The Core Materials Market consists of lightweight, high-strength materials such as foam, honeycomb, and balsa, primarily used in aerospace, wind energy, automotive, and marine industries for structural reinforcement. The market is experiencing significant growth due to rising demand for durable and energy-efficient materials. The wind energy sector is a key driver, with increasing adoption of composite core materials in turbine blades. Additionally, advancements in automotive and aerospace manufacturing are fueling market expansion. Asia-Pacific is emerging as a dominant region due to rapid industrialization and infrastructure development.

This research report covers major aspects of the industry including drivers, restraints, historical and current trends, regulatory scenarios, and technological advancements. It provides the industry overview with core materials market growth analysis and historical & futuristic cost, revenue, demand and supply data (as applicable). The market for core materials is likely to grow significantly over the next years, rising from USD 1.6 billion in 2023 to USD 3.0 billion by 2028.

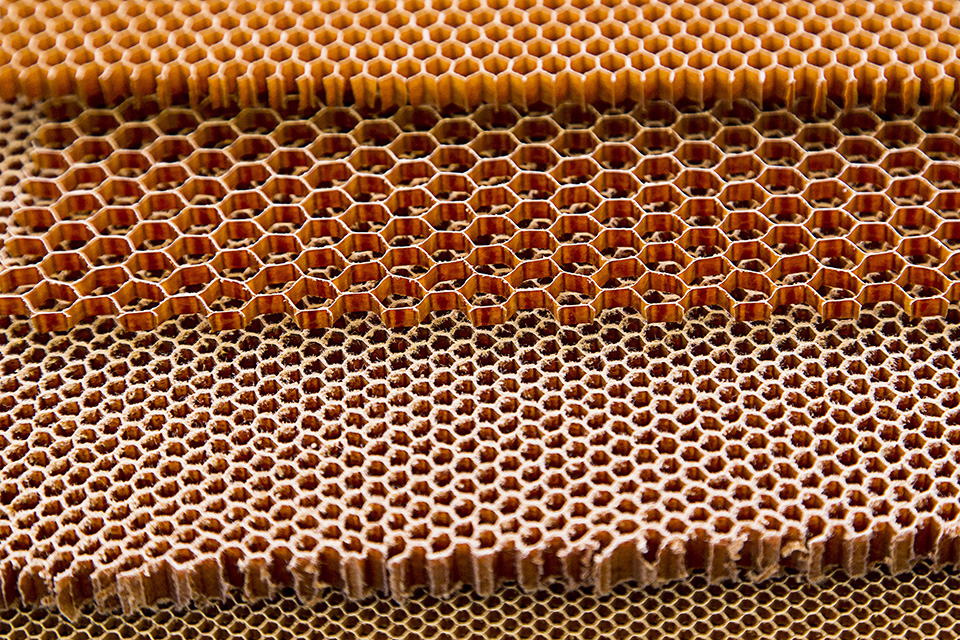

Over the course of the projection period, this growth is anticipated to occur at a compound annual growth rate (CAGR) of 13.5%. Numerous industries, including wind energy, maritime, automotive & transportation, aerospace & military, construction, and industrial areas, use core materials. The core materials business is quickly advancing thanks to strong end-user demand. Materials or substances utilized as the interior or central part of a building or product are known as core materials. These materials frequently serve as insulation, structural support, or in other specialized capacities. Core materials might vary based on the particular use, but some common core materials are foams, honeycomb, and balsa wood.

Request For FREE Sample of Report at https://www.marketsandmarkets.com/requestsampleNew.asp?id=146879627

As the largest end-use industry of core materials, wind energy stands out and stimulates significant demand and innovation in the core materials market. Wind power has become a key component in the transformation to a sustainable energy landscape as a result of the global trend towards renewable energy sources. In order to achieve maximum performance and endurance, wind turbine blades must be constructed with lightweight yet robust frameworks, which is where core materials come into play. The core of contemporary wind turbine blades is made of sandwich composite structures, which frequently make use of materials like foam cores or fiberglass-reinforced composites to maximize energy extraction while enduring the rigors of operation. With government incentives and environmental concerns driving the continued global proliferation of wind farms, there will be an increasing need for sophisticated core materials specifically designed to meet the demands of wind energy applications. The focus on efficiency improvement and technological innovation highlights the critical role that wind energy plays as the primary end-user industry for core materials, influencing the direction of the renewable energy sector and the larger materials business landscape.

Core Materials Market Companies

Prominent players, include 3A Composites (Switzerland), Diab Group (Sweden), Gurit (Switzerland), Hexcel Corporation (US), Armacell S.A. (Luxembourg), Euro-Composites S.A. (Luxembourg), and Changzhou Tiansheng New Materials Co. Ltd. (China). These companies have enhanced their positions in the global core materials market over the past few years by implementing strategies like acquisition, growth agreements and partnerships, and the launch and development of new products.

Download PDF Brochure at https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=146879627

Gurit Holdings AG – In the core materials industry, Gurit Holdings AG is a well-known player, recognized for its creative ideas and steadfast dedication to quality. Gurit is a major worldwide provider of cutting-edge core materials and has a significant influence on a number of industries, including wind energy, construction, aerospace, marine, and automotive. Gurit has a long history that dates back several decades. Throughout that time, it has consistently pushed the limits of composite technology, gaining a reputation for dependability, quality, and innovative research and development. Gurit has been constantly working on its R&D to maintain its market share, for instance in January 2024 Gurit launched Gurit Kerdyn FR+. It is a PET recycled structural foam with Class C – EN13501 test and certification. It offers good compressive strength and stiffness. Additionally, Gurit® Kerdyn™️ FR aligns with the Marine, Civil and Transportation markets’ needs for materials with good Fire, Smoke and Toxicity (FST) properties.

Hexcel Corporation – As one of the market leaders in core materials, Hexcel Corporation is renowned for its innovative contributions and unwavering commitment to the advancement of composite technology. Hexcel is a world leader in advanced composites and is essential to many different industries, such as wind energy, aerospace, automotive, marine, and industrial applications. Hexcel has a long history of pushing the limits of innovation and establishing new benchmarks for sustainability, dependability, and performance. The company’s broad selection of core materials, which includes a variety of foam, honeycomb, and composite solutions, meets the changing needs of clients all over the world. Hexcel is a reliable partner for businesses looking for cutting-edge solutions because of its unrelenting dedication to research and development and unmatched experience in materials science. Hexcel is gaining market share by expansion. For instance, in May 2023 Hexcel Corporation announced the grand opening of a completed expansion at its engineered core operations plant in Morocco to meet the growing demand for lightweight advanced composite materials for the aerospace industry.

Speak to Expert: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=146879627

Lightweight foam core materials are expected to have a significant market share in the global core material market during the forecast period.

Foam is a lightweight and sturdy material; thus, it is the most preferred and economical core material solution in many end use industries. Foams have an excellent strength-to-weight ratio, and this material is easy to process and shape into complex structures. Due to these properties and exemplary mechanical strength and recyclability foam cores are used in various end use industries like wind energy, aerospace, and defense, marine, automotive and transportation, and others. Foam cores are used in sandwich structures to enhance overall structure and mechanisms of composites. Foam cores are manufactured from different thermoplastic and thermoset polymers, including PET, PVC, PU, PEI, SAN, and PMI. Foam core materials can be produced at different densities which range from 2lb/ft3 (30 kg/m3) to 20 lb/ft3 (300 kg/ m3) by changing the blowing agents, the ratio of ingredients in polymers, and adjusting the gas pressure. The foam that holds the maximum share in the foam core material market is the PET foam due to its excellent properties.

The wind energy end use industry is expected to hold the largest share in the global core materials market during the forecast period, in terms of volume and value.

Core materials are used extensively in the wind turbine blades as sandwich panels in the composite structures, hence wind energy is a major end-use industry in the core material market. The wind turbine blades are made by combining core materials and glass- reinforced polyester or epoxy. The core materials that are mainly used in wind energy industry are foam and balsa. Balsa foam core is made from end grain balsa, which is a natural product, this material is used in wind blades because of its excellent mechanical properties, such as high strength-to-weight ratio making them ideal for applications requiring strength and stiffness while being lightweight.

The wind energy capacity is steadily increasing in many geographical regions owing to focus on sustainability and global climate change. Thereby, the demand from wind turbine blade manufacturers has experienced a surge, thereby raising the core material demand from the wind energy end use industry.

Inquire Before Buying: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=146879627

Asia Pacific region to account for the largest market share in the global core materials market during the forecast period.

Countries like India, China, South Korea, and Japan are rapidly developing countries in terms of product innovation and technological advances in many end use industries like wind energy, aerospace & defense, marine, automotive, construction & building, and other industries. The rapidly growing wind energy sector is a significant contributor to the core material market in the Asia Pacific region. These factors are expected to drive the core material market during the coming years in this region.

Detailed TOC of Global Core Materials Market Insights and Forecast to 2028

Introduction

Market Segmentation

Executive Summary

Premium Insights

Market Overview

Core Materials Market By Type

Core Materials Market By End Use

Core Materials Market By Region

Core Materials Market: Company Landscape

SWOT Analysis

Company Profiles

Continued…

Key Questions Addressed by the Report

❓ What are the drivers influencing the growth of the core material market?

❓ Which is the largest and the fastest growing country-level market for core material market?

❓ What are the factors contributing to the final price of core material market?

❓ What is the major restraint in the core material market?

❓ Which type of core material is expected to register highest CAGR?

❓ Who are the major manufacturers?