The industrial agitators market is undergoing a transformative phase, marked by a surge in demand driven by technological advancements and growing industry needs. These critical components, vital for efficient mixing and blending in diverse applications, are seeing innovations that promise to reshape the market landscape. Understanding the current market size, emerging trends, and future prospects is essential for stakeholders aiming to stay competitive and capitalize on new opportunities.

Industrial Agitators Market Size and Dynamics

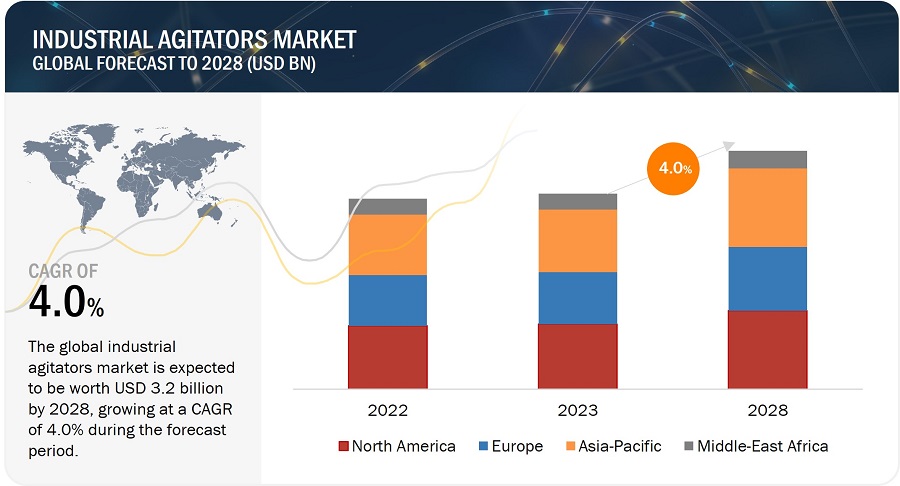

The industrial agitators market is expected to reach USD 3.2 billion by 2028 from USD 2.6 billion in 2023, at a CAGR of 4.0 % during the 2023–2028 period. The major factors driving the market growth of the industrial agitators market include increasing demand for homogeneous mixing, growing need for energy efficient mixing equipment in pharmaceutical, chemical and food & beverage industries, and growing adoption of customized agitators for several applications.

- Technological Innovations: Advances in agitator designs, including the integration of smart technologies, are enhancing performance and versatility. Developments such as automated control systems and real-time monitoring are becoming increasingly prevalent, offering improved process efficiency and data analytics capabilities.

- Growing Industrial Applications: Industries such as chemicals, pharmaceuticals, food and beverages, and wastewater treatment are experiencing a surge in demand for high-performance agitators. This rise is driven by the need for precise mixing, consistency in product quality, and compliance with stringent regulations.

- Expansion in Emerging Markets: Regions like Asia-Pacific and Latin America are witnessing accelerated industrial growth, leading to increased demand for agitators. Investments in infrastructure and manufacturing facilities in these regions are fueling market expansion.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=59649096

Segment Analysis

- By Type: Industrial agitators are categorized into several types, each suited for specific applications:

- Top-entry Agitators: Common in large-scale operations, these agitators are favored for their ability to handle substantial volumes and achieve thorough mixing.

- Side-entry Agitators: Ideal for tanks with limited access, they are used in applications requiring efficient blending without interrupting the process flow.

- Bottom-entry Agitators: Best suited for high-viscosity fluids, these agitators ensure effective mixing from the bottom of the tank.

- By Application: The primary applications of industrial agitators include:

- Chemical Processing: Crucial for mixing chemicals and ensuring uniform reaction conditions in the production of various chemical products.

- Pharmaceuticals: Used for blending active pharmaceutical ingredients and ensuring the consistency of formulations.

- Food and Beverages: Essential for maintaining product quality and consistency in the production of processed foods and beverages.

- Water and Wastewater Treatment: Facilitates the mixing of chemicals and treatment agents, improving the efficiency of purification processes.

- By End-Use Industry:

- Chemicals: The largest segment, driven by the need for advanced mixing solutions in chemical manufacturing.

- Pharmaceuticals: Expanding rapidly due to increasing pharmaceutical production and R&D activities.

- Food & Beverages: Growth fueled by the demand for high-quality and safe food products.

Regional Insights

- North America: Dominates the market due to its established industrial infrastructure and advanced manufacturing capabilities. The presence of leading chemical and pharmaceutical companies supports market growth.

- Europe: Exhibits steady growth with strong industrial bases in countries like Germany, France, and the UK. The region’s emphasis on high-quality production and environmental regulations drives demand.

- Asia-Pacific: Expected to lead in growth rates, driven by rapid industrialization, technological advancements, and increasing manufacturing activities. China and India are key players in this expansion.

- Latin America and Middle East & Africa: Emerging markets with growing industrial sectors are contributing to the steady rise in market demand, driven by infrastructure development and industrial investments.

Challenges and Future Opportunities

The industrial agitators market faces challenges such as high initial costs and the need for regular maintenance. However, these challenges also present opportunities for innovation. Companies are exploring new materials and designs to reduce costs and improve reliability. The integration of digital technologies and IoT in agitator systems is expected to enhance operational efficiency and provide valuable data insights.

The industrial agitators market is poised for significant growth, driven by technological advancements and increasing demand across various industries. Stakeholders must stay informed about market trends and technological developments to seize emerging opportunities and navigate challenges effectively. As industries continue to evolve, the role of industrial agitators in ensuring efficient and high-quality production processes will remain integral to global industrial success.