The report “Food Robotics Market by Type, Application (Palletizing, Packaging, Repackaging, Pick & Place, Processing), Payload (Low, Medium, Heavy), End-Use Industry, and Region – Trends & Forecast to 2022″, The global food robotics market is estimated at USD 1.37 Billion in 2017 and is projected to reach USD 2.50 Billion by 2022, at a CAGR of 12.80% during the forecast period. The market is driven by factors such as higher demand for packaged foods, increase need to improve productivity, and increase in number of food safety regulations.

Based on type, the market has been segmented into articulated; cylindrical; SCARA; parallel; cartesian; collaborative; and others, including dual arm robots and spherical robots. The articulated segment dominated the market in 2016. Articulated robots have a wide variety of payload capacities. Due to benefits such as increased payload capacity, work envelope, reliability, and speed, articulated robots are used in many different applications; including welding, painting, assembly, packaging, palletizing, depalletizing, machine tending, sealing, gluing, cutting, cleaning, deburring, die casting, grinding, polishing, material handling, case packing, pick & place, pre-machining, and press brake tending.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=205881873

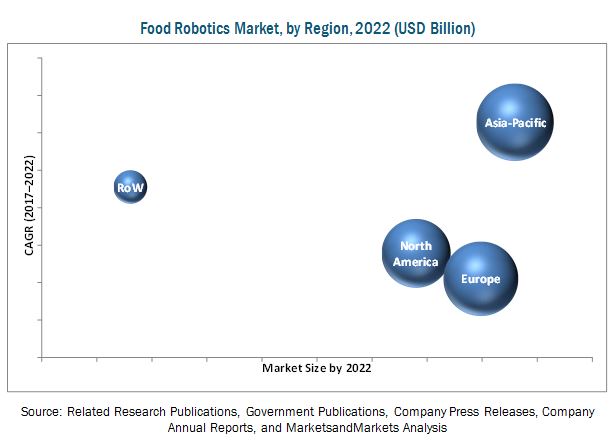

In terms of end-user industry, the beverages segment dominated the market in 2015. The global food robotics market is projected to grow significantly in the Asia-Pacific region, owing to the shift in the food consumption patterns of consumers and increased investments by key food & beverage manufacturers in the region. Food & beverage manufacturers focus on providing the highest quality products, keeping the production cost as low as possible. Also, the rapid turnaround is a critical factor for manufacturers. It is achieved by incorporating advanced automated technologies, which contribute to operational efficiency and increased yield.

In terms of application, the palletizing segment led the market with the largest share. Articulated robots are most widely used in palletizing application. Robotic palletizers help in reducing the operating cost and labor requirements; it also increases the turnaround time and production, alongside reducing the ergonomic issues. These factors have been driving the demand for robotic palletizers in the food & beverage industry.

For the market in payload, the medium payload segment dominated the market in 2016. With the increase in the automation of processes in various industries, manufacturers are offering robots of different payload capacities. This is due to the high usage of medium payload robots in the food & beverage industry, which possess characteristics such as flexibility and dexterity. The low payload capacity market segment is likely to grow at a rapid pace with the high consumption of food products in smaller packs across all regions.

Request for Customization: https://www.marketsandmarkets.com/requestCustomizationNew.asp?id=205881873

The Asia-Pacific region is projected to have the highest CAGR during the forecast period. The countries covered in the Asia-Pacific region is projected to be the fastest-growing market for food robotics due to the demand for ready-to-eat products has increased rapidly among consumers. The packaged food consumption growth increased due to urbanization in the Asia-Pacific region.

The key players in the food robotics market include:

- ABB Group (Switzerland)

- KUKA AG (Germany)

- Mitsubishi Electric Corporation (Japan)

- Kawasaki Heavy Industries Ltd. (Japan)

- Rockwell Automation, Incorporated (U.S.)

- FANUC Corporation (Japan)

- Seiko Epson Corporation (Japan)

- Yaskawa Electric Corporation (Japan)

- Staubli International AG (Switzerland)

- Mayekawa Mfg. Co. Ltd. (Japan)

- Universal Robots A/S (Denmark)

- Bastian Solutions Incorporated (U.S.)