New Revenue Pockets:

The global cryogenic equipment market is projected to reach USD 16.6 billion by 2028 from an estimated USD 11.9 billion in 2023, at a CAGR of 6.9% during the forecast period. The global transition to clean energy sources represents a significant driver for the heightened demand for cryogenic equipment.

Key Market Players

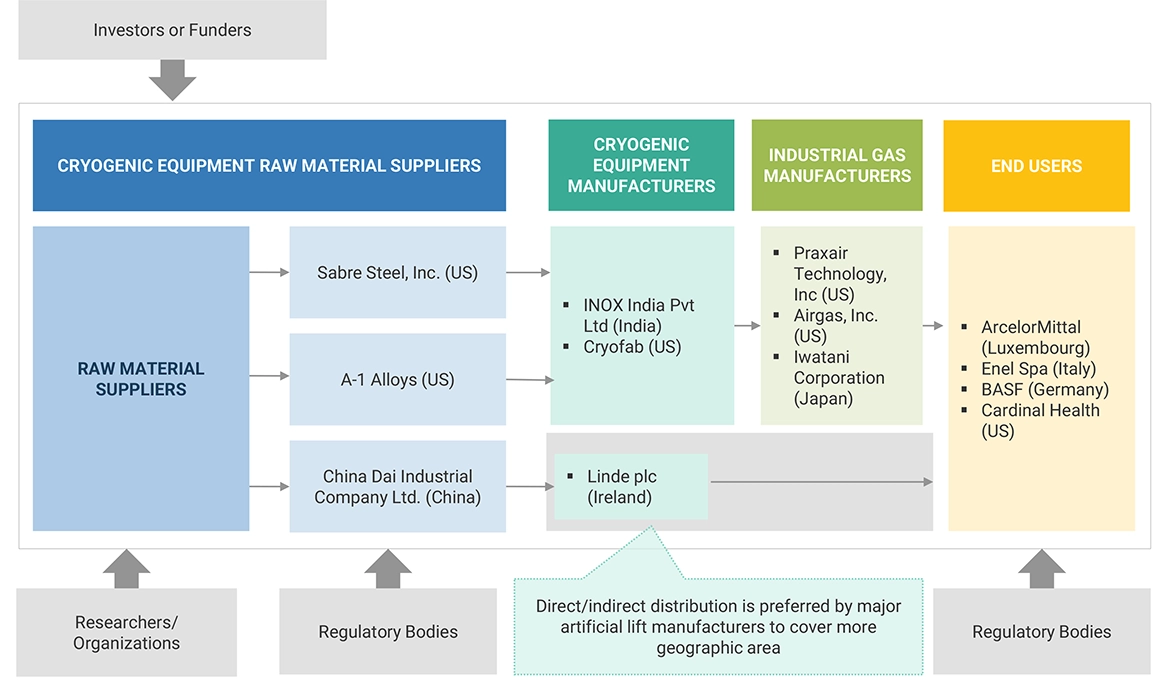

Prominent companies in this market include as Linde plc (Ireland); Air Liquide (France); Air Products and Chemicals, Inc. (US); Chart Industries (US); Parker Hannifin Corp. (US); Flowserve Corporation (US); Nikkiso Co., Ltd. (Japan); and INOX India Limited (India).

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=735

Cryogenic Equipment Market – Restraints, Output and Growth

This report segments the cryogenic equipment market based on equipment into five categories: tanks, valves, vaporizers, pumps and other equipments. Valves are expected to hold the second-largest market share in the cryogenic equipment market during the forecast period. Cryogenic valves are essential for handling liquefied gases, particularly in LNG, LPG, and other cryogenic processes. These valves are vital for maintaining leak-free operations during heating and cooling cycles. There is a variety of cryogenic valve types, including manual and actuated globe valves, gate valves, emergency shut-off gate valves, manual and actuated ball valves, safety relief valves, needle valves, check valves, and control valves. They have diverse applications in industries such as solar panel manufacturing, specialty gases, metallurgy, rubber production, food processing, healthcare, automotive, chemicals, transportation, and electronics.

Based on the cryogen, the cryogenic equipment market is segmented into nitrogen, argon, oxygen, liquified natural gas (LNG), hydrogen, and other cryogens. The LNG segment is expected to grow at the highest rate during the forecast period due to increasing investments in LNG infrastructure LNG is a globally traded commodity, with its demand as a cleaner energy source surging worldwide. This has led to the expansion of LNG infrastructure to support international trade and the increasing need for LNG across different regions. LNG’s ease of transport has unlocked previously unprofitable natural gas reserves that were once considered economically unviable due to the high costs associated with pipeline infrastructure. To address the surging LNG demand, countries are making significant investments in LNG storage and regasification infrastructure.

Make an Inquiry: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=735

Based on application, the cryogenic equipment market is segmented into CASU and non-CASU. The non-CASU segment is expected to be the fastest growing market during the forecast period. The market for non-CASU includes the demand for cryogenic equipment across various applications, such as rail & road transport, bulk carrier ships, LNG liquefaction & regasification terminals, and other minor applications. By expanding the ecosystem for air separation technology, the non-cryogenic air separation units (ASUs) can indirectly support the rising demand for cryogenic equipment. Non-cryogenic ASUs work at room temperature and do not directly involve cryogenic processes. Non-cryogenic units have advantages over cryogenic ones for industries and applications that do not need high-purity gases produced by cryogenic ASUs. As industries grow and their need for higher purity gases increases, cryogenic equipment and air separation technologies are likely to become more essential.