The tariffs imposed during the Trump administration shook up the industrial control and factory automation sectors, causing supply chain disruptions, rising costs, and uncertainty. But as with any major disruption, there’s always a chance to turn things around and come out ahead. In fact, many businesses in this space now have a chance to reinvent themselves, discover new markets, and leverage emerging technologies.

Here’s a look at the top 10 opportunities that the industrial control and factory automation market can seize in the post-tariff era.

1. Bringing Manufacturing Back Home (Reshoring and Nearshoring)

After the tariffs hit, many companies realized how vulnerable they were to global supply chain disruptions. As a result, there’s a growing trend of reshoring (bringing manufacturing back to the U.S.) and nearshoring (moving production closer to home, like to Mexico or Canada).

Why it matters: Bringing production closer to home reduces the risks associated with tariffs and long international shipping times. Plus, it gives businesses more control over quality, costs, and timelines.

2. Embracing Automation Technologies

With costs on the rise, more and more companies are turning to automation as a way to cut back on labor expenses while improving efficiency. Robots, AI, and automated systems are playing a huge role in helping businesses stay competitive.

Why it matters: Automation not only lowers labor costs but also boosts production speed, improves accuracy, and helps companies scale up without having to hire more workers. This is essential in today’s tight labor market.

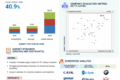

3. Tapping into Emerging Markets

As industries in Asia, Latin America, and Africa grow, there’s an increasing demand for automation solutions. These regions are quickly adopting new technologies to improve productivity and modernize their manufacturing processes.

Why it matters: Expanding into emerging markets offers businesses a whole new pool of customers. By targeting regions that are investing heavily in industrial growth, companies can tap into fresh sources of revenue and growth.

Request Trump Tariff Threat Assessment Analysis Now @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=541

4. Investing in Energy-Efficient and Sustainable Solutions

Sustainability is no longer just a buzzword—it’s a business imperative. With tariffs making certain components more expensive, companies can look for ways to offer energy-efficient and environmentally friendly automation systems.

Why it matters: Energy-efficient automation systems not only help companies cut their energy bills but also align with global sustainability goals. Offering eco-friendly solutions can make your brand more appealing, especially as businesses and consumers become more conscious of their environmental impact.

5. Riding the Wave of Digital Transformation

The push for digital transformation continues to reshape industries. By integrating technologies like AI, IoT, cloud computing, and machine learning into industrial systems, companies can unlock new levels of efficiency and insight.

Why it matters: Embracing these technologies gives businesses the tools to analyze data in real time, optimize operations, and make smarter decisions. These digital upgrades are critical for staying competitive in an increasingly data-driven world.

6. Modular and Scalable Solutions for Flexibility

With tariffs raising component prices, modular and scalable automation solutions are gaining popularity. These systems use standardized parts that can be easily swapped out or expanded as needed, making them more adaptable and cost-effective.

Why it matters: Modular systems reduce upfront costs and allow manufacturers to scale up as their needs evolve. Companies can add more capabilities without investing in a whole new system, making automation more accessible and flexible for different businesses.

7. Collaborative Robots (Cobots) – The Future of Human-Robot Collaboration

Collaborative robots, or cobots, are designed to work alongside human workers, handling repetitive or dangerous tasks. These robots are gaining popularity because they’re relatively affordable, easy to program, and can boost worker safety and productivity.

Why it matters: Cobots offer a great solution for small and medium-sized businesses that want to introduce automation without replacing their entire workforce. They’re a cost-effective way to improve productivity while still maintaining human involvement where it matters most.

8. Leveraging Predictive Maintenance and Data Analytics

As industrial systems become more connected, there’s a massive opportunity to use data analytics and predictive maintenance tools to stay ahead of potential problems. By using sensors and machine data, companies can predict when equipment is likely to fail, allowing for maintenance before a breakdown happens.

Why it matters: Predictive maintenance reduces downtime and repair costs while extending the life of equipment. As tariffs raise the cost of components, it makes even more sense to get the most out of existing machinery by keeping it in peak condition.

9. Strategic Alliances and Partnerships

After the disruptions caused by tariffs, many companies are turning to strategic partnerships to share resources, reduce risks, and access new markets. Collaborating with local suppliers, tech companies, and even competitors can create a stronger, more resilient operation.

Why it matters: Strategic partnerships help businesses lower R&D costs, enter new regions more quickly, and better navigate supply chain disruptions. By pooling resources, companies can stay competitive and grow faster than they could on their own.

10. Taking Advantage of Government and Industry Incentives

Governments are offering more incentives to businesses that invest in automation, energy-efficient technologies, and advanced manufacturing solutions. These incentives can come in the form of tax breaks, grants, and subsidies, which can help companies offset some of the additional costs brought on by tariffs.

Why it matters: By taking advantage of these incentives, businesses can reduce their financial burden and accelerate their adoption of new technologies. This can be especially helpful for smaller businesses looking to innovate without breaking the bank.

Conclusion: Embrace the Opportunity in Disruption

The tariffs may have created hurdles for the industrial control and factory automation market, but they’ve also opened up numerous opportunities. From reshoring production and expanding into emerging markets to embracing automation and digital transformation, companies can harness these changes to build a stronger, more resilient future. By taking advantage of these trends, businesses can not only recover from the challenges posed by tariffs but come out ahead—positioning themselves as leaders in the next era of manufacturing.