The integration of Artificial Intelligence (AI) into various industries has brought about significant transformations, and the piezoelectric devices market is no exception. Piezoelectric devices, which convert mechanical energy into electrical energy and vice versa, are pivotal components in a wide range of applications, including healthcare, automotive, consumer electronics, and industrial sectors. When AI is incorporated into piezoelectric technology, it drives enhanced precision, efficiency, and sustainability, unlocking new potential for innovation and improving product performance across industries.

Explore how AI is revolutionizing the piezoelectric devices market, its impact on performance optimization, and the role it plays in pushing the boundaries of technology toward more sustainable solutions.

The global piezoelectric devices market size is expected to grow from USD 35.59 billion in 2024 to USD 55.49 billion by 2030 at a CAGR of 7.7% during the estimated period 2024-2030.

1. Understanding Piezoelectric Devices

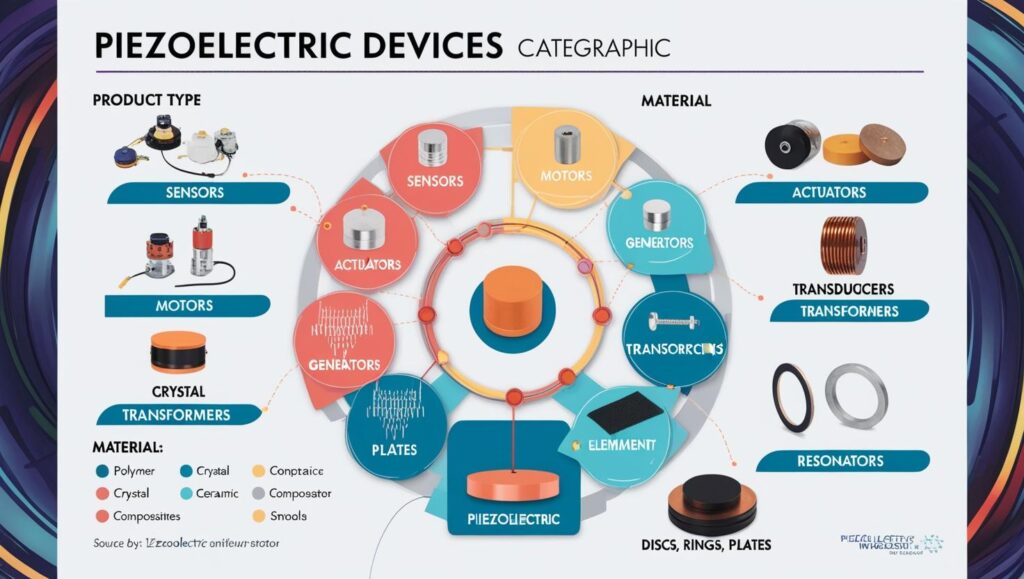

Piezoelectric devices work based on the principle of the piezoelectric effect, where certain materials generate an electric charge when subjected to mechanical stress. These devices are commonly used in sensors, actuators, and energy harvesters. They are essential in applications such as:

Medical devices like ultrasound machines

Vibration sensors in machinery

Smartphones for touch-sensitive screens

Automotive sensors for collision detection and energy recovery

Piezoelectric devices have been widely used for decades, but with the advent of AI and machine learning (ML) technologies, these devices are now experiencing improvements in functionality, efficiency, and adaptability.

2. Precision and Accuracy Boost with AI

One of the most important areas where AI is making an impact in piezoelectric devices is in precision. Many piezoelectric devices rely on real-time data to function optimally, whether in sensors for monitoring vibrations in industrial machinery or in actuators for controlling movements in robotic systems. AI allows for more accurate data processing, predictive maintenance, and decision-making that enhance the precision of these devices.

AI-powered algorithms enable piezoelectric systems to adapt and fine-tune their responses based on real-time inputs, ensuring that they provide accurate measurements, feedback, and actions with minimal error. For instance:

In medical applications, AI can improve the accuracy of ultrasound imaging by processing piezoelectric sensor data more effectively, leading to better diagnostics and more precise imaging.

In industrial applications, AI can optimize the functionality of vibration sensors by predicting equipment failures before they occur, preventing costly downtimes and improving overall precision in machinery.

3. Enhancing Efficiency in Piezoelectric Devices

Efficiency is crucial in industries that rely on piezoelectric devices, and the integration of AI is delivering substantial improvements. By using machine learning models and data analytics, AI can enhance the performance of piezoelectric systems in the following ways:

Energy Harvesting: AI can optimize the energy conversion efficiency of piezoelectric devices, especially in energy harvesting applications. By analyzing the patterns of vibrations or mechanical forces, AI can predict the optimal times for energy harvesting and adjust the piezoelectric system’s operation to maximize energy generation.

Predictive Maintenance: In industrial machinery, piezoelectric sensors are often used to detect vibrations, strain, or temperature changes, which can be indicative of potential mechanical issues. AI-driven analytics allow for predictive maintenance, enabling systems to identify potential problems before they result in equipment failure. This reduces downtime and improves the operational efficiency of machines.

Smart Controls in Actuators: AI can enhance the performance of piezoelectric actuators by controlling their movements more efficiently. Whether used in robotics or precision manufacturing, AI algorithms help fine-tune actuator behaviors, resulting in improved productivity and energy savings.

Download PDF Brochure @

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=256019882

4. Advancing Sustainability through AI in Piezoelectric Devices

As industries around the world strive to become more sustainable, AI is playing a crucial role in making piezoelectric devices greener and more eco-friendly. Here are some of the ways AI contributes to sustainability in the piezoelectric devices market:

Energy Efficiency: By optimizing the operation of piezoelectric energy harvesters, AI ensures that these devices generate electricity more efficiently, reducing the reliance on traditional power sources and minimizing energy waste. This is particularly important in applications such as wearable electronics or remote sensors, where low-energy solutions are essential.

Material Optimization: AI can also aid in the development of new piezoelectric materials with higher energy conversion efficiency, leading to devices that use less energy and require fewer resources to produce. By using AI in the materials discovery process, manufacturers can develop sustainable piezoelectric materials with reduced environmental impacts.

Reducing Environmental Footprint: AI-driven predictive maintenance allows piezoelectric systems to function at optimal levels, thereby extending their lifespan and reducing waste. By ensuring that devices operate efficiently and are maintained properly, AI helps reduce the need for replacements and decreases the environmental impact of the devices.

5. Key Industry Sectors Impacted by AI in Piezoelectric Devices

The integration of AI in piezoelectric devices has profound implications for various industries, including:

a. Healthcare

AI is improving piezoelectric devices in the healthcare industry, particularly in the area of ultrasonic imaging. AI algorithms can enhance image quality, optimize signal processing, and improve diagnostic accuracy. Additionally, AI-driven piezoelectric sensors are being used for non-invasive monitoring of vital signs and in wearable health devices that detect changes in blood pressure, heart rate, and other health indicators.

b. Automotive

In the automotive sector, AI-enhanced piezoelectric sensors are used for active safety features like collision detection and vibration monitoring in vehicles. By incorporating machine learning into these sensors, automakers can improve the accuracy and response time of safety systems, making vehicles smarter and more reliable.

c. Manufacturing and Industrial Automation

AI-driven piezoelectric sensors are revolutionizing predictive maintenance and quality control in manufacturing. With AI-powered analytics, piezoelectric devices can monitor machines in real time, detecting any signs of failure before they lead to significant damage. This predictive approach improves overall productivity and operational efficiency.

d. Consumer Electronics

AI-enabled piezoelectric devices are enhancing the functionality of touch screens, microphones, and speakers in consumer electronics. AI helps these devices become more responsive, energy-efficient, and adaptive to user needs, improving the overall experience for consumers.

6. The Future Outlook for AI in Piezoelectric Devices

As AI continues to advance, the potential applications in piezoelectric devices will expand even further. The future of the market holds several exciting developments:

Smart Devices: The rise of smart wearables and IoT devices will drive the demand for AI-powered piezoelectric sensors that can optimize energy usage, detect physical activity, and enhance overall performance.

Enhanced Customization: AI will allow for more customized piezoelectric devices tailored to specific industry needs, from healthcare to manufacturing, with a focus on improving performance and reducing costs.

Next-Generation Materials: Ongoing AI research in materials science will lead to the development of new piezoelectric materials that are more efficient, durable, and sustainable.

The integration of AI in piezoelectric devices is driving unprecedented improvements in precision, efficiency, and sustainability across multiple industries. With AI algorithms optimizing energy harvesting, enhancing actuator control, improving accuracy in sensors, and enabling predictive maintenance, piezoelectric devices are becoming more powerful and effective. As AI technology continues to evolve, the piezoelectric devices market is poised for even greater innovations, offering smarter, more efficient solutions for industries and contributing to a more sustainable future.

The major piezoelectric devices companies with a significant global presence are

- CeramTec GmbH (Germany),

- CTS Corporation (US),

- Kistler Group (Switzerland),

- Physik Instrumente (PI) SE & Co. KG. (US),

- Aerotech (US),

- Piezosystem jena (Germany),

- KEMET Corporation (US),

- Piezo Technologies (US),

- APC International, Ltd. (US),

- Mad City Labs, Inc (US),

- TE Connectivity (Switzerland),

- Mide Technology Corp (US),

- Omega Piezo Technologies (US) ,

- PCB Piezotronics, Inc. (US), and PiezoMotor (Sweden).

FAQ: AI in Piezoelectric Devices Market

1. What are piezoelectric devices?

Piezoelectric devices are components that generate an electrical charge when subjected to mechanical stress. They are commonly used in sensors, actuators, and energy harvesters. These devices are widely applied in industries such as healthcare, automotive, aerospace, and consumer electronics.

2. How does AI impact the performance of piezoelectric devices?

AI enhances the performance of piezoelectric devices by improving precision, efficiency, and sustainability. AI algorithms process real-time data more accurately, optimize energy conversion, enable predictive maintenance, and adapt the system’s behavior based on environmental factors, ensuring that piezoelectric devices operate at their best.

3. What are some key applications of AI in piezoelectric devices?

AI in piezoelectric devices is used in various applications, including:

- Healthcare: Enhancing ultrasound imaging and health monitoring devices.

- Automotive: Improving safety features like collision detection and vibration monitoring.

- Manufacturing: Optimizing predictive maintenance and quality control.

- Consumer Electronics: Enhancing touch-sensitive screens and speakers.

- Energy Harvesting: Increasing efficiency in converting mechanical energy into electrical power.

4. How does AI improve energy efficiency in piezoelectric devices?

AI improves energy efficiency by optimizing when and how energy is harvested or consumed. In energy harvesting applications, AI predicts the best times for energy collection based on environmental factors such as vibrations or movements. This ensures that piezoelectric devices operate efficiently, reducing waste and extending battery life.

5. How does AI contribute to sustainability in the piezoelectric devices market?

AI contributes to sustainability by improving energy efficiency, reducing material waste, and extending the lifespan of devices through predictive maintenance. It helps optimize the use of piezoelectric devices, reducing the need for replacements and lowering the overall environmental impact of manufacturing and usage.

6. What challenges are faced when integrating AI with piezoelectric devices?

Challenges include the complexity of AI algorithms, data privacy concerns, and the need for high-quality, real-time data to make accurate predictions. Additionally, integrating AI with existing piezoelectric systems may require significant infrastructure upgrades and technical expertise.