The pressure transmitter market is projected to reach USD 3.84 billion by 2030, expanding from USD 3.21 billion in 2025, at a CAGR of 3.7% during 2025-2030. With rising demand for real-time data analytics and increasing impetus on automation and digitization, the demand for asset performance optimization and predictive maintenance tends to rise.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=937

The transition to cloud-based solutions enhances the scalability and adaptability of pressure transmitter systems, while the rise of Industry 4.0 and smart manufacturing drives the need for interconnected operations and automation. Emphasis on cybersecurity, seamless integration, and real-time data analytics further accelerates advancements in this field. Additionally, the expansion of pressure transmitter applications into emerging sectors like renewable energy and healthcare, along with a growing focus on sustainability and efficiency, continues to shape the evolution of pressure measurement technology.

The liquid fluid type segment in the pressure transmitter market is expected to witness significant growth, with the liquid segment leading in CAGR over the forecast period. Pressure transmitters are essential for accurately measuring and monitoring liquid, gas, and steam pressure across various industries, including oil & gas, chemicals, power generation, and water treatment. Among these, liquid applications dominate due to the widespread need for precise pressure measurement in water management, fuel monitoring, and industrial processing. Advanced pressure transmitter technology enhances operational efficiency by ensuring real-time data accuracy, optimizing process control, and improving safety. In particular, digital advancements in pressure measurement enable seamless data integration across industrial systems, facilitating better decision-making and process automation. By enabling consistent monitoring, pressure transmitters help industries maintain regulatory compliance, reduce downtime, and enhance productivity. The growing demand for smart pressure transmitters with IoT capabilities further strengthens their role in liquid-based applications, making them an indispensable part of modern industrial operations.

The water and wastewater treatment industry is projected to register the fastest CAGR in the pressure transmitter market during the forecast period, driven by the growing need for reliable water management solutions and stricter environmental regulations. Pressure transmitters are essential for monitoring water flow, pressure levels, and treatment efficiency, ensuring smooth operations across water supply networks, sewage systems, and industrial wastewater treatment plants.

With increasing emphasis on sustainability, industries and municipalities are adopting advanced pressure measurement solutions to optimize resource usage and minimize water losses. Modern pressure transmitters equipped with digital capabilities enable real-time monitoring, automation, and remote diagnostics, improving efficiency and reducing maintenance costs. These innovations support proactive decision-making, helping utilities prevent system failures and comply with water quality standards.

Additionally, rising investments in smart water infrastructure and the integration of IoT in utility management are accelerating the adoption of intelligent pressure monitoring solutions. As demand for clean water and efficient wastewater treatment grows, pressure transmitters will play a crucial role in enhancing process reliability and operational efficiency, driving continued market expansion.

The level measurement applicationsegment is expected to hold the largest share in the pressure transmitter market during the forecast period. This growth is driven by the increasing demand for accurate and reliable level monitoring across industries such as oil & gas, chemicals, water & wastewater, and power generation. Pressure transmitters play a vital role in ensuring precise liquid level measurements in storage tanks, processing units, and industrial vessels, helping maintain safety and operational efficiency.With stricter regulations on process safety and environmental compliance, industries are adopting advanced pressure transmitters to enhance monitoring accuracy and prevent overflows, leaks, and equipment failures. Modern pressure transmitters, equipped with digital communication and remote monitoring capabilities, improve process control and reduce maintenance costs by enabling early issue detection.Additionally, the growing integration of automation and smart monitoring systems further boosts the demand for high-performance level measurement solutions. As industries focus on efficiency, safety, and regulatory compliance, pressure transmitters for level measurement will continue to dominate the market, driving overall growth in the measurement application segment.

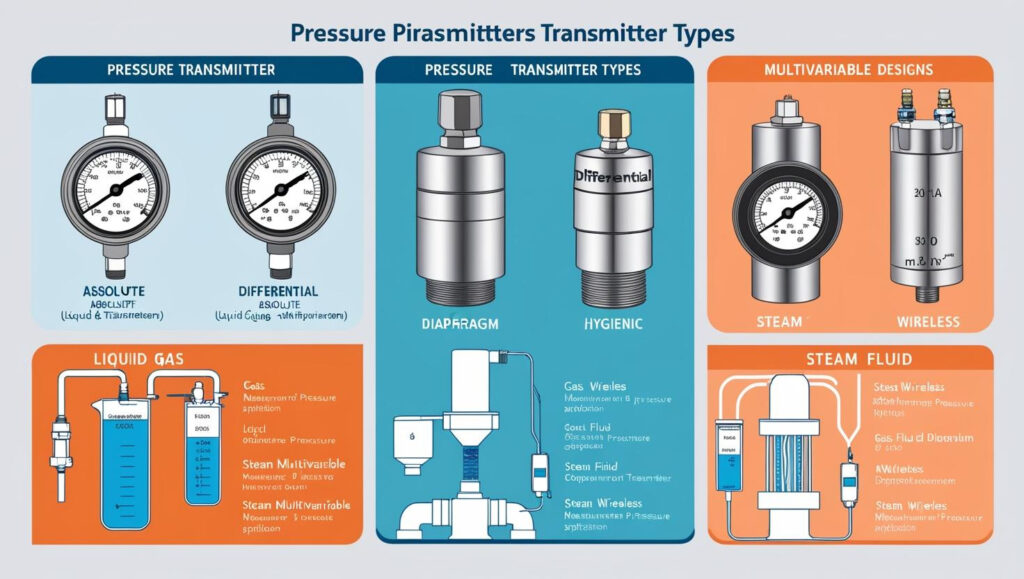

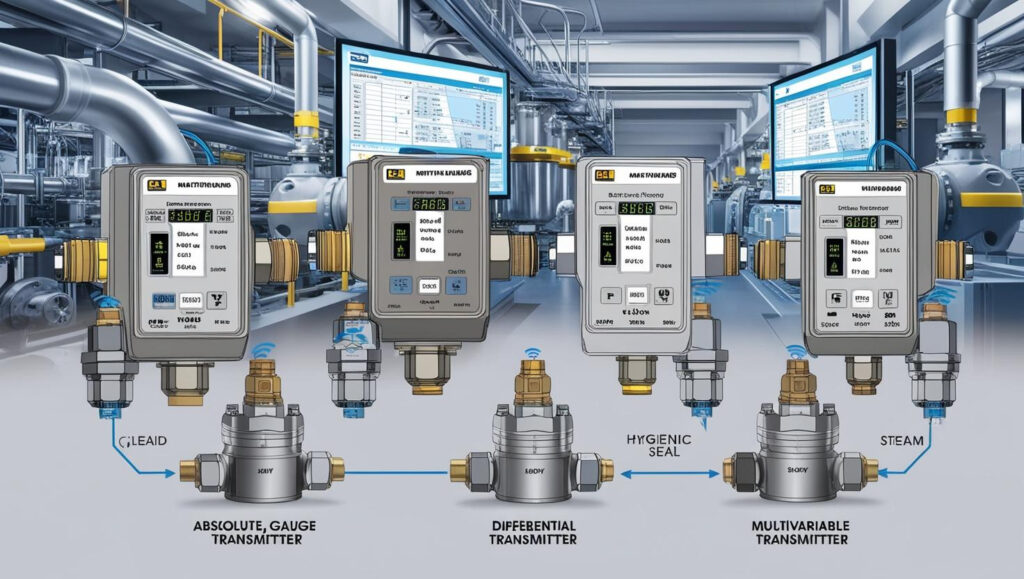

The Multivariable Pressure Transmitter segment is projected to grow at the highest CAGR in the pressure transmitter market due to its ability to measure multiple variables like pressure, temperature, and flow in one device. Other key types include differential, gauge, and absolute pressure transmitters, each serving critical industrial applications. Differential pressure transmitters are vital for flow and level monitoring, while gauge pressure transmitters are used in open systems. Absolute pressure transmitters ensure accuracy in vacuum conditions. The rising adoption of multivariable transmitters helps industries optimize process control, reduce maintenance costs, and improve data accuracy. Their integration with smart automation systems further enhances efficiency and predictive maintenance capabilities.

Asia Pacific is expected to witness the highest growth in the pressure transmitter market due to rapid industrialization, expanding manufacturing activities, and increasing infrastructure development. The region’s strong presence in industries such as oil & gas, chemicals, water treatment, and power generation is driving demand for accurate and reliable pressure measurement solutions. Governments across countries like China, India, Japan, and South Korea are actively promoting automation and smart manufacturing initiatives, further boosting market adoption. Additionally, the rising focus on process efficiency, workplace safety, and environmental monitoring is accelerating the integration of advanced pressure transmitters. The growing investments in industrial IoT and digitalization, along with the presence of major OEMs and sensor manufacturers, are fueling innovation and supporting the region’s market expansion.

Key players in the pressure transmitter market include Emerson Electric Co. (US), ABB (Switzerland), Yokogawa Electric Corporation (Japan), Honeywell International Inc. (US), Endress+Hauser Group Services AG (Switzerland), Schneider Electric (France) and others. These companies have a strong global presence and offer a diverse range of advanced pressure measurement solutions. They continuously focus on innovation, enhancing product performance, and integrating digital technologies to meet evolving industry demands. Additionally, market leaders adopt both organic and inorganic growth strategies, such as partnerships, acquisitions, and new product developments, to strengthen their market position. The industry remains highly competitive, with new entrants emerging and established players expanding their technological capabilities and global footprint.