavy machinery manufacturing.

Optical measurement systems, including structured light and photogrammetry, are also gaining popularity. These systems use light patterns to capture highly detailed 3D data, making them ideal for inspecting intricate components with fine features. The ability to measure objects without physically touching them improves speed, reduces the risk of damage to sensitive components, and increases overall efficiency.

Portable 3D Measurement Devices

Portable 3D measurement devices are rapidly gaining traction across various industries, providing greater flexibility for on-site inspections. These portable systems, such as handheld 3D scanners and portable coordinate measuring machines (CMM), allow manufacturers to collect real-time measurements in challenging environments without compromising accuracy. For example, industries like shipbuilding, construction, and energy rely on portable 3D measurement tools to inspect large structures and machinery on-site, reducing the need for costly downtime and enabling quicker decision-making.

With the rise of portable devices, manufacturers can streamline their quality control processes, cut inspection times, and enhance the overall agility of their operations.

Automated and Robotic 3D Metrology

Automation and robotics have become essential to modern manufacturing processes, and 3D metrology is no exception. Automated metrology systems and robotic arms equipped with 3D measurement tools are capable of conducting high-precision inspections with minimal human intervention. These systems are designed to carry out repetitive tasks consistently and with high accuracy, making them ideal for large-scale production environments.

For example, in the automotive sector, robotic arms fitted with laser scanners and CMMs are increasingly used to inspect car bodies during assembly. These automated systems can quickly detect any deviations or defects in the product, ensuring that it meets the required specifications without slowing down production lines.

Download PDF Brochure @

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=203080758

2. Expanding Applications Across Industries

3D metrology is finding applications across a wide variety of industries in the Asia-Pacific region. From automotive and aerospace to electronics and medical devices, these technologies are revolutionizing quality control and product development. Below are some of the key sectors where 3D metrology is having a profound impact.

Automotive Industry

The automotive industry is one of the largest adopters of 3D metrology technologies in Asia-Pacific. As car manufacturers strive for higher levels of precision and efficiency, they rely on 3D metrology to inspect and measure components with exceptional accuracy. Components such as engine parts, body panels, and chassis are measured in real-time to ensure that they meet safety and performance standards.

Laser scanning, optical systems, and portable CMMs are frequently used for tasks such as part alignment, body-in-white inspection, and assembly verification. Additionally, as electric vehicles (EVs) and autonomous vehicles (AVs) gain popularity, the demand for highly precise measurement systems will continue to rise, making 3D metrology an even more critical tool for automotive manufacturers in the region.

Aerospace and Defense

Aerospace is another industry where precision is non-negotiable, and 3D metrology industry solutions are helping manufacturers maintain high standards of quality. Aircraft components, such as turbine blades, fuselage sections, and engine assemblies, require extremely accurate measurements to ensure they meet strict regulatory standards.

3D metrology tools, such as laser trackers and CMMs, are used to inspect large, complex parts, while optical measurement systems help capture fine details in components with intricate geometries. With the growing demand for advanced aircraft technologies and the expansion of the commercial aviation sector in Asia-Pacific, the role of 3D metrology will continue to grow in the aerospace and defense sectors.

Electronics and Semiconductor

In the electronics and semiconductor industries, products are becoming smaller, more complex, and more powerful. To maintain their performance and reliability, manufacturers need highly accurate and reliable measurement tools. 3D metrology is essential in the inspection of microchips, printed circuit boards (PCBs), and other electronic components.

For instance, semiconductor wafer inspection and microelectromechanical systems (MEMS) testing require incredibly precise measurements to ensure that even the smallest components meet design specifications. 3D optical measurement systems and surface scanners are commonly used for non-destructive testing and high-resolution inspections in these applications.

Medical Device Manufacturing

The medical device industry is experiencing significant growth in the Asia-Pacific region, driven by an aging population and an increased focus on healthcare technologies. 3D metrology is critical in the manufacturing of medical devices such as implants, prosthetics, and diagnostic equipment, where precision is paramount.

3D scanning and measurement systems are used to ensure that parts are manufactured to exact specifications, particularly for customized medical devices. Additionally, the ability to create detailed 3D models of patient-specific implants, based on scans or imaging data, has opened up new possibilities for personalized healthcare solutions.

Consumer Goods and Appliances

In the consumer goods industry, 3D metrology tools are increasingly used to improve product quality and design. Whether in the production of home appliances, electronic gadgets, or furniture, metrology systems are used for quality control, part alignment, and assembly verification. With rising consumer expectations for product performance and durability, manufacturers in the consumer goods sector are turning to 3D metrology to ensure that their products meet the highest standards.

3. The Role of Software in 3D Metrology

One of the key drivers of innovation in 3D metrology is the integration of advanced software solutions that allow users to analyze and interpret measurement data in real time. These software platforms offer powerful features, such as:

Automated inspection and defect detection: Advanced algorithms can automatically identify defects, deviations, or dimensional errors in real-time, allowing for quicker corrective action.

Digital Twin creation: 3D metrology systems are increasingly being paired with software that generates digital twins of physical products, allowing manufacturers to simulate product performance and make improvements before physical prototypes are produced.

Cloud-based data analysis: Cloud-based platforms are enabling manufacturers to store, share, and analyze large volumes of metrology data, facilitating collaboration and decision-making across teams and locations.

The Future of the Asia-Pacific 3D Metrology Market

The Asia-Pacific 3D metrology market is experiencing rapid growth as industries in the region embrace precision, automation, and technological advancements. Innovations in 3D measurement technologies, including laser scanning, optical measurement systems, portable devices, and automation, are transforming how manufacturers approach quality control and product development.

With expanding applications across sectors such as automotive, aerospace, electronics, and medical devices, 3D metrology is becoming an essential tool for maintaining the high standards of quality and performance demanded by today’s consumers and industries. As the market continues to evolve, the integration of advanced software, AI, and automation will further enhance the capabilities of 3D metrology, driving future innovations and shaping the future of manufacturing in the Asia-Pacific region.

The key companies offering 3D metrology companies solutions include:

Hexagon AB (Sweden), ZEISS Group (Germany), FARO (US), Mitutoyo Corporation (Japan), KEYENCE CORPORATION (Japan), KLA Corporation (US), Renishaw plc (UK), and Nikon Corporation (Japan) among others.