The Non-Destructive Testing (NDT) and Inspection market Ecosystem is essential for industries that require high standards of quality and safety, such as aerospace, automotive, construction, energy, and manufacturing. NDT and inspection technologies allow businesses to assess the integrity and functionality of their products, equipment, and infrastructure without causing damage, ensuring safety, reducing downtime, and extending product life cycles. With the growing complexity of industrial operations and the need for more precise, reliable, and efficient inspection processes, the global NDT and inspection market has become a critical segment within the broader industrial ecosystem.

As industries evolve with cutting-edge technologies like automation, robotics, and artificial intelligence, the NDT and inspection landscape is also undergoing significant transformations. Explore the global NDT and inspection market ecosystem, key market drivers, trends, challenges, and opportunities that shape its growth and future trajectory.

What is Non-Destructive Testing (NDT)?

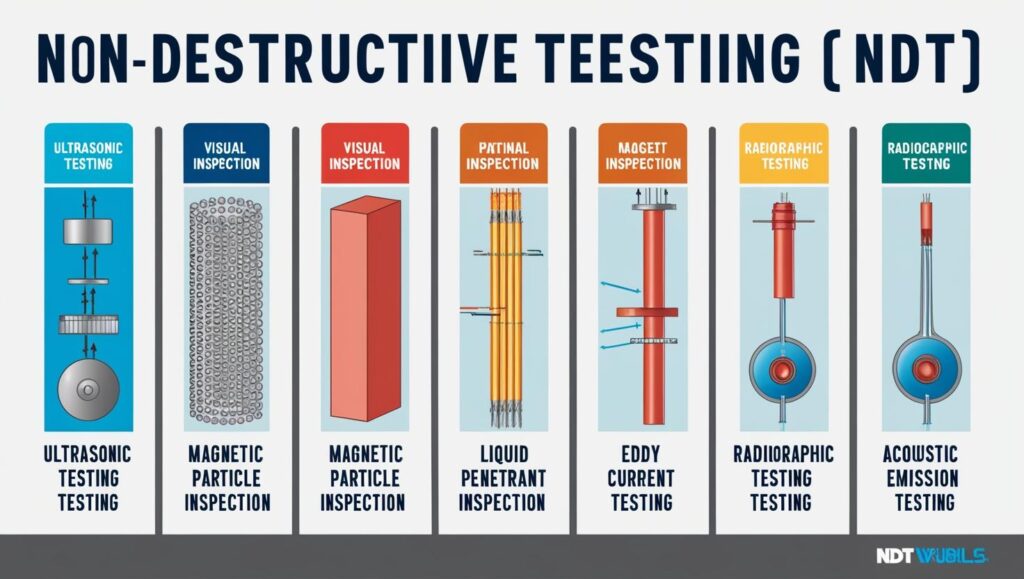

Non-Destructive Testing (NDT) refers to the practice of evaluating the properties of materials, components, or systems without causing any damage to them. NDT methods are employed to detect flaws, cracks, and other potential issues early in the process, which helps avoid costly repairs, improve safety standards, and prevent equipment failure. Common

NDT methods include:

Ultrasonic Testing (UT)

Magnetic Particle Testing (MPT)

Radiographic Testing (RT)

Eddy Current Testing (ECT)

Visual Inspection (VT)

Dye Penetrant Testing (DPT)

Inspection, on the other hand, refers to the visual and mechanical evaluation of components or systems to ensure they meet specific criteria for quality, safety, and performance. While NDT is often a part of the inspection process, it is the broader concept of inspection that encompasses a wide range of techniques and procedures.

The NDT and inspection industry is expected to reach USD 18.4 billion by 2029 from 11.6 billion in 2024, at a CAGR of 9.6% during the 2024-2029 period. Various companies are investing in NDT and Inspection which gives an opportunity for growth in the NDT and Inspection industry . The NDT and Inspection industry is continuously developing, with the presence of multiple players. North America is likely to contribute significantly to the growth of the NDT and Inspection industry . Similarly, the Asia Pacific, Europe, and RoW regions are expected to be the growing market for the forecasted period.

Key Drivers of the Global NDT and Inspection Market

The NDT and inspection market ecosystem is experiencing rapid growth, driven by several key factors:

1. Growing Demand for Safety and Quality Assurance

Industries such as aerospace, automotive, energy, and construction are increasingly emphasizing safety and quality assurance to prevent accidents and improve operational efficiency. The global rise in safety regulations and standards across various industries has heightened the demand for reliable NDT and inspection technologies. In sectors like aerospace, for instance, NDT ensures that critical components, such as turbines, engines, and structural parts, maintain integrity and meet stringent safety requirements.

2. Advancements in NDT Technologies

Technological innovations are expanding the capabilities and applications of NDT techniques. Digital radiography, automated ultrasonic testing, and robotic inspection systems are enhancing the efficiency, accuracy, and reach of NDT solutions. The incorporation of artificial intelligence (AI) and machine learning into NDT processes allows for more sophisticated data analysis, enabling predictive maintenance and reducing the risk of human error. These advancements are improving the overall effectiveness and speed of inspection procedures.

3. Industrialization and Infrastructure Development

With global industrialization on the rise, especially in emerging economies, the need for NDT and inspection services is expanding across sectors. The construction of new infrastructure, the maintenance of aging assets, and the development of critical industrial plants all require rigorous inspection to ensure structural integrity, operational safety, and longevity. In sectors such as oil and gas and power generation, the inspection of pipelines, reactors, and other vital systems plays a significant role in preventing catastrophic failures.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=882

4. Regulatory Compliance and Standards

Governments and industry bodies worldwide have established regulations that mandate the use of NDT and inspection technologies. These regulations are designed to safeguard workers, the environment, and products by ensuring that manufacturing processes and infrastructure remain safe and compliant with industry standards. For example, in the aerospace industry, regulatory bodies like the FAA (Federal Aviation Administration) in the U.S. and the EASA (European Union Aviation Safety Agency) in Europe have stringent requirements for NDT to maintain airworthiness and safety.

5. Increasing Focus on Preventive Maintenance

In industries with complex machinery and critical infrastructure, predictive maintenance is becoming a key focus. Predictive maintenance aims to foresee potential failures before they happen and reduce unplanned downtime. NDT plays a crucial role in this strategy by detecting early-stage faults that may otherwise go unnoticed until they cause significant damage. As industries continue to adopt Industry 4.0 and smart manufacturing practices, the integration of real-time data analysis from NDT equipment into broader maintenance and monitoring systems is improving operational efficiency.

Market Trends and Innovations

The global NDT and inspection market is evolving with several key trends and innovations that promise to shape its future:

1. Integration of AI and Machine Learning

Artificial intelligence and machine learning algorithms are increasingly being integrated into NDT systems. These technologies can analyze vast amounts of data collected during inspections, identify patterns, and offer real-time insights that assist in decision-making. AI can be used to automate the analysis of complex NDT results, reducing human error and improving the precision of inspections.

For instance, AI-powered image recognition and deep learning can be employed to identify defects or anomalies in materials during visual inspections or radiographic testing. This advancement significantly enhances efficiency and accuracy in detecting flaws, especially in large, complex systems.

2. Robotics and Automation in Inspection

Robots equipped with NDT sensors are revolutionizing inspection procedures, particularly in hazardous or hard-to-reach environments. The use of drones for aerial inspections, particularly in the energy and infrastructure sectors, has gained popularity for inspecting powerlines, wind turbines, pipelines, and towers. Similarly, automated robotic inspection systems are increasingly employed in industries like automotive manufacturing, where they can inspect parts at high speeds without human intervention.

3. Remote and In-Situ Inspection Solutions

With industries moving toward digitalization, remote inspection solutions are becoming increasingly common. Using IoT-connected devices, cloud computing, and augmented reality (AR), NDT professionals can now conduct inspections remotely, often in real time. This trend is particularly beneficial in industries like oil and gas, where inspecting offshore platforms and deep-sea equipment can be risky and costly. Remote inspection technologies allow inspectors to monitor and analyze equipment conditions from a safe distance.

4. Growing Adoption of Digital Twin Technology

The rise of digital twin technology—creating a virtual replica of physical assets—is gaining traction in the NDT and inspection market. By integrating NDT inspection data into digital twins, companies can simulate the condition of assets in real-time, enabling predictive maintenance and optimization of operational performance. This development helps industries such as energy and manufacturing to maximize asset life and improve productivity.

Challenges and Opportunities

Despite the growth prospects, the NDT and inspection market faces several challenges:

High Initial Costs: Implementing advanced NDT systems, especially those that incorporate AI, robotics, and automation, can be expensive for small and medium-sized enterprises (SMEs).

Skilled Workforce Shortage: As inspection technologies become more sophisticated, there is a growing demand for highly skilled technicians and engineers who can operate and analyze advanced NDT systems.

Standardization: The lack of universally accepted standards for NDT technologies, especially in emerging markets, can hinder the widespread adoption of advanced inspection methods.

However, these challenges also present opportunities for innovation and growth in the NDT and inspection market. Companies that develop cost-effective solutions, invest in workforce training, and push for greater standardization will be well-positioned to lead the market.

The global NDT and inspection companies is on a path of significant growth, driven by the increasing demand for safety, quality assurance, and efficient operational practices across industries. Technological advancements in AI, robotics, remote inspection, and predictive maintenance are opening up new avenues for inspection providers and manufacturers alike. While challenges remain, the future of the NDT and inspection ecosystem looks promising, with substantial opportunities for businesses to innovate and enhance their operations.

As industries continue to evolve, the integration of cutting-edge inspection technologies will not only improve safety and operational performance but will also play a pivotal role in driving global sustainability initiatives and ensuring the longevity of critical infrastructure and assets.

Top NDT and Inspection companies include:

- General Electric (US)

- MISTRAS Group (US)

- Olympus Corporation (Japan)

- Ashtead Technology (Scotland)

- Nikon Metrology NV (UK)

- SGS Société Générale De Surveillance SA, (Switzerland)

- Magnaflux (US)

- Eddyfi Technologies (Canada)

- Sonatest (UK)

- Intertek Group plc (UK)

- Applus+ (Spain)

- Bureau Veritas (France)

- Comet Group (Switzerland)

- TUV Rheinland (Germany)

- FISCHER TECHNOLOGY INC. (US)

- Acuren (US)

- CREAFORM (Canada)

- Vidisco Ltd. (Israel)

- DEKRA (Germany)

- Team, Inc. (US)

- Labquip NDT (US)

- Cygnus Instruments Ltd. (UK)

- FPrimeC Solutions Inc. (Canada)

- Carestream Health (US)

- Element Materials Technology (UK)

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America’s Best Management Consulting Firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. With the widest lens on emerging technologies, we are proficient in co-creating supernormal growth for clients across the globe.

Today, 80% of Fortune 2000 companies rely on MarketsandMarkets, and 90 of the top 100 companies in each sector trust us to accelerate their revenue growth. With a global clientele of over 13,000 organizations, we help businesses thrive in a disruptive ecosystem.

The B2B economy is witnessing the emergence of $25 trillion in new revenue streams that are replacing existing ones within this decade. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ‘GIVE Growth’ principle, we collaborate with several Forbes Global 2000 B2B companies to keep them future-ready. Our insights and strategies are powered by industry experts, cutting-edge AI, and our Market Intelligence Cloud, KnowledgeStore™, which integrates research and provides ecosystem-wide visibility into revenue shifts.

In addition, MarketsandMarkets SalesIQ enables sales teams to identify high-priority accounts and uncover hidden opportunities, helping them build more pipeline and win more deals with precision.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter , LinkedIn and Facebook .

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103, Delray Beach, FL 33445

USA: +1-888-600-6441

Visit Our Website: https://www.marketsandmarkets.com/