The market size of waste heat recovery system (WHRS) was USD 44.14 Billion in 2015, and is projected to reach USD 65.87 Billion by 2021, at a CAGR of 6.90%. Rising energy & electricity prices coupled with stringent government regulations & incentives are expected to drive the market in the future.

Waste heat recovery is the process of capturing residual heat from an existing industrial process and using it for other applications. Waste heat refers to the energy generated by various industrial processes. WHR technologies help in reducing the costs of operating facilities by enhancing their energy productivity. The energy recovered during this process is widely used in two major applications, namely, steam & electricity generation and preheating.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=202657867

Petroleum refining

WHRSs are widely used in petroleum refining processes such as distillation (fractionation), thermal cracking, catalytic, and treatment. The thermal effectiveness of these energy-intensive processes is crucial to the petroleum refining industry and, hence, highly energy efficient WHRS are used for such applications. Many exothermic reactions occur in the refineries that also produce waste heat. Some modern refineries have highly integrated systems that recover heat from one process to use in other processes. However, still many refineries and their operations release high-temperature waste heat, but lack efficient WHRS to recover it for different applications. The growing oil & gas industries in the Asia-Pacific region, and increasing oil production in the Middle East & Africa is driving the demand of WHRS in petroleum refining industry globally.

Chemical

WHRS have been successfully used in the chemical industry for processes such as industrial gases, alkalis and chlorine, cyclic crudes, and intermediates, including ethylene, propylene, benzene/toluene, plastics materials, synthetic rubber, synthetic organic fibers, and agricultural chemicals. High efficiency, operational productivity, and utilization of specialized and customized equipment have made WHRS an important component in chemical production processes. Therefore, growth in the chemical industry is one of the driving factors of the global WHRS market.

Metal Production

Heavy metals manufacturing and refining involves many high-temperature processes from which waste heat can be recovered. Heavy metal foundries commonly recover clean gaseous streams. However, recovering waste heat from heavily contaminated exhaust gas sources such as coke ovens, blast furnaces, basic oxygen furnaces, and electric arc furnaces continue to present a challenge for economical functioning of WHRS. Other sources of waste heat include melting furnace exhaust, ladle preheating, core baking, pouring, shot blasting, castings cooling, heat treating, and quenching. The heat recovered from these sources is used in steam and electricity generation in and is further used as fuel in other processes. This helps the low revenue generating metal industry to boost its energy efficiency, and hence reduce operating costs. The demand of WHRS is increasing in metal production segment, as the metal industry is growing heavily in all the regions.

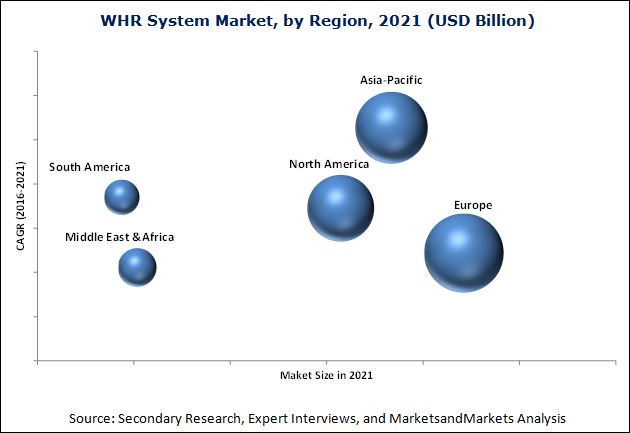

Europe: The largest market in WHRS

The WHR system market is broadly segmented into five regions, namely, North America, Europe, Asia-Pacific, the Middle East & Africa, and South America. Europe is the largest WHR system market, closely followed by North America, in terms of value. Government and environmental organizations in various countries such as the U.S. and European Union have adopted stringent legislations on energy saving and energy efficiency. Even the government in developing regions such as Asia-Pacific and South America are formulating stringent regulations for environment protection. These stringent energy efficiency regulations are driving the use of WHRS in various manufacturing-oriented industries.

Currently, market players such as ABB Ltd. (Switzerland), Amec Foster Wheeler (U.K.), Ormat Technologies Inc. (U.S.), General Electric Co. (U.S.), Mitsubishi Heavy Industries Ltd. (Japan), Echogen Power Systems Inc. (U.S.), Econotherm Ltd. (U.K.), Thermax Limited (India), Siemens AG (Germany), and Cool Energy Inc. (Colorado) dominate the global WHR system market.

Read More: https://www.marketsandmarkets.com/PressReleases/waste-heat-recovery-system.asp