As the digital landscape evolves, the concept of the metaverse is emerging as a transformative force across various sectors. In particular, the industrial metaverse combines advanced technologies such as virtual reality (VR), augmented reality (AR), the Internet of Things (IoT), and artificial intelligence (AI) to create immersive digital environments where industrial processes can be simulated, analyzed, and optimized. This article explores the future of the industrial metaverse, highlighting its potential applications, benefits, and challenges.

Industrial Metaverse Market Outlook

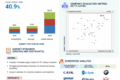

The global industrial metaverse market size is estimated to be USD 28.7 billion in 2024 and is projected to reach USD 228.6 billion by 2029, at a CAGR of 51.5% during the forecast period. The key factors fuelling the growth of this market are the rising adoption of digital twins, advancement in core technologies such as AR, VR, AI, and IoT, rising demand for efficiency and optimization in industrial sector, and addressing skill gaps and workforce challenges through industrial metaverse.

1. Understanding the Industrial Metaverse

The industrial metaverse refers to the interconnected digital ecosystem where businesses can visualize, simulate, and interact with their operations in a virtual space. It encompasses the integration of digital twins—virtual replicas of physical assets, systems, and processes—with immersive technologies to facilitate better decision-making and enhance operational efficiency.

Key Components:

Digital Twins: These are crucial for creating real-time simulations of physical assets, enabling organizations to monitor performance, predict failures, and optimize maintenance schedules.

Immersive Technologies: VR and AR allow users to interact with complex data visualizations and simulations in a more intuitive manner, enhancing training, design, and operational planning.

Data Integration: By leveraging IoT sensors and AI analytics, the industrial metaverse can provide insights derived from vast amounts of data collected from real-world operations.

2. Applications Across Industries

The potential applications of the industrial metaverse are vast and varied, impacting numerous sectors:

Manufacturing

In manufacturing, the industrial metaverse can revolutionize the design and production processes. Engineers can create digital twins of manufacturing lines, allowing them to test configurations and workflows before implementation. AR can facilitate remote assistance, enabling technicians to receive guidance through smart glasses while working on complex machinery.

Supply Chain Management

The metaverse can enhance supply chain visibility by providing real-time tracking and analytics of goods in transit. Digital twins of supply chain networks enable companies to simulate disruptions and develop contingency plans, ultimately leading to more resilient and efficient operations.

Healthcare

In the healthcare sector, the industrial metaverse can support training for medical professionals through realistic simulations of surgical procedures. Moreover, hospitals can create digital twins of their facilities to optimize patient flow and resource allocation, ultimately improving patient care.

Energy and Utilities

For the energy sector, the future of industrial metaverse can be a game-changer in managing complex infrastructures such as power grids and renewable energy sources. Digital twins can simulate energy production and consumption patterns, helping operators optimize resource allocation and predict maintenance needs.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=156427935

3. Benefits of the Industrial Metaverse

The industrial metaverse offers a plethora of benefits that can transform how industries operate:

Enhanced Collaboration

The metaverse enables teams to collaborate in real time, regardless of geographical location. This capability is crucial for organizations with global operations, allowing for more effective communication and project management.

Improved Training and Skills Development

Immersive training environments allow employees to develop skills without the risks associated with real-world scenarios. This is particularly valuable in industries such as manufacturing and healthcare, where hands-on training can be costly and time-consuming.

Cost Reduction

By simulating processes and optimizing operations in a virtual environment, organizations can identify inefficiencies and make data-driven decisions that reduce operational costs. Additionally, predictive maintenance powered by digital twins can help prevent costly downtimes.

Innovation and Design Optimization

The ability to visualize and test new concepts in a virtual environment encourages innovation. Designers and engineers can rapidly prototype and iterate on designs, leading to better products and faster time-to-market.

4. Challenges and Considerations

While the industrial metaverse holds immense potential, several challenges must be addressed:

Data Privacy and Security

As organizations integrate more data into the metaverse, concerns about data privacy and security become paramount. Ensuring robust cybersecurity measures and compliance with data protection regulations is crucial to mitigate risks.

Technological Integration

Integrating various technologies—IoT devices, AI analytics, and immersive experiences—requires significant investment and expertise. Organizations must navigate the complexities of implementing and maintaining these systems to fully leverage the benefits of the industrial metaverse.

Cultural Shift

Adopting the industrial metaverse may require a cultural shift within organizations. Employees may need to adapt to new ways of working, collaborating, and learning, necessitating effective change management strategies and training programs.

5. Looking Ahead: The Roadmap for the Industrial Metaverse

The future of industrial metaverse companies is promising, with several trends expected to shape its development:

Increased Adoption of AI and Automation

As AI technology continues to advance, its integration into the industrial metaverse will enhance data analytics capabilities, enabling organizations to make smarter decisions based on real-time insights.

Standardization and Interoperability

For the industrial metaverse to reach its full potential, standardization and interoperability among various systems and technologies will be essential. Industry-wide collaboration will help develop common frameworks that facilitate seamless integration.

Expansion of Virtual Collaboration Tools

As remote work becomes more prevalent, the demand for virtual collaboration tools within the metaverse will grow. These tools will enable teams to interact, brainstorm, and innovate in immersive digital spaces.

Focus on Sustainability

The industrial metaverse can also play a pivotal role in promoting sustainability. By optimizing resource utilization and reducing waste, organizations can use virtual simulations to support greener practices and achieve their sustainability goals.

The industrial metaverse industry represents a paradigm shift in how industries approach data management, collaboration, and operational efficiency. With its potential to enhance decision-making, foster innovation, and optimize processes, the industrial metaverse is set to revolutionize the future of work. As organizations navigate the challenges of implementation, the focus should remain on harnessing the benefits of this transformative technology to create a more efficient, collaborative, and sustainable industrial landscape. As the metaverse evolves, its impact will undoubtedly be felt across various sectors, driving growth and innovation for years to come.

Major Industrial Metaverse companies include:

- NVIDIA Corporation (US)

- Microsoft (US)

- Siemens (Germany)

- Amazon Web Services, Inc. (US)

- BM (US)

- Meta (US)

- HTC Corporation (Taiwan)

- ABB (Switzerland)

- PTC (US)

- Dassault Systèmes (France)

- GE Vernova (US)

- Intel Corporation (US)

- AVEVA Group Limited (UK)

- Alphabet, Inc. (US),

- Nokia (Finland)