A majority of consumers around the world have become more inclined toward food products that offer additional health benefits and are easy to prepare. Several food manufacturers are developing a variety of functional food & beverage products in order to fulfill the growing demand for value-added food. Owing to the increase in the number of functional food consumers, food product and ingredient manufacturers have increased their investment in spray drying technologies, for optimum supply of these particular food products to end consumers. Spray dryers are being significantly utilized in the processing of fruits & vegetable powders, dietary fibers, and prebiotic foods, due to the efficiency offered by them in terms of quality and shelf life of the final product. The global spray drying equipment market is projected to reach USD 6.12 billion by 2023, at a CAGR of 6.94% from 2017.

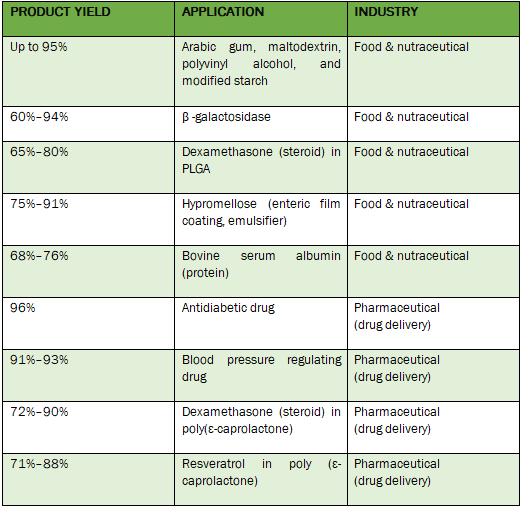

Product Yield Optimization Achieved by Spray Drying

The high product yield offered by spray drying is one of the important advantages that is anticipated to drive the growth of the global spray drying equipment market in the coming years. With the help of advanced spray drying equipment such as nanospray dryers, product yield can be optimized up to 60%–96%, depending on the application. Therefore, the demand for spray drying equipment is increasing for several product development activities and applications in the food and pharmaceutical industries. For instance, Patheon (Netherlands) which is one of the prominent suppliers of high-quality drug development and delivery solutions to the pharmaceutical sector invested approximately USD 45 million in spray drying & manufacturing solutions across its key sites around the world.

Optimized Product Yield Obtained From Nanospray Drying

Source: NTB University of Applied Sciences of Technology Buchs; Institute for Energy Systems, Buchs, Switzerland; BÜCHI Labortechnik AG, Flawil, Switzerland

Download PDF Brochure@ https://www.marketsandmarkets.com/pdfdownload.asp?id=229851536

Nanospray drying equipment is highly demanded owing to its advantages such as ease of use, energy efficiency, and low operating cost. Moreover, consistent product development activities and the launch of advanced nanospray drying equipment by key market players have also been driving the growth of the spray drying equipment market over the past few years. For instance, in February 2017, BÜCHI Labortechnik AG (Switzerland) introduced Nano Spray Dryer B-90 HP, a high performing product that is ideal for various applications in the pharmaceutical industry.

Technological Innovations and Advancements in Spray Drying Equipment

The usage of spray dryers for nanoencapsulation in food and nutraceutical applications and for bioceramics in bone tissue & dental cement applications has played an important role in the growth of the spray drying market in recent years.

In addition, Labplant (UK) is currently developing a spray dryer that is integrated with a camera, color screen, and other devices such as an iPad. This product offers customers better control over the spray drying unit, and thereby, effective output. Labplant is planning to launch this product by mid-2019.

Growth Opportunities in Bioceramics and Biotechnology

Emerging applications in bioceramics and biodegradable polymer industries, as a result of constant innovations in the field of spray drying, are expected to create potential opportunities for global spray drying players in coming years. According to a case study published by BÜCHI Labortechnik AG (Switzerland), “a researcher successfully utilized the BUCHI Mini Spray Dryer B-290 for hydroxyapatite and bioglass ceramics that are utilized as renewable materials in bone and teeth. This spray dryer effectively adjusted the shape and particle size of ceramic materials which aided in fulfilling the customer’s requirements.”