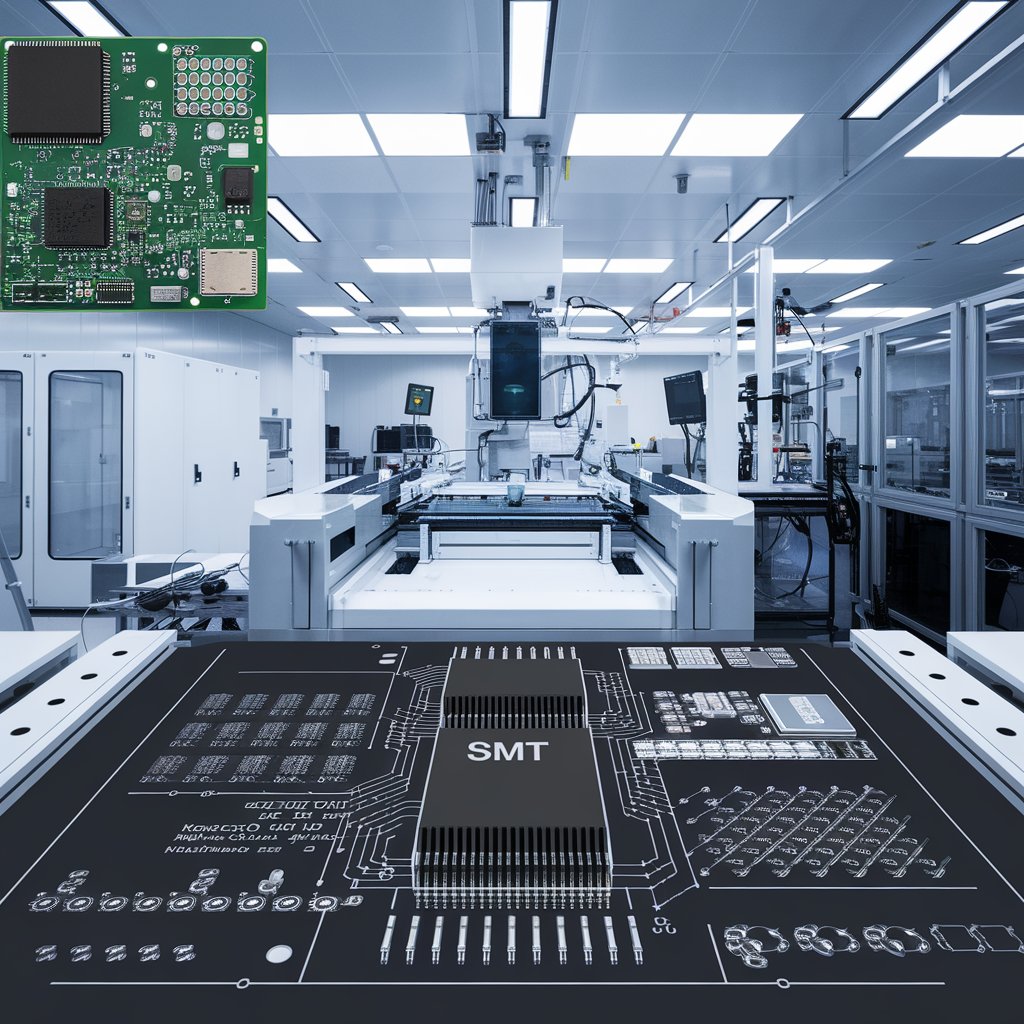

Surface Mount Technology (SMT) has been a cornerstone of modern electronics manufacturing, enabling the miniaturization of components and enhancing production efficiency. As technology continues to evolve, the future of Surface Mount Technology is poised for significant advancements.

The surface mount technology (SMT) market size is projected to grow from USD 5.8 billion in 2023 to reach USD 8.4 billion by 2028; it is expected to grow at a CAGR of 7.8% during the forecast period. Some of the major driving factors for the growth of this market include the increased demand for miniaturized consumer electronics products and the increasing adoption of electric vehicles.

Here are some key trends and developments shaping the future of Surface Mount Technology:

Miniaturization and Increased Component Density

The demand for smaller, lighter, and more efficient electronic devices is driving the trend toward even more compact SMT components. Future surface mount technology designs will likely feature smaller packages, allowing for higher component density on printed circuit boards (PCBs). This miniaturization will be critical for industries like wearables, IoT devices, and mobile technology.

Advanced Materials and Processes

Innovation in materials, such as new solder alloys and substrates, will enhance the reliability and performance of SMT assemblies. Additionally, advancements in processes like solder paste application and inspection techniques will improve the quality and yield of SMT production, reducing defects and enhancing overall efficiency.

Automation and Smart Manufacturing

The integration of automation in SMT production lines is set to increase. Smart factories utilizing robotics, artificial intelligence, and machine learning will optimize production processes, allowing for real-time monitoring, predictive maintenance, and enhanced flexibility in manufacturing. This shift will lead to reduced labor costs and improved production timelines.

Sustainability and Eco-Friendly Practices

As environmental concerns grow, the electronics industry is increasingly focused on sustainability. Future SMT processes will likely incorporate eco-friendly materials, reduce waste, and improve energy efficiency. The adoption of lead-free solder and recyclable materials will become more prevalent, aligning with global sustainability goals.

Integration with Emerging Technologies

SMT will increasingly integrate with emerging technologies such as 5G, IoT, and advanced sensor systems. This integration will require SMT solutions that can handle higher frequencies and provide improved performance in terms of signal integrity and thermal management.

Enhanced Testing and Quality Assurance

As SMT components become more complex, the need for advanced testing and quality assurance methods will grow. Future developments may include more sophisticated inspection technologies, such as automated optical inspection (AOI) and X-ray inspection, to ensure the reliability and functionality of SMT assemblies.

Customization and Flexibility

The demand for customized electronics is on the rise. Future Surface Mount Technology processes will need to adapt to smaller production runs and greater variability in designs. This shift will require flexible manufacturing solutions that can accommodate rapid changes in product specifications.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=99662691

Opportunities in the Future of Surface Mount Technology (SMT)

As Surface Mount Technology (SMT) continues to evolve, several opportunities arise for manufacturers, suppliers, and innovators in the electronics industry. Here are some key opportunities to consider:

1. Growth in Consumer Electronics

The demand for consumer electronics, such as smartphones, wearables, and smart home devices, is on the rise. SMT’s ability to facilitate miniaturization and efficiency makes it a critical technology for these products. Manufacturers can capitalize on this growth by developing specialized SMT solutions tailored to consumer electronics.

2. Expansion of the IoT Market

The Internet of Things (IoT) is expanding rapidly, creating a need for more compact, efficient, and interconnected devices. SMT plays a vital role in enabling the production of IoT devices, providing opportunities for companies to innovate in sensor technology, connectivity, and energy efficiency.

3. Advancements in Electric Vehicles (EVs)

The automotive industry is undergoing a significant transformation with the rise of electric vehicles and advanced driver-assistance systems (ADAS). SMT offers the potential to reduce the size and weight of electronic components in EVs, leading to opportunities for manufacturers to supply SMT solutions for this growing market.

4. Smart Manufacturing and Industry 4.0

The shift toward smart manufacturing presents an opportunity for SMT providers to integrate their technologies with automation and digital solutions. Embracing Industry 4.0 principles allows manufacturers to improve production efficiency, reduce costs, and enhance flexibility through data-driven decision-making.

5. Emerging Markets and Global Expansion

As emerging markets continue to grow, there is an increasing demand for electronics in sectors like telecommunications, healthcare, and industrial automation. Companies that invest in SMT capabilities can establish a presence in these markets and cater to the rising need for advanced electronic products.

6. Focus on Sustainability

With an increasing emphasis on sustainability, there are opportunities for SMT manufacturers to develop eco-friendly materials and processes. Innovations in lead-free solder, recyclable components, and waste reduction strategies can position companies as leaders in sustainable electronics manufacturing.

7. Customization and Niche Markets

The growing demand for customized electronic solutions opens avenues for SMT industry providers to specialize in niche markets. Companies that offer tailored SMT solutions for specific applications—such as medical devices, aerospace, or defense—can differentiate themselves and capture market share.

8. Partnerships and Collaborations

Opportunities for collaboration between SMT manufacturers, technology providers, and research institutions can lead to innovative solutions and shared resources. Strategic partnerships can enhance R&D efforts and bring new products to market more efficiently.

Surface Mount Technology is rich with opportunities driven by advancements in consumer electronics, IoT, automotive applications, and sustainability. By embracing these opportunities and adapting to market demands, companies in the SMT space can position themselves for growth and success in an increasingly competitive landscape.

The future of Surface Mount Technology is bright, characterized by innovations that will enhance efficiency, reliability, and sustainability in electronics manufacturing. As industries continue to evolve, SMT will remain at the forefront, adapting to meet the challenges and opportunities presented by new technologies and consumer demands. Embracing these advancements will be essential for manufacturers aiming to stay competitive in the dynamic landscape of electronics.

The report profiles key players in the surface mount technology (SMT) companies and analyzes their market shares.

- Fuji Corporation (Japan),

- Mycronic AB (Sweden),

- Nordson Corporation (US),

- Viscom AG (Germany),

- KLA Corporation (US),

- Juki Corporation (Japan),

- Hitachi High-Technologies Corporation (Japan),

- ASM Assembly Systems (Germany),

- Yamaha Motor (Japan), and

- Saki Corporation (Japan) are some major players.

Frequently Asked Question

- What are the key trends influencing the future of SMT?

Key trends include miniaturization of components, advancements in automation and smart manufacturing, the rise of IoT and electric vehicles, and increased emphasis on sustainability. - How is SMT contributing to the development of IoT devices?

SMT enables the production of smaller and more compact components, which is essential for IoT devices that require efficient use of space while maintaining functionality and connectivity. - What are the sustainability practices being adopted in SMT?

Manufacturers are focusing on using eco-friendly materials, developing lead-free solder, and implementing waste reduction strategies to enhance the sustainability of SMT processes. - How will Industry 4.0 affect the SMT market?

Industry 4.0 will bring advanced automation, data analytics, and smart manufacturing practices to SMT, improving efficiency, reducing costs, and enhancing product quality through real-time monitoring and predictive maintenance.

About MarketsandMarkets™

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ’GIVE Growth’ principle, we work with several Forbes Global 2000 B2B companies – helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103

Delray Beach, FL 33445

USA : 1-888-600-6441