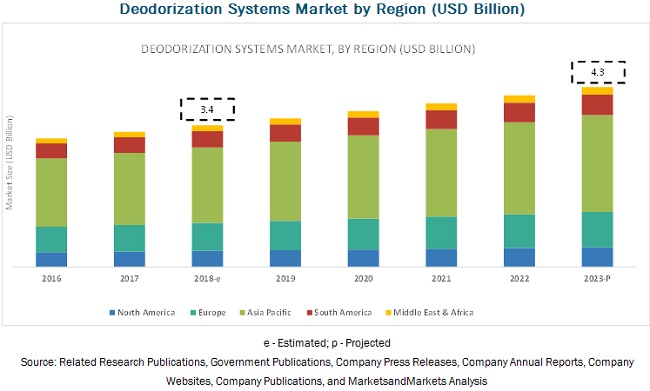

The report “Deodorization Systems Market by Seedoil (Palm Oil, Soybean, Sunflower, Groundnut & Others), Component, Refinery Method (Physical & Chemical), Operation (Batch, Semi, & Automatic), Technique (Thin Film & Packed Column) – Global Forecast to 2023″, is estimated to be valued at USD 3.4 billion in 2018 and is projected to reach a value of USD 4.3 billion by 2023, growing at a CAGR of 4.9% during the forecast period. Factors such as growing demand for higher nutritional value in edible oil and growing industrialization & rapid urbanization are driving the growth of this market.

Report Objectives:

- Determining and projecting the size of the deodorization systems market, with respect to component, technology, seed oil, operation, type, refining method, and regional markets, over a five-year period, ranging from 2018 to 2023

- Identifying attractive opportunities in the market by determining the largest and fastest-growing segments across the key regions

- Identifying and profiling prominent market players in the market

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=261682843

By technology, the packed column segment is projected to be the fastest-growing segment in the deodorization systems market during the forecast period.

The packed column segment in the market is projected to be the fastest-growing segment as packed column technology employs a dual temperature system, which allows the deodorizer to operate in two different temperatures. This enables the system to achieve a better balance in terms of the residence time for deodorization, thereby allowing the deodorization equipment to process edible oils at various temperature and pressure requirements.

By refining method, the chemical refining segment is projected to dominate the deodorization systems during the forecast period.

The chemical refining segment is projected to hold the largest market share in the deodorization systems during the forecast period as it is relatively an efficient method for reducing the fatty acid content in the crude oil with higher boiling point. This method is used in order to treat the oil with high free fatty acid content.

Middle East & Africa is projected to grow at the highest CAGR of 5.7% during the forecast period

Middle East & Africa provides the highest potential for growth due to rise in developments in deodorization equipment & technology and increased industrial activities in this region. In South Africa, the increasing number of edible oil refineries is a major factor for the growth of this industry. Easing regulations from the government and improvements in cultivation policies are expected to have a profound impact on the deodorization systems market in this region. In Middle Eastern countries, the edible oil refineries and deodorization columns are being installed as a result of foreign collaborations and local partnerships, undertaken in an effort to reduce costs and scale up production. These all factors are resulting in higher growth in the deodorization systems market in this region.

Request for Customization: https://www.marketsandmarkets.com/requestCustomizationNew.asp?id=261682843

This report includes a study on the marketing and development strategies, along with a study on the product portfolios of the leading companies operating in the deodorization systems market and offering various deodorization solutions. It includes the profiles of leading companies such as Alfa Laval AB (Sweden), Desmet Ballestra (Belgium), Crown Iron Works (US), Compro International (Canada), Zhengzhou Sunshine Machinery Co. Inc. (China), Luohe Zhonzhiyuan Grains & Oil Machinery Co. Inc (China), Myande Group (China), Goyum Screw Press Pvt. Ltd. (India), HUM Oil and Fat Technologies (Turkey), Andreotti Impianti S.p.A (Italy), DVC Process Technologists Pvt. Ltd. (India), and Gianazza International S.p.A. (Italy).

Recent Developments:

- In May 2018, Myande Group launched a 3D design application for its oil and fat engineering products, which included all technologies and derivatives associated with the market. The launch of 3D design applications would ensure a faster and more accurate design process aimed toward eliminating any design errors and improving client interaction to ensure smoother workflow, observe dynamic changes, and highlight future problems.

- In April 2018, Desmet Ballestra announced its plan to invest in the R&D department to develop new sustainable processes, optimize designs & yields, improve health & safety standards, and test new customer applications.