The Motor monitoring market is projected to reach USD 3.5 billion by 2028 from an estimated USD 2.3 billion in 2023, at a CAGR of 8.7% during the forecast period. Motor monitoring is one of the aspects of predictive maintenance that tracks the performance of motors to minimize downtime needed for repairs. The failing machinery is predicted by monitoring the vibration or temperature of the motor case or the bearings. Motor monitoring is required in various sectors, including oil and gas, power generation, automotive, energy and power, mining, food and beverage, chemicals, and other sectors. Technological advancements in motor monitoring include the use of motor current signature analysis (MCSA) technology, which analyzes motor currents rather than relying on traditional vibration-monitoring techniques.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=142439618

Hardware, by Offering, is expected to grow by the largest segment during the forecast period.

Based on the offering, the motor monitoring market has been split into hardware, software and services. Hardware is the most important component of a machine condition monitoring system. The hardware segment mainly includes vibration sensors, infrared sensors, ultrasound detectors, spectrum analyzers, and corrosion probes. They mitigate risks, boost safety, and reduce maintenance costs, along with improving reliability, uptime, and efficiency. These features are driving the products market for the Hardware segment.

The online segment, by monitoring process, is expected to grow at the fastest CAGR during the forecast period.

This report segments the motor monitoring market based on monitoring process; the motor monitoring market has been segmented into online and offline/portable processes. Online motor monitoring systems track machine vibration, misaligned couplings and unbalance, air gap variation, broken rotor bars, bearing fluting, and other relevant machine condition parameters throughout the life of the asset. High-voltage (HV) motors are generally equipped with online motor monitoring in several industries such as oil & gas, power generation, water transportation, metals, and mining. The declining costs of sensors and submeters, and the advent of big data analytics have made online motor monitoring solutions increasingly accurate and affordable. Such factors drive the growth of the online motor monitoring market.

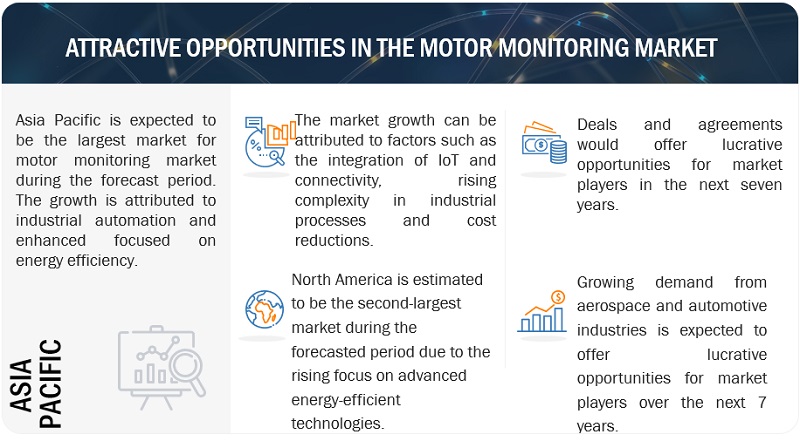

North America is expected to be the second largest region in the motor monitoring market.

North America is expected to be the second-largest motor monitoring market during the forecast period. The North American region has been subdivided into three key countries: US, Canada, and Mexico. Motor monitoring solutions are crucial to industries as they have the capability to accurately predict plant failure, which helps organizations reduce their maintenance and operational expenses. Constant advancements in motor monitoring software, increased R&D in the field of IoT and IIoT, and increasing demand for efficient and cost-effective technologies to improve motor performance and optimize business operation by preventing motor failure are also supporting the growth of the market in region.

Make an Inquiry: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=142439618

Key Players

Some of the major players in the motor monitoring market are Dynarpar (US), KCF Technologies (US), Pheonix Contact (Germany), Allied Reliability (US), and KONCAR (Croatia). The major strategies adopted by these players include sales contracts, product launches, investments, collaborations, partnerships, and expansions.