The robotic welding market is experiencing rapid growth as industries increasingly adopt automation for improved efficiency, precision, and cost savings. With advancements in artificial intelligence (AI), machine learning, and Industry 4.0 technologies, robotic welding systems are becoming smarter and more capable. This article explores the market size, share, and growth trends for robotic welding from 2024 to 2030.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=248099543

Market Size and Growth Projection

The robotic welding market (with peripherals) market is expected to grow from USD 10.38 billion in 2025 to USD 16.87 billion by 2030, growing at a CAGR of 10.2% from 2025 to 2030. The increasing adoption of robotics in manufacturing, particularly in automotive, aerospace, construction, and heavy machinery industries, is driving this growth.

Key factors contributing to the market expansion include:

- The rising demand for automation to enhance productivity.

- The need for high-precision welding in critical industries.

- A growing shortage of skilled welders, pushing industries towards robotic alternatives.

- Government initiatives promoting smart manufacturing and industrial automation.

Market Share by Region

- Asia-Pacific (APAC): Expected to dominate the robotic welding market, with China, Japan, and South Korea leading the way. The region’s strong manufacturing sector, coupled with high investment in automation, is fueling market expansion.

- North America: A key player in the market, driven by the adoption of advanced robotics in the automotive and aerospace industries. The U.S. is the leading contributor in this region.

- Europe: Countries such as Germany, France, and the UK are experiencing steady growth due to the presence of leading automotive manufacturers and stringent quality control standards.

- Rest of the World: Growing industrialization in Latin America and the Middle East is expected to contribute to moderate market growth in these regions.

Industry Growth Analysis

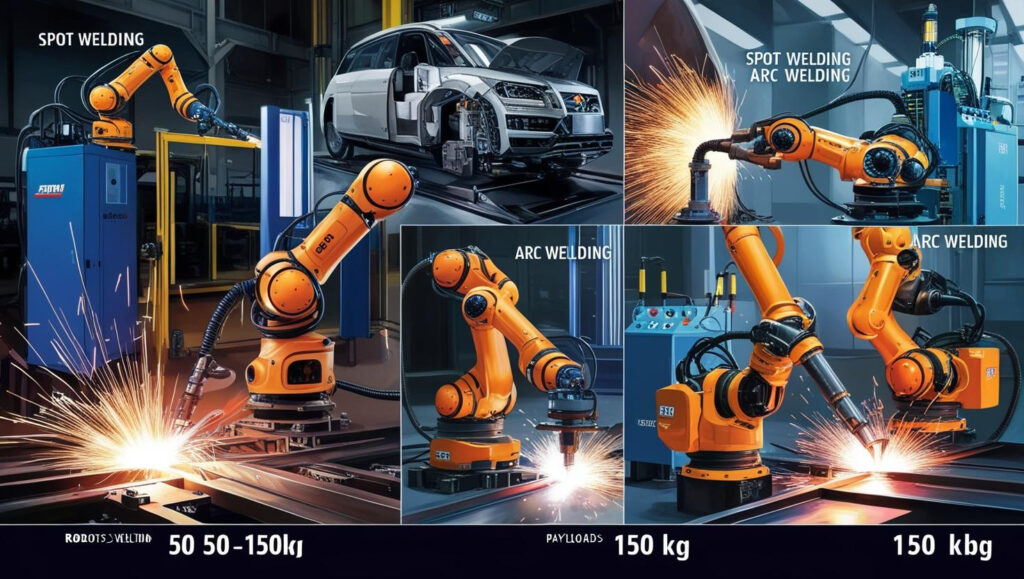

1. Automotive Sector Leading Adoption

The automotive industry remains the largest end-user of robotic welding, accounting for a substantial market share. Automakers are increasingly relying on robotic welding systems to meet high production demands, ensure precision, and maintain uniform weld quality. The transition towards electric vehicles (EVs) is further boosting demand for advanced robotic welding solutions.

2. Growth of Collaborative Robots (Cobots)

Collaborative robots, or cobots, are gaining traction in the robotic welding market. These robots work alongside human operators, enhancing flexibility and safety in welding operations. SMEs are particularly adopting cobots due to their cost-effectiveness and ease of integration.

3. Advancements in AI and Machine Learning

AI-powered welding robots are revolutionizing the industry by enabling real-time monitoring, predictive maintenance, and adaptive welding. Machine learning algorithms allow robotic welders to adjust their welding techniques based on material variations, reducing defects and improving efficiency.

4. Increased Demand for Smart Factories

The push for Industry 4.0 is accelerating the adoption of smart robotic welding solutions. IoT-enabled welding robots provide real-time data analytics, helping industries optimize production and reduce downtime.

Key Market Players

Several major companies are shaping the robotic welding market, including:

- ABB Ltd. – A global leader in robotic automation, offering AI-driven welding solutions.

- FANUC Corporation – Renowned for its high-precision robotic welding systems.

- Yaskawa Electric Corporation – A key player in robotic welding solutions for industrial applications.

- KUKA AG – Specializes in intelligent robotic welding systems for smart manufacturing.

- Panasonic Corporation – Provides integrated robotic welding solutions with IoT and AI capabilities.

The robotic welding market is set for robust growth between 2024 and 2030, driven by advancements in automation, AI, and Industry 4.0 technologies. As industries strive for greater efficiency and precision, the demand for robotic welding systems will continue to rise. With increasing investments and technological innovations, the market is poised to transform global manufacturing in the coming years.