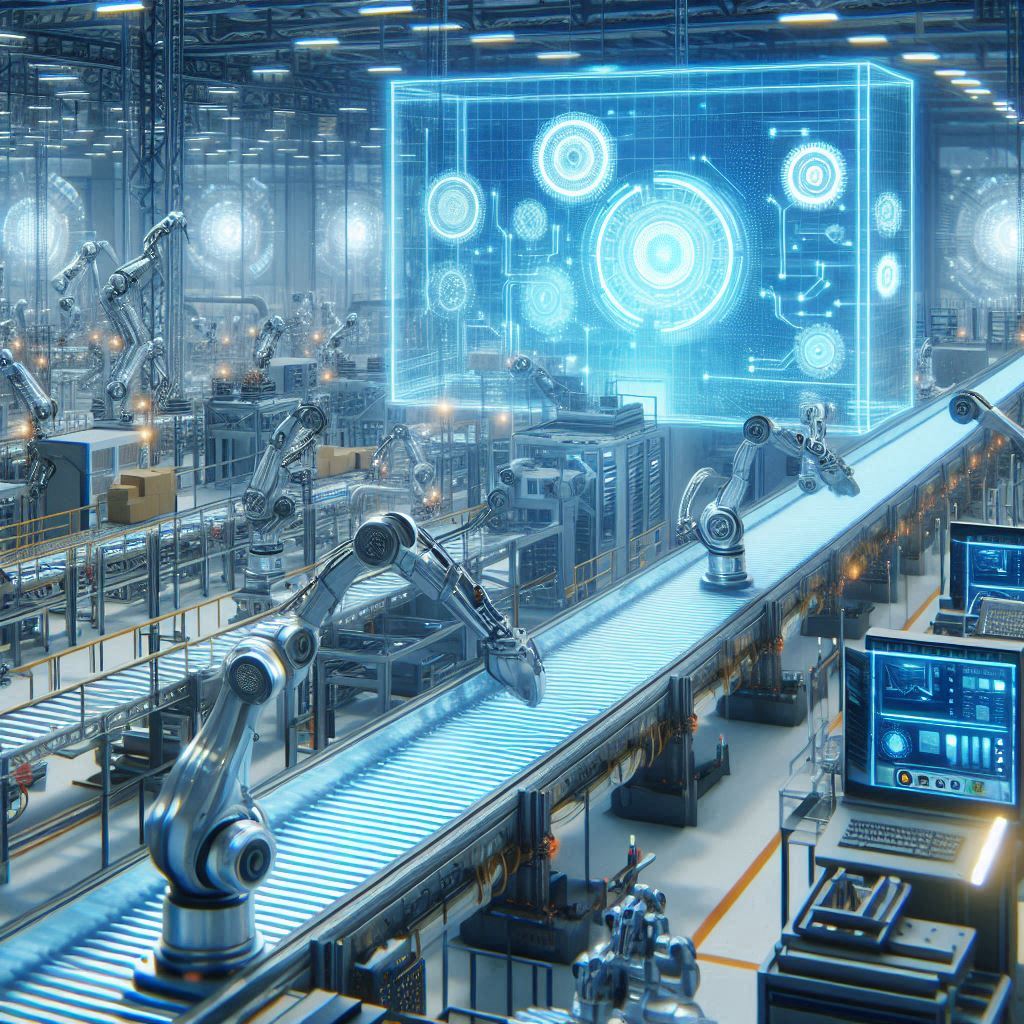

The manufacturing industry is undergoing a rapid transformation, fueled by the adoption of Artificial Intelligence (AI). As AI technologies become more advanced and accessible, they are being integrated into various manufacturing processes to enhance efficiency, optimize operations, and drive innovation. This article explores the growth trends shaping the global AI in manufacturing industry, provides regional insights, and discusses future opportunities for businesses adopting these cutting-edge technologies.

Growth Trends in Artificial Intelligence in Manufacturing Industry

- AI-Powered Automation

The automation of manufacturing processes is one of the primary growth drivers for AI adoption. AI-powered robots and automated systems are being deployed to streamline production lines, reduce human error, and minimize downtime. AI’s ability to analyze real-time data and make immediate adjustments is transforming the efficiency of manufacturing operations, especially in industries with high-volume production. - Rise of Predictive Maintenance

Predictive maintenance is a major trend driving the growth of AI in manufacturing. AI algorithms can analyze data from machines and equipment to predict potential breakdowns before they occur, allowing manufacturers to perform maintenance at optimal times. This not only reduces downtime but also lowers repair costs, extends equipment lifespan, and boosts productivity. - Improved Quality Control

AI is revolutionizing quality control by providing advanced machine vision and image recognition technologies that can detect defects or inconsistencies during production. AI systems can analyze products faster and more accurately than human inspectors, ensuring that quality standards are met without compromising production speed. This trend is particularly significant in sectors like automotive, electronics, and pharmaceuticals. - AI-Driven Supply Chain Optimization

AI is transforming supply chain management by offering real-time insights into demand forecasting, inventory levels, and logistics. Manufacturers can use AI algorithms to optimize production schedules, reduce waste, and enhance just-in-time delivery processes. By improving the efficiency of supply chains, AI helps manufacturers respond quickly to market changes and minimize disruptions. - Human-Robot Collaboration (Cobots)

Collaborative robots, or cobots, are becoming increasingly popular in manufacturing environments. These AI-driven robots are designed to work alongside human workers, augmenting their capabilities and performing repetitive tasks more efficiently. Cobots are particularly valuable in assembly lines, packaging, and other high-volume tasks that benefit from both human oversight and robotic precision.

Regional Insights into the Global AI in Manufacturing Industry

- North America

North America is a leading region for AI adoption in manufacturing, with the U.S. and Canada at the forefront of technological innovation. The region’s strong industrial base, coupled with significant investments in AI research and development, is driving market growth. In addition, the adoption of Industry 4.0 initiatives and the rise of smart factories are accelerating the implementation of AI solutions across various manufacturing sectors. - Asia-Pacific

Asia-Pacific is experiencing the highest growth in AI adoption within the manufacturing industry, with countries such as China, Japan, and South Korea leading the charge. The region’s dominance in electronics, automotive, and semiconductor manufacturing has created a fertile ground for AI integration. China, in particular, is heavily investing in AI-driven manufacturing as part of its “Made in China 2025” initiative, aiming to modernize its manufacturing sector through automation and smart technologies. - Europe

Europe is a significant player in the global AI in manufacturing industry, with Germany spearheading advancements in AI-powered industrial applications. The region’s strong automotive and aerospace industries are driving the adoption of AI technologies for process optimization, predictive maintenance, and automation. Europe is also focused on sustainability, with AI being used to optimize energy consumption and reduce waste in manufacturing. - Latin America

Latin America is beginning to see the benefits of AI in manufacturing, particularly in countries like Brazil and Mexico. The region’s growing industrial base, coupled with an increasing focus on improving productivity and reducing operational costs, is driving AI adoption. However, the lack of infrastructure and limited access to advanced technologies remain challenges for widespread implementation. - Middle East & Africa

The Middle East and Africa are emerging markets for AI in manufacturing. While the adoption rate is slower compared to other regions, countries like the UAE and Saudi Arabia are investing in AI to diversify their economies and build smart manufacturing capabilities. The oil and gas, construction, and food processing industries are particularly poised to benefit from AI-driven innovations in this region.

Future Opportunities in Artificial Intelligence in Manufacturing

- Sustainability and Energy Efficiency

As sustainability becomes a global priority, AI is playing a crucial role in optimizing energy use and reducing carbon emissions in manufacturing processes. AI algorithms can monitor energy consumption in real-time, identifying areas where energy can be saved and emissions reduced. Manufacturers adopting AI-driven sustainability initiatives can not only lower costs but also align with global environmental regulations and customer demand for eco-friendly products. - Customization and Flexibility in Manufacturing

AI is enabling manufacturers to move towards mass customization, where products can be tailored to meet specific customer preferences without disrupting production efficiency. AI-powered systems can adjust manufacturing processes in real-time to accommodate different product designs, materials, and features. This level of flexibility allows manufacturers to offer more personalized products while maintaining scalability. - AI in Smart Factories

The concept of smart factories is gaining traction, with AI at the core of these highly automated, data-driven facilities. In smart factories, AI systems collect and analyze vast amounts of data from interconnected machines and devices, enabling real-time decision-making and process optimization. As more manufacturers invest in smart factory technologies, AI will continue to be a key driver of operational excellence and innovation. - Expansion of AI-Driven IoT in Manufacturing

The Internet of Things (IoT) is revolutionizing manufacturing by connecting machines, devices, and sensors to the internet, enabling real-time data sharing. When combined with AI, IoT provides manufacturers with valuable insights into production processes, equipment health, and supply chain operations. AI-driven IoT solutions will continue to create new opportunities for manufacturers to optimize operations and improve performance. - Workforce Upskilling and Human-Machine Collaboration

As AI becomes more integrated into manufacturing, the need for a skilled workforce capable of working alongside AI technologies will increase. Manufacturers will need to invest in workforce training and upskilling to ensure employees can effectively collaborate with AI-driven machines and systems. Human-machine collaboration will become a cornerstone of future manufacturing operations, enhancing productivity and innovation.

The global AI in manufacturing industry is on a strong growth trajectory, with numerous opportunities for innovation, efficiency gains, and sustainability. As AI technologies continue to advance, manufacturers worldwide are leveraging these tools to stay competitive in a rapidly evolving marketplace. By embracing AI-powered automation, predictive maintenance, quality control, and supply chain optimization, manufacturers can unlock significant value and prepare for the future of intelligent, data-driven manufacturing.