The Asia Pacific region is rapidly emerging as the heart of innovation in the semiconductor industry, with Extreme Ultraviolet (EUV) lithography technology poised to drive significant breakthroughs in semiconductor fabrication. As the demand for smaller, more powerful chips escalates, EUV lithography is set to revolutionize the way semiconductors are manufactured, and Asia Pacific is positioning itself at the forefront of this transformation.

Explore the pivotal role that EUV lithography is playing in the evolution of semiconductor technology, how Asia Pacific is becoming a key player in the industry, and the expected breakthroughs that will shape the future of advanced chip production.

Understanding EUV Lithography and its Importance in Semiconductor Manufacturing

The EUV lithography market share is expected to reach USD 22.69 billion by 2029 from USD 12.18 billion in 2024, at a CAGR of 13.2% during the 2024-2029 period.

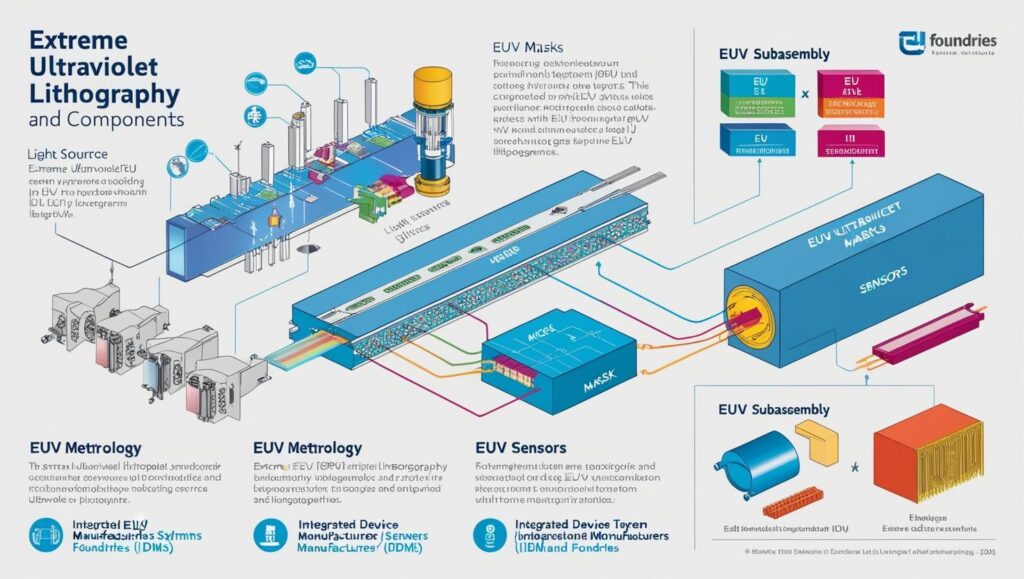

EUV lithography is a cutting-edge technique used in the semiconductor industry to produce chips with smaller nodes—typically in the range of 5nm and beyond. The traditional deep ultraviolet (DUV) lithography used in chip fabrication has reached its physical limits, struggling to create the finer features required for the latest generations of microchips. EUV lithography, with its shorter wavelength of light, enables the creation of smaller and more intricate circuit patterns on semiconductor wafers, allowing for the production of advanced chips that are faster, more power-efficient, and capable of handling increasingly complex computing tasks.

This technological advancement is vital for industries such as artificial intelligence (AI), 5G, automotive electronics, and consumer devices, which all rely on high-performance semiconductors to meet growing computational demands. The ability to produce chips with smaller nodes also directly impacts the ability to pack more transistors onto a chip, thus improving performance and energy efficiency.

Asia Pacific: The Epicenter of EUV Lithography Innovation

Asia Pacific has long been a dominant force in the global semiconductor market, with countries like South Korea, Japan, China, and Taiwan hosting some of the world’s largest semiconductor manufacturers. The region is now emerging as a key player in the development and implementation of EUV lithography, which is set to accelerate the advancement of semiconductor fabrication.

1. Taiwan’s TSMC: Leading the Charge

Taiwan, home to Taiwan Semiconductor Manufacturing Company (TSMC), a world leader in semiconductor manufacturing, is at the center of the EUV revolution. TSMC has been actively investing in EUV lithography to ramp up the production of 5nm and 3nm chips, serving the demand from tech giants like Apple, Qualcomm, and NVIDIA. TSMC’s massive investment in EUV technology has made it one of the first companies to produce chips at these advanced nodes, enabling the development of next-generation devices such as smartphones, high-performance computing systems, and AI-driven technologies.

By leveraging EUV lithography, TSMC is not only pushing the boundaries of chip miniaturization but also gaining a competitive edge in the rapidly evolving semiconductor market. The company’s ability to scale EUV technology efficiently will be pivotal in sustaining its leadership position in the global semiconductor supply chain.

2. South Korea’s Samsung Electronics: Advancing EUV Capabilities

In South Korea, Samsung Electronics is another key player advancing EUV lithography in the semiconductor sector. Samsung has been heavily investing in EUV lithography to produce 7nm and 5nm chips for its Exynos processors, used in smartphones, and for AI applications. The company aims to scale its EUV capabilities to 3nm and beyond, allowing it to cater to the growing demand for high-performance chips across a wide range of sectors, including automotive, smart devices, and data centers.

Samsung’s push for next-generation semiconductor production using EUV lithography positions the company as a direct competitor to TSMC, with both companies vying for the top spot in the cutting-edge foundry business. Samsung’s ability to advance EUV technologies will play a crucial role in the continued development of AI, 5G, and high-performance computing systems.

3. Japan’s Contributions to EUV Development

Japan has also made significant strides in advancing EUV lithography through its expertise in semiconductor materials and equipment manufacturing. Companies like ASML and Canon are collaborating with semiconductor giants across Asia Pacific to develop next-generation EUV equipment and technologies. Japan’s role in supplying essential components for EUV lithography, including light sources, optics, and mask blanks, positions the country as a critical enabler of EUV adoption in the region.

Japan’s focus on improving EUV capabilities through research and development will not only contribute to the growth of the local semiconductor industry but will also bolster the global semiconductor supply chain.

Download PDF Brochure @

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=241564826

4. China’s Efforts to Build EUV Lithography Capabilities

While China has faced challenges in developing its own EUV lithography technology, the country is making significant strides to invest in semiconductor R&D and AI-driven technologies. China’s government has heavily subsidized the local semiconductor industry, with the aim of reducing its dependence on foreign technology providers. As China seeks to increase its self-sufficiency in semiconductor manufacturing, the country’s focus on EUV technology could lead to breakthroughs in domestic semiconductor production.

China’s push for EUV lithography may also influence the global semiconductor market, as the country looks to become a key player in the production of advanced chips for both consumer electronics and industrial applications.

Breakthroughs on the Horizon: The Future of EUV Lithography in Asia Pacific

The impact of EUV lithography in the Asia Pacific region is expected to reach new heights as the technology continues to evolve. Here are some key breakthroughs expected in the coming years:

1. 3nm and Beyond

One of the most significant milestones in EUV lithography is the ability to scale production to 3nm and 2nm nodes. Asia Pacific’s semiconductor giants, including TSMC and Samsung, are already investing in the infrastructure needed to produce these ultra-small chips. These smaller nodes will enable even more powerful and energy-efficient chips, ideal for next-generation applications in AI, quantum computing, and 5G networks.

2. High-Volume Manufacturing (HVM)

The next breakthrough in EUV lithography will be the ability to achieve high-volume manufacturing at advanced nodes. As more companies adopt EUV technology, the cost of EUV systems will decrease, making them more accessible to a broader range of manufacturers. This will increase the scalability of EUV technology and bring down the cost of producing advanced semiconductors, ultimately benefiting industries across the globe.

3. Innovation in EUV Equipment

Research and development in EUV lithography equipment will continue to focus on enhancing the performance and reliability of these systems. Innovations in light sources, optical materials, and mask-making will help drive down production costs while improving the accuracy and yield of semiconductor manufacturing processes.

Asia Pacific is well-positioned to lead the EUV lithography revolution, with countries like Taiwan, South Korea, Japan, and China making significant strides in developing the necessary technologies and infrastructure to support the next generation of semiconductor fabrication. As EUV lithography continues to evolve, breakthroughs in chip production at smaller nodes, high-volume manufacturing, and improved equipment are expected to shape the future of the global semiconductor industry.

With Asia Pacific’s dominance in EUV technology, the region is set to play a pivotal role in enabling the future of computing, fueling advancements in artificial intelligence, 5G networks, autonomous vehicles, and a host of other transformative technologies. As the industry pushes forward, Asia Pacific’s leadership in EUV lithography will be critical in meeting the increasing demand for faster, more efficient, and sustainable semiconductor solutions.

Major Extreme Ultraviolet (EUV) Lithography companies include:

- ASML (Netherlands)

- Carl Zeiss AG (Germany)

- NTT Advanced Technology Corporation (Japan)

- KLA Corporation (US)

- ADVANTEST CORPORATION (Japan)

- Ushio Inc. (Japan)

- SUSS MicroTec SE (Germany)

- AGC Inc. (Japan)

- Lasertec Corporation (Japan)

- TOPPAN Inc. (Japan)

- Energetiq Technology, Inc. (Japan)

- NuFlare Technology Inc. (US)

- Photronics, Inc. (Japan)

- HOYA Corporation (Japan)

- TRUMPF (Germany)

- Rigaku Holdings Corporation (Japan)

- Edmund Optics Inc. (US)

- Imagine Optic (France)

- Applied Materials, Inc. (US)

- Park Systems (South Korea)

- EUV Tech (US)

- Mloptic Corp. (China)

- MKS Instruments (US)

- Brooks Automation (US)

- Pfeiffer Vacuum GmbH (Germany)

FAQ: Asia Pacific’s EUV Lithography Industry

1. What is EUV lithography and why is it important?

Extreme Ultraviolet (EUV) lithography is a cutting-edge technology used in semiconductor manufacturing to produce chips with very small features, typically 5nm or smaller. EUV uses extremely short wavelengths of light (around 13.5nm) to create fine patterns on semiconductor wafers. This is crucial for advancing the miniaturization of chips, which improves their performance, speed, and energy efficiency, essential for modern applications such as AI, 5G, and high-performance computing.

2. Why is the Asia Pacific region leading in EUV lithography technology?

Asia Pacific has become a global hub for semiconductor manufacturing, with key players such as TSMC (Taiwan), Samsung Electronics (South Korea), and ASML (Japan and the Netherlands) heavily investing in EUV technology. The region’s strong semiconductor industry, significant R&D investments, and strategic collaborations have helped it become the leader in developing and deploying EUV lithography technology.

3. Which countries in Asia Pacific are driving EUV lithography advancements?

Taiwan, home to TSMC, is a major leader in EUV adoption, driving the production of advanced chips. South Korea, through Samsung Electronics, is also making significant strides in EUV technology. Japan plays a critical role in developing EUV components like light sources and optics, while China is investing heavily in expanding its semiconductor industry, including EUV capabilities, to reduce reliance on foreign technologies.