In recent years, the Asia Pacific Industrial Control & Factory Automation market has emerged as a significant force, driving transformative changes in manufacturing processes and operations. With advancements in digital technology, automation, and Industry 4.0, the region is rapidly evolving into a global hub for intelligent manufacturing systems. The integration of Industrial Control Systems (ICS) and Factory Automation (FA) is shaping the future of production across multiple sectors, including automotive, electronics, food and beverage, pharmaceuticals, and consumer goods.

This market growth is not just a trend but a fundamental shift in how industries operate, optimize, and innovate. As Asia Pacific becomes the center of global manufacturing, the region is leading the way toward smart factories and intelligent supply chains, supported by cutting-edge technologies like IoT (Internet of Things), AI (Artificial Intelligence), robotics, and machine learning. Let’s explore how the industrial control and factory automation market is evolving in Asia Pacific and its role in the future of smart manufacturing.

The Rise of Industrial Control & Factory Automation

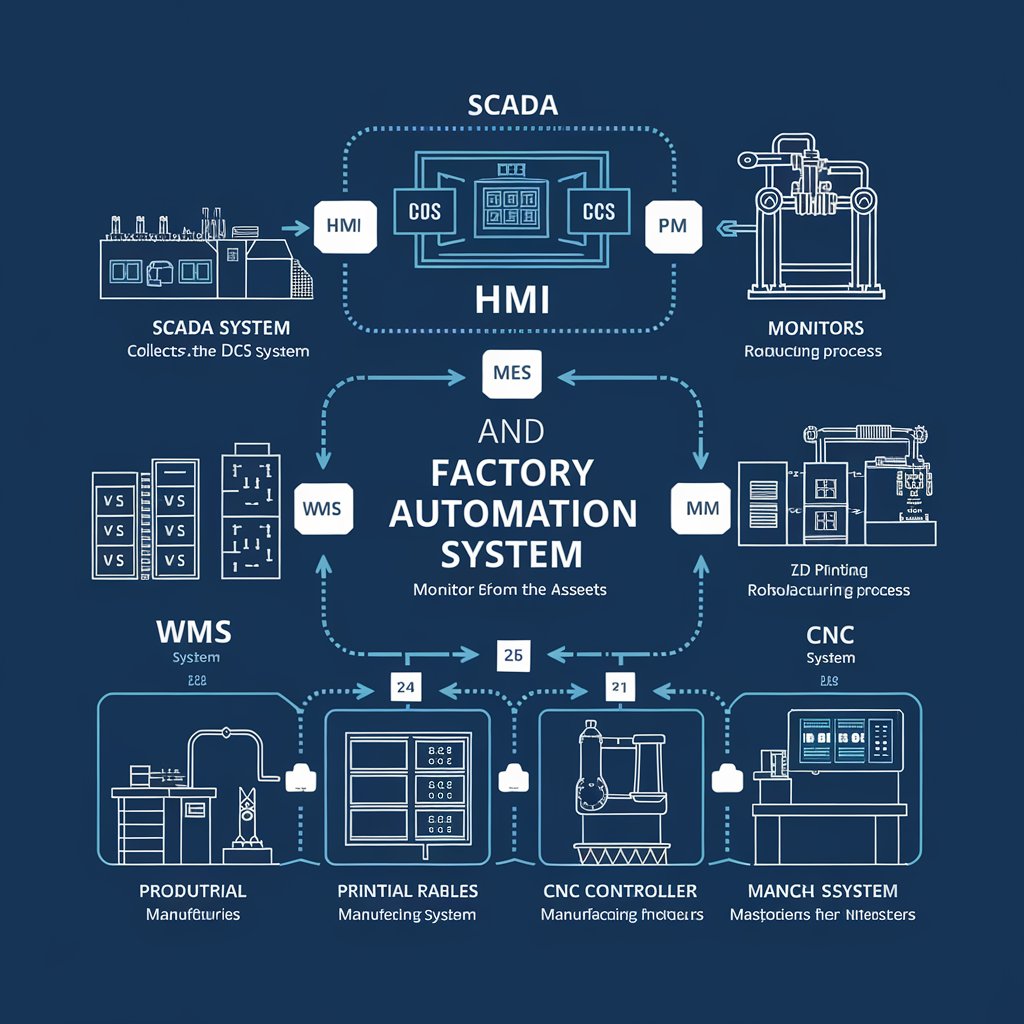

Industrial control systems (ICS) have long been the backbone of manufacturing industries. These systems manage and control machinery and equipment, ensuring that manufacturing processes run smoothly, efficiently, and safely. With the advent of factory automation, the sector has entered a new era of precision, flexibility, and connectivity.

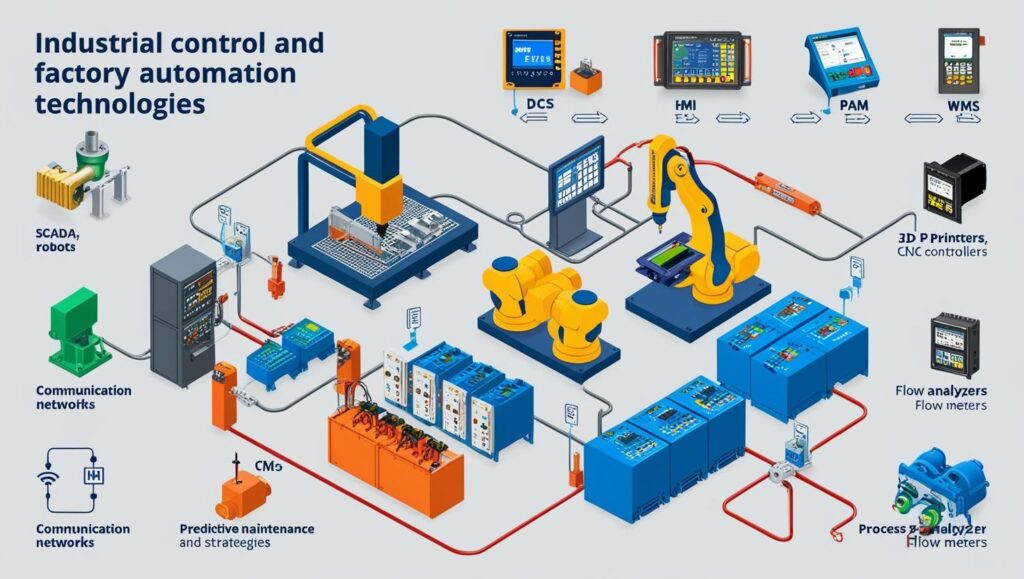

Factory Automation involves the use of control systems such as programmable logic controllers (PLCs), distributed control systems (DCS), and supervisory control and data acquisition (SCADA) systems to automate complex industrial processes. When combined with robotics, IoT-enabled sensors, and AI-powered analytics, factory automation allows businesses to reduce human intervention, increase productivity, and streamline operations.

The Asia Pacific market, characterized by its large manufacturing base and growing demand for innovative technologies, is embracing these advancements at a rapid pace. This is evident in sectors like automotive, electronics, and consumer goods, where the demand for smarter, more efficient production processes is at an all-time high.

Key Drivers of Growth in Asia Pacific’s Industrial Control & Factory Automation Market

Several factors are contributing to the robust growth of the industrial control and factory automation market in Asia Pacific:

1. Industry 4.0 Adoption

The fourth industrial revolution—Industry 4.0—is transforming the manufacturing landscape in Asia Pacific. Industry 4.0 emphasizes the integration of cyber-physical systems, IoT, and artificial intelligence into the production process, enabling machines to communicate, learn, and adapt in real-time. This shift is pushing the adoption of industrial control systems (ICS) and automation technologies as companies seek to enhance operational efficiency, improve product quality, and reduce downtime.

In particular, countries like China, Japan, South Korea, and India are investing heavily in smart factories, which leverage advanced automation and intelligent systems for optimized production. The transition to Industry 4.0 requires cutting-edge control systems to manage increasingly complex processes, making the demand for factory automation solutions skyrocket.

2. Rising Labor Costs and Shortage of Skilled Labor

Labor shortages and rising wages in Asia Pacific are compelling manufacturers to invest in automation. The region has historically relied on low-cost labor to fuel manufacturing growth, but the growing need for skilled workers, coupled with increasing labor costs, has made automation a more attractive solution.

Automating repetitive and labor-intensive tasks not only reduces the dependency on manual labor but also ensures consistency, accuracy, and faster production cycles. By implementing factory automation systems, manufacturers can continue to maintain high levels of output while mitigating labor-related challenges.

3. Technological Advancements and Innovation

The development of new technologies in robotics, machine learning, artificial intelligence (AI), and machine vision is driving factory automation forward. These innovations enable factories to become more adaptable, with machines that can learn from data and adjust operations without human intervention.

In addition, IoT-enabled sensors allow manufacturers to gain real-time visibility into their operations, monitor machine performance, and predict potential issues before they result in costly downtime. This enhanced connectivity and data-driven approach enable businesses to optimize production and maintenance schedules, reducing operational costs.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=541

4. Government Initiatives and Support

Governments across Asia Pacific are actively encouraging automation and digital transformation in the manufacturing sector. For example, China’s Made in China 2025 initiative, Japan’s Society 5.0, and India’s Make in India program are all designed to boost innovation, enhance manufacturing capabilities, and encourage the adoption of advanced technologies like factory automation.

These initiatives often come with funding, tax incentives, and support for the development of new smart factory solutions, driving increased investment in automation systems. The government support in these countries is propelling the expansion of industrial control and factory automation solutions in Asia Pacific.

5. Rising Demand for Customization and Flexibility

As global consumers demand more personalized products and shorter delivery times, manufacturers must adopt more flexible production systems. Factory automation technologies enable mass customization, allowing manufacturers to switch between product variants with minimal downtime.

Through automation, manufacturers can adjust production lines more quickly, optimize resource usage, and improve supply chain management, all while ensuring high-quality outputs. These advancements enable companies to meet the growing demand for customized products in various industries, including automotive, electronics, and consumer goods.

Key Applications of Industrial Control & Factory Automation in Asia Pacific

The Asia Pacific industrial control and factory automation market has vast applications across various sectors. Here are some key industries benefiting from these technologies:

1. Automotive Manufacturing

The automotive sector has been a pioneer in adopting factory automation systems. Automated production lines, robotics, and AI-based systems are used to assemble vehicles with high precision and efficiency. Automation ensures consistent quality, reduces manual labor, and improves safety in the manufacturing process.

Furthermore, the use of industrial control systems (ICS) and automation in the automotive industry allows for optimized inventory management, just-in-time manufacturing, and enhanced supply chain visibility. As electric vehicle (EV) manufacturing gains momentum, automation will continue to play a crucial role in meeting the demand for environmentally-friendly and innovative vehicles.

2. Electronics and Semiconductor Manufacturing

Asia Pacific is home to some of the world’s largest electronics and semiconductor manufacturers, particularly in countries like China, South Korea, and Taiwan. In these industries, factory automation is critical for producing highly complex and precise products, such as smartphones, integrated circuits, and consumer electronics.

Industrial control and automation technologies are used to monitor processes, ensure product quality, and improve yield rates in semiconductor fabrication plants. Robotics and automated material handling systems are also widely used in electronics manufacturing to streamline production and reduce human error.

3. Food and Beverage Industry

The food and beverage industry is increasingly relying on factory automation to improve operational efficiency and maintain food safety standards. Automation is used in processing, packaging, labeling, and quality control. Real-time monitoring through sensors and automation systems ensures that the production process meets regulatory requirements and is free from contamination.

In addition, advanced robotics is helping food manufacturers automate the packaging process, ensuring faster production and reduced human exposure to hazardous materials.

4. Pharmaceuticals and Life Sciences

The pharmaceutical industry is highly regulated and requires precise control over production processes. Automation systems are used to monitor and control manufacturing conditions, track batch production, and ensure compliance with industry regulations. Industrial control systems (ICS) in pharmaceutical manufacturing help manage production lines, reduce human error, and optimize inventory control.

Moreover, factory automation enables track-and-trace systems that allow for real-time monitoring of raw materials, ingredients, and finished products, ensuring product quality and safety.

5. Consumer Goods Manufacturing

The consumer goods industry, particularly in Asia Pacific, is undergoing a transformation, with increasing demand for customizable products. Factory automation systems allow manufacturers to optimize production lines and improve flexibility, enabling them to cater to changing consumer preferences efficiently.

Challenges and Opportunities in the Market

While the Asia Pacific industrial control and factory automation market is expanding rapidly, several challenges remain:

Challenges:

High Initial Investment: The cost of implementing factory automation systems can be high, particularly for small and medium-sized enterprises (SMEs). However, the long-term benefits of increased productivity and reduced operational costs often outweigh the initial investment.

Cybersecurity Risks: As factories become more connected, they are vulnerable to cyber threats. Ensuring the security of industrial control systems and data is essential to protect sensitive information and prevent operational disruptions.

Skilled Workforce Shortage: While automation reduces the reliance on manual labor, there is a growing demand for skilled workers who can manage, maintain, and troubleshoot automated systems. Companies must invest in training and upskilling their workforce to keep up with technological advancements.

Opportunities:

AI and Machine Learning Integration: Integrating AI and machine learning with factory automation systems offers exciting opportunities for predictive maintenance, quality control, and process optimization.

Robotics and Collaborative Robots (Cobots): The rise of collaborative robots, which work alongside human operators, is a game-changer for industries that require both flexibility and precision.

Smart Factory Expansion: As companies continue to embrace Industry 4.0 and smart factory solutions, there are ample opportunities for growth in automation, IoT integration, and data analytics.

The Asia Pacific Industrial Control & Factory Automation Market is transforming the manufacturing sector by driving greater efficiency, precision, and flexibility. As manufacturers seek to remain competitive in an increasingly globalized and technology-driven market, the integration of automation technologies and industrial control systems will continue to play a pivotal role in the region’s manufacturing evolution.

With the ongoing shift toward Industry 4.0, coupled with government support and technological advancements, Asia Pacific is poised to remain a leader in industrial control and factory automation, paving the way for smarter, more efficient manufacturing systems in the future.

About MarketsandMarkets™

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ’GIVE Growth’ principle, we work with several Forbes Global 2000 B2B companies – helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103

Delray Beach, FL 33445

USA : 1-888-600-6441