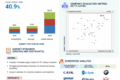

The report “TPE Market by Type (SBC, TPU, TPO, TPV, COPE, PEBA), End Use Industry (Automotive, Building&Construction, Footwear, Wire&Cable, Medical, Engineering), Region (North America, Europe, APAC, South America, MEA) – Global Forecast to 2026″ The global thermoplastic elastomers market size is estimated to be USD 19.9 billion in 2021 and is projected to reach USD 26.3 billion by 2026, at a CAGR of 5.7% between 2021 and 2026.

Thermoplastic elastomers are a class of polymers having properties of both thermoplastics and elastomers. They are obtained by linking thermoplastics with elastomeric rubbers. Thermoplastic elastomers provide advantages of both plastics and rubber, and hence the new form created by their combination is adaptable in many applications. The high impact and tear strength of thermoplastic elastomers have increased their demand in the automotive and building & construction industries. Thermoplastic elastomers are recyclable, environment-friendly, and safe to use in medical and food packaging applications.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=1012

The TPE market is segmented on the basis of application as automotive, building & construction, footwear, wire & cables, medical, engineering, and others. In automotive sector, TPE is used in exterior filler for panels, wipers, rocker panels, body seals, automotive gaskets, door & window handles, other under-the-hood applications. In building & construction, TPE is mainly used as roofing membrane, bitumen modification, roofing membranes, weather-stripping, waterproofing, carpeting, wall coverings, window & weather seals.

Thermoplastic elastomers can be broadly classified into styrene block copolymer (SBC), thermoplastic polyurethane (TPU), thermoplastic polyolefin (TPO), thermoplastic vulcanizate (TPV), polyester ether elastomer (COPE), and polyether block amide (PEBA). Thermoplastic elastomers are among the most innovative products in the elastomers market as they have the functional properties of thermoset rubber and possess the strength of thermoplastics.

The major industry players are adopted acquisitions, expansions, joint venture, and new product development as growth strategies in the last four years. The leading players in the market are Arkema S.A (France), Asahi Kasei Corporation (Japan), BASF SE (Germany), The Dow Chemical Company (The U.S), Covestro AG (Germany), Huntsman Corporation (The U.S), Teknor Apex Company (The U.S), Lubrizol Corporation (The U.S), Tosh Corporation (Japan), Kraton Corporation (The U.S), China Petroleum and Chemical Corporation (China), Mitsubishi Chemical Company (Japan), DuPont (The U.S), SIBUR (Russia), Evonik Industries AG (Germany), Dynasol Elastomers (Spain).

Request Sample: https://www.marketsandmarkets.com/requestsampleNew.asp?id=1012

Arkema is involved in the manufacturing and sales of several chemical products that find applications in consumer goods, paint & coatings, building & construction, automotive & transportation, electronics, energy, and other industries. The company operates business through four segments: adhesive solutions, advanced materials, coating solutions, and intermediates. The company offers thermoplastic elastomers under the advanced materials division. Arkema has 144 production facilities and presence across 55 countries.

BASF SE is chemical conglomerate and has a strong presence across the globe. The company supplies its products through 11 divisions, which are grouped into six segments: chemical, materials, industrial solutions, surface technologies, nutrition & care, and agriculture solutions. The company has a broad portfolio comprising 75 strategic business units. It produces thermoplastic elastomers under the performance material division, within the materials segment. The company operates 6 Verbund sites and 241 production sites across 90 countries. The Verbund concept allows the company to fully integrate the production process, technology, distribution channel, and recently the digital channel; to create efficient value chains that help in saving raw material cost, improve product yield, minimize emission, and lower logistic costs.

Speak to Analyst: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=1012