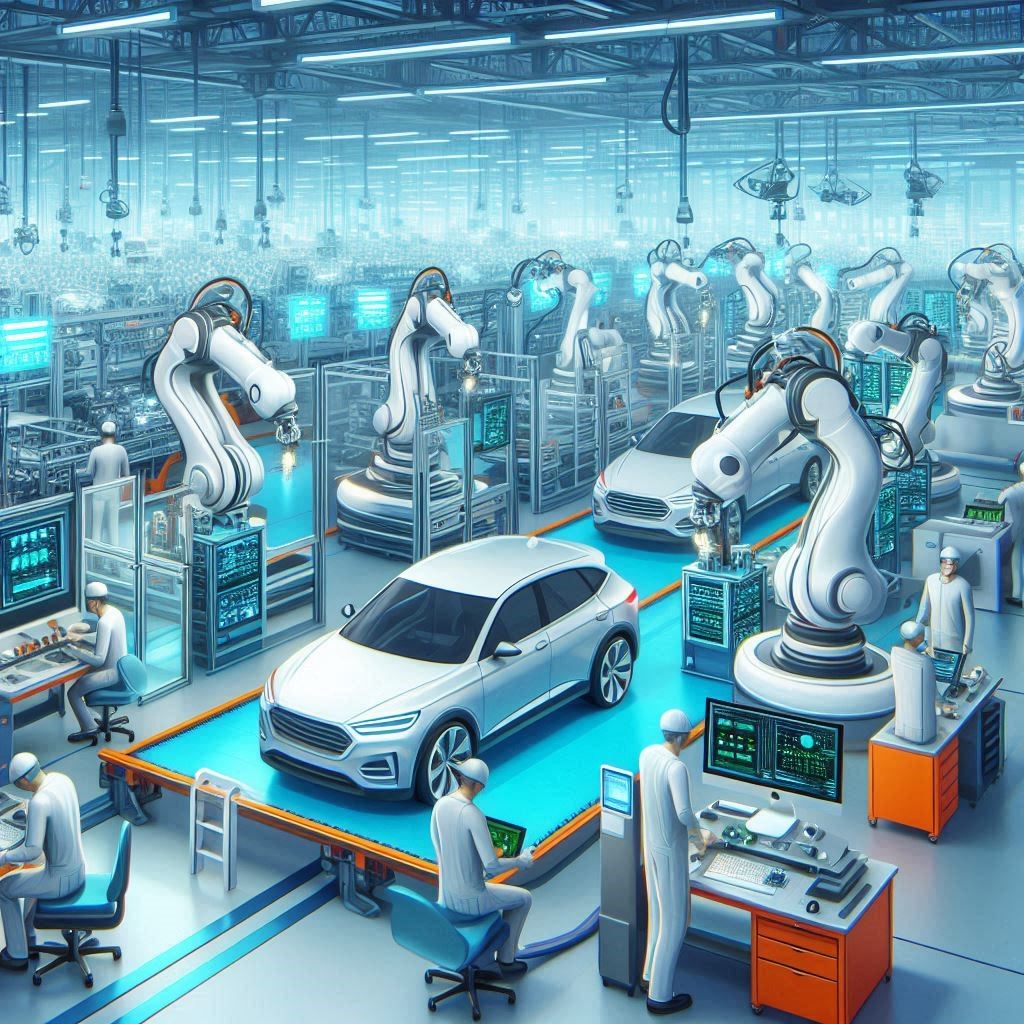

The collaborative robots (cobots) industry is rapidly evolving, driven by advancements in technology and increasing demand for flexible, efficient automation solutions. Unlike traditional industrial robots, cobots are designed to work alongside humans in shared workspaces, enhancing productivity and safety. This article explores the future of the collaborative robots industry, focusing on the benefits, applications, challenges, future trends, and how cobots compare to traditional robots.

Benefits of Collaborative Robots

1. Enhanced Flexibility and Adaptability:

- Easy Programming and Reconfiguration: Cobots are designed for ease of use, with intuitive programming interfaces that allow for quick reconfiguration. This flexibility makes them ideal for dynamic production environments where tasks and processes frequently change.

- Seamless Integration: Unlike traditional robots that may require extensive modifications to existing workflows, cobots can be easily integrated into existing production lines without major disruptions.

2. Improved Safety and Collaboration:

- Safe Human-Robot Interaction: Cobots are equipped with advanced safety features such as sensors and collision detection systems that ensure safe interaction with human operators. These safety measures reduce the risk of accidents and enable cobots to work alongside humans without the need for safety cages.

- Enhanced Worker Productivity: By handling repetitive, dangerous, or physically demanding tasks, cobots allow human workers to focus on more complex and value-added activities, thereby improving overall productivity and job satisfaction.

3. Cost-Effectiveness:

- Lower Initial Investment: Cobots typically have a lower upfront cost compared to traditional industrial robots. Their ease of programming and integration also reduces the need for extensive training and downtime, leading to a faster return on investment.

- Reduced Operational Costs: Cobots’ ability to operate in a collaborative manner reduces the need for additional safety infrastructure and allows for more efficient use of space, contributing to lower overall operational costs.

Industry Growth for Collaborative Robots

The Collaborative Robot industry size is projected to grow from USD 1.9 billion in 2024 and is estimated to reach USD 11.8 billion by 2030; it is expected to grow at a Compound Annual Growth Rate (CAGR) of 35.2% from 2024 to 2030. The growth of the Collaborative Robot industry is driven by higher return on investment than traditional industrial robotic systems; increased demand in e-commerce and logistics sectors; significant benefits in businesses of all sizes; easy programming of cobots.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=194541294

Applications of Collaborative Robots

1. Manufacturing and Assembly:

- Precision Assembly: Cobots are used in precision assembly tasks, such as electronics manufacturing and small parts assembly, where their accuracy and repeatability enhance product quality.

- Material Handling: In manufacturing environments, cobots assist with material handling tasks, including loading and unloading, parts sorting, and palletizing, improving efficiency and reducing manual labor.

2. Healthcare and Laboratories:

- Laboratory Automation: In laboratories, cobots handle repetitive tasks such as sample analysis, pipetting, and data logging, allowing researchers to focus on more critical tasks and increasing overall productivity.

- Patient Assistance: Cobots in healthcare settings can assist with tasks such as patient lifting and positioning, providing support to medical staff and improving patient care.

3. Retail and Customer Service:

- Inventory Management: Cobots are used in retail environments for tasks such as stock replenishment and inventory management. They can quickly sort and shelve items, reducing labor costs and improving inventory accuracy.

- Customer Interaction: In customer service, cobots can assist with tasks such as greeting customers, answering questions, and providing information, enhancing the overall customer experience.

Challenges in Implementing Collaborative Robots

1. Integration with Existing Systems:

- Compatibility Issues: Integrating cobots with existing systems and processes can sometimes be challenging, particularly in legacy systems that were not designed with cobots in mind. Ensuring compatibility requires careful planning and potential modifications to existing workflows.

2. Training and Skill Development:

- Operator Training: While cobots are designed to be user-friendly, effective implementation still requires proper training for operators and maintenance personnel. Ensuring that staff are adequately trained to work with cobots is essential for successful deployment.

3. Safety and Reliability Concerns:

- Maintaining Safety Standards: Despite their safety features, cobots must be properly maintained to ensure they continue to operate safely. Regular inspections and updates to safety protocols are necessary to prevent accidents and ensure reliable performance.

Future Trends in the Collaborative Robots Industry

1. Advanced AI and Machine Learning Integration:

- Enhanced Autonomy: The integration of artificial intelligence (AI) and machine learning will enable cobots to perform more complex tasks autonomously and adapt to changing environments. AI-driven cobots will enhance their ability to learn from experience and improve their performance over time.

2. Increased Connectivity and IoT Integration:

- Smart Factories: The future of cobots will see increased integration with Internet of Things (IoT) platforms, enabling real-time data exchange and connectivity across production systems. IoT-enabled cobots will provide valuable insights into performance and operational efficiency.

3. Collaborative Human-Robot Teams:

- Advanced Collaboration: Future cobots will be designed to work more seamlessly in collaborative human-robot teams, with enhanced communication and coordination capabilities. This will improve the efficiency and effectiveness of human-robot interactions.

4. Expansion into New Industries:

- Diverse Applications: As technology advances, cobots will find applications in new industries and sectors, such as agriculture, construction, and aerospace. The adaptability and flexibility of cobots will drive their adoption in diverse and emerging fields.

Collaborative Robots vs Traditional Robots

1. Flexibility and Adaptability:

- Cobots: Collaborative robots are designed to be flexible and easily reconfigurable, making them suitable for a wide range of tasks and environments. They can be quickly programmed and adapted to new applications.

- Traditional Robots: Traditional industrial robots often require extensive reconfiguration and programming for each new task, making them less adaptable to changes in production processes.

2. Safety and Collaboration:

- Cobots: Cobots are built with safety features that allow them to work alongside human operators without the need for safety cages. Their design promotes safe and collaborative interactions.

- Traditional Robots: Traditional robots typically operate in isolation, with safety barriers and enclosures required to protect human workers from potential hazards.

3. Cost and Investment:

- Cobots: Cobots generally have a lower initial investment and operational costs due to their ease of use and integration. They offer a cost-effective solution for automation in various industries.

- Traditional Robots: Traditional robots often involve higher upfront costs and require significant investment in safety infrastructure and specialized training.

The future of the collaborative robots industry is bright, with ongoing advancements in technology driving increased adoption and expanding applications. Cobots offer numerous benefits, including flexibility, safety, and cost-effectiveness, making them an attractive option for a wide range of industries. As the industry continues to evolve, the integration of advanced AI, IoT, and other emerging technologies will further enhance the capabilities of cobots, leading to more efficient and effective automation solutions. The continued development and adoption of collaborative robots will transform industries, improve productivity, and support the growth of a more connected and intelligent manufacturing landscape

Trackbacks