The world of manufacturing is undergoing a major transformation, and at the heart of this revolution lies Industry 5.0. As the next phase in industrial evolution, Industry 5.0 is reshaping how businesses operate by blending advanced automation, artificial intelligence (AI), robotics, and human expertise. This approach not only focuses on improving production efficiency but also prioritizes sustainability, inclusivity, and a human-centric workforce. In North America, this shift is paving the way for a new era of intelligent, sustainable manufacturing, with the potential to redefine industries from automotive to consumer electronics.

As the market for Industry 5.0 continues to grow, companies are recognizing the benefits of embracing these advanced technologies, offering more opportunities for innovation, productivity, and environmental responsibility. Let’s take a deeper dive into the North American Industry 5.0 market and explore its role in shaping the future of manufacturing.

Understanding Industry 5.0: A New Industrial Revolution

To grasp the importance of Industry 5.0, it’s crucial to understand where it fits in the broader scope of industrial evolution:

Industry 1.0 introduced mechanization with steam-powered machines.

Industry 2.0 ushered in mass production via electricity and assembly lines.

Industry 3.0 brought about automation, computers, and digital technologies.

Industry 4.0 embraced smart factories, interconnected systems, the Internet of Things (IoT), and big data.

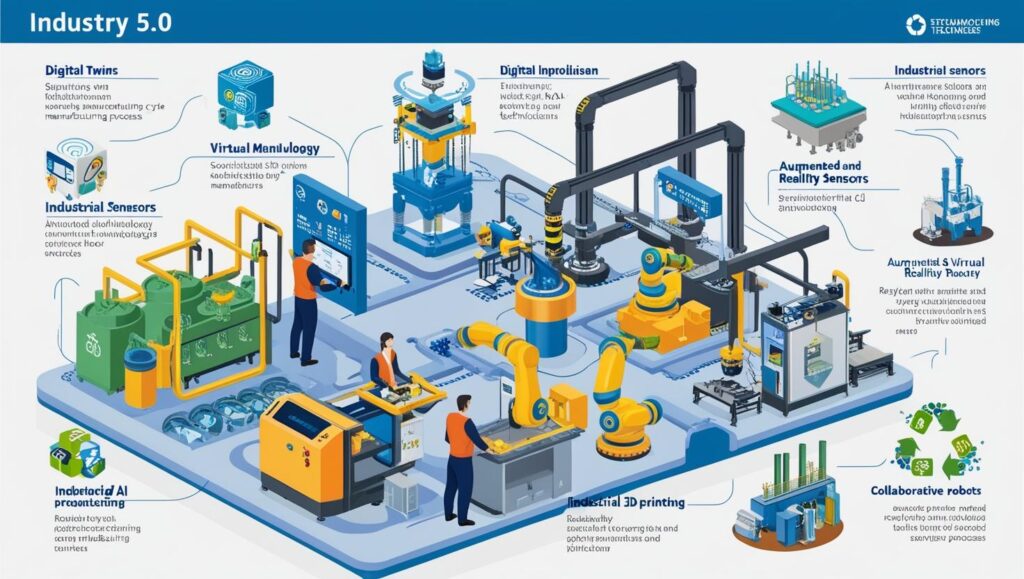

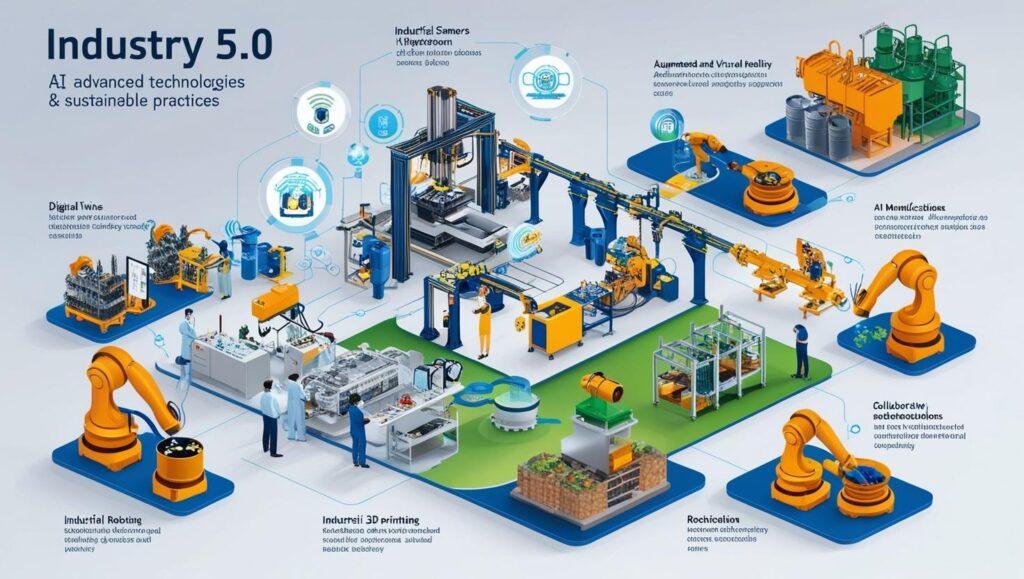

Now, Industry 5.0 takes a leap forward by integrating human intelligence with the automation and efficiency of machines. In Industry 5.0, collaboration between humans and robots becomes central, with the goal of empowering human workers to focus on creative, strategic tasks while leaving repetitive and physically demanding processes to machines. This fusion leads to more personalized production, greater efficiency, and a more inclusive workforce.

Global industry 5.0 Industry

The global industry 5.0 Industry is expected to be valued at USD 65.8 billion in 2024 and is projected to reach USD 255.7 billion by 2029; it is expected to grow at a CAGR of 31.2 % from 2024 to 2029. Several factors are propelling the growth of the Industry 5.0 Industry across diverse industries, including rapid technological advancements in artificial intelligence, robotics, the Internet of Things (IoT), and industrial 3d printing. This evolution responds to the increasing demand for customized products and personalized experiences, fostering a human-centric approach to manufacturing that empowers workers with advanced tools and technologies

Key Drivers of Industry 5.0 Growth in North America

The North American Industry 5.0 market is expanding rapidly, driven by several key factors that emphasize human-centric approaches to manufacturing. Some of these drivers include:

1. Human-Centric Automation

Unlike previous industrial revolutions that focused primarily on replacing human labor with machines, Industry 5.0 promotes human-robot collaboration. With the help of cobots (collaborative robots), human workers are augmented rather than replaced. Cobots work alongside human employees, assisting with tasks that require precision and dexterity, while humans focus on problem-solving and strategic decision-making. This collaboration not only improves productivity but also enhances worker satisfaction and safety.

For example, in industries like automotive manufacturing, cobots assist with tasks such as component assembly, reducing human error and fatigue, while allowing workers to engage in higher-value tasks like design and quality control.

2. Artificial Intelligence and Advanced Analytics

Artificial intelligence (AI) is another key pillar of Industry 5.0. AI-powered systems can analyze vast amounts of data generated by smart factories, identifying patterns and offering insights that lead to optimized production processes. By combining AI with machine learning and predictive analytics, manufacturers can anticipate issues before they arise, reduce downtime, and improve operational efficiency.

In North America, companies are adopting AI technologies to optimize their supply chains, minimize waste, and enhance predictive maintenance. Smart sensors and AI-powered systems can track the condition of machinery in real time, allowing businesses to address potential issues proactively and avoid costly repairs or production delays.

3. Sustainability and Eco-friendly Practices

Sustainability is a core focus of Industry 5.0, especially given the growing need for businesses to address environmental concerns. Industry 5.0 encourages manufacturing processes that not only enhance efficiency but also reduce energy consumption, minimize waste, and lower carbon footprints. This focus on sustainability aligns with North America’s growing commitment to green manufacturing and eco-friendly technologies.

North American companies are implementing sustainable production techniques such as additive manufacturing (3D printing) to minimize material waste and energy consumption. Additionally, Industry 5.0 promotes the use of renewable energy sources and closed-loop systems that reduce the environmental impact of production processes.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=35376359

4. Customization and Personalization

Another major driver of Industry 5.0 is the increasing demand for personalized products. Consumers today are looking for products tailored to their specific needs, and manufacturers must adapt to this growing trend by offering more flexible production capabilities. Industry 5.0 facilitates mass customization, allowing companies to efficiently produce small batches of customized goods without sacrificing cost-effectiveness or efficiency.

This level of personalization is becoming increasingly popular in industries such as consumer electronics, fashion, and healthcare, where customization plays a significant role in customer satisfaction and product differentiation.

5. Smart Supply Chains and Advanced Connectivity

Industry 5.0 is deeply intertwined with advanced connectivity and smart supply chains. Through the use of IoT devices and cloud computing, manufacturers can achieve real-time visibility into their supply chains, helping them make more informed decisions. This level of connectivity fosters greater collaboration among suppliers, manufacturers, and distributors, leading to faster production cycles, fewer bottlenecks, and reduced lead times.

In North America, companies are integrating blockchain technology into their supply chains for greater transparency and traceability, ensuring that products are sourced sustainably and ethically.

Opportunities in the North American Industry 5.0 Market

The growth of the North American Industry 5.0 market presents numerous opportunities for businesses, employees, and consumers alike. Here are some of the major opportunities within this evolving market:

1. Job Creation and Skills Development

While automation may reduce the need for some manual labor, Industry 5.0 is expected to create a significant number of new jobs that require a blend of technical skills and creative problem-solving abilities. Workers in the manufacturing and tech industries will be required to acquire skills in robotics, AI, machine learning, and data analytics to collaborate effectively with advanced systems.

North America’s education and training systems are evolving to equip the workforce with the skills necessary for Industry 5.0. This opens up opportunities for individuals to pursue careers in cutting-edge fields such as robotics engineering, AI programming, and smart manufacturing.

2. New Business Models and Product Innovations

Industry 5.0 encourages businesses to think beyond traditional manufacturing models. With a focus on customization, collaboration, and sustainability, companies can adopt new business models that enable them to create innovative products and deliver more value to their customers.

For instance, manufacturers can offer subscription-based services, where customers receive personalized products on a recurring basis, or they can introduce smart products that are designed to be self-sustaining or self-repairing, reducing the need for constant upgrades and replacements.

3. Enhancing Global Competitiveness

North American companies that embrace Industry 5.0 technologies are well-positioned to remain competitive on the global stage. By integrating AI, automation, and sustainable practices into their operations, they can not only meet the demands of increasingly discerning consumers but also achieve higher productivity, lower costs, and better product quality.

This gives North American manufacturers a distinct advantage in an increasingly globalized marketplace, helping them capture new markets and respond more agilely to changes in consumer preferences and market trends.

The Industry 5.0 market in North America is on the brink of tremendous growth, driven by the need for intelligent, sustainable, and human-centric manufacturing solutions. By integrating advanced technologies such as AI, robotics, and smart supply chains with a focus on sustainability and personalization, North American manufacturers are shaping the future of industrial production.

As businesses continue to adopt Industry 5.0 principles, they will not only improve their operations and product offerings but also contribute to a more sustainable and innovative global economy. The opportunities are vast, and those who embrace this new era of manufacturing will be well-positioned for success in the years to come.

The industry 5.0 companies are includes significant Tier I and II players such as

- ABB, Honeywell International Inc,

- 3D Systems,

- Rockwell Automation,

- Siemens,

- Emerson Electric Co, among others and so on are some of the key players in the industry 5.0 Industry .

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America’s Best Management Consulting Firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. With the widest lens on emerging technologies, we are proficient in co-creating supernormal growth for clients across the globe.

Today, 80% of Fortune 2000 companies rely on MarketsandMarkets, and 90 of the top 100 companies in each sector trust us to accelerate their revenue growth. With a global clientele of over 13,000 organizations, we help businesses thrive in a disruptive ecosystem.

The B2B economy is witnessing the emergence of $25 trillion in new revenue streams that are replacing existing ones within this decade. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the ‘GIVE Growth’ principle, we collaborate with several Forbes Global 2000 B2B companies to keep them future-ready. Our insights and strategies are powered by industry experts, cutting-edge AI, and our Market Intelligence Cloud, KnowledgeStore™, which integrates research and provides ecosystem-wide visibility into revenue shifts.

In addition, MarketsandMarkets SalesIQ enables sales teams to identify high-priority accounts and uncover hidden opportunities, helping them build more pipeline and win more deals with precision.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter , LinkedIn and Facebook .

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103, Delray Beach, FL 33445

USA: +1-888-600-6441

Visit Our Website: https://www.marketsandmarkets.com/