This region is a key smart factory market as it is home to some of the largest multinational corporations operating in this market, including the majority of the leading players. The increased R&D in the field of IoT for new and improved technologies, as well as the increasing demand for improved lifestyle are the two crucial factors driving the market in North America. In addition, rising demand for advanced manufacturing solutions is expected to drive the growth of the smart factory market in North America.

Download PDF Brochure @

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=1227

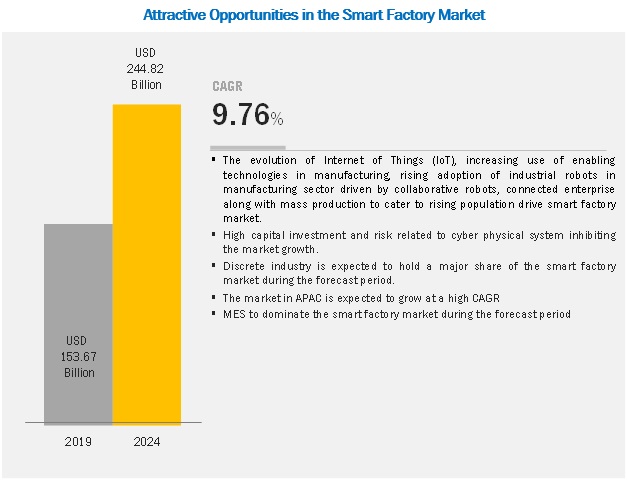

The smart factory market is expected to be valued at USD 153.7 billion in 2019 and to grow at a CAGR of 9.76% during 2019–2024. Smart factory solutions focus on the latest technologies and methods that are currently being adopted to improve the production of various end-user industries. They are used in processes and discrete industries by autonomous systems with the help of different technologies. Factors driving the smart factory market are rising demand for industrial robots in manufacturing sector, increasing adoption of IIoT, importance of energy efficiency, cost reduction and resource optimization, and increasing emphasis on real-time data analysis.

The market for industrial 3D printing is expected to grow at the highest CAGR during the forecast period. Industrial 3D printing comprises scanning and printer software. 3D printing makes the fabrication of intricate shapes easier. This technology alters the tedious process of brazing and welding different components of an object to form a final object. It helps to transform the traditional manufacturing process and naturally drive the smart factory market.

Based on the technologies provided by smart factory, MES is expected to grow at the highest rate from 2019 to 2024. MES applications enable cost savings, improved operations, and high performance of production assets across the supply chain for local manufacturers. Emphasizing on the supply network benefits of an MES is necessary to elevate its priority as a critical vehicle for business processes, cultural change, and educating senior leadership on these benefits.

The smart factory market for the discrete industry is expected to grow at higher rate during the forecast period. In the manufacturing process, discrete manufacturers use automation systems such as distributed control systems (DCS) and programmable logic controllers (PLCs) to operate and control the motors, robots, and conveyors. Automation used in the discrete industry provide several benefits such as consistency of processes, increased throughput, high quality, reduced operation and work-handling time, reduced manual work, and high degree of safety. The discrete industry includes automotive, machine manufacturing, semiconductor & electronics, aerospace & defense, medical devices, and others. The growing demand for smart factory solutions can be attributed to the increase in the need for industrial automation in monitoring, analysis, and controlling the process.

Among different discrete industries, aerospace and defense is expected to grow at the highest rate during the forecast period. The adoption of smart factory solutions in aerospace and defense industry ensures the proper functioning of the entire manufacturing activity in the plant. It offers real-time visibility of the plant floor, and thus helps manufacturers in the aerospace and defense industry to analyse the production process, equipment conditions, and process defect if any. Real-time visibility of the process helps in effective management of the production, further increasing the yield.

APAC is likely to be the fastest-growing market for smart factory from 2019 to 2024. APAC is growing at a high rate with the increasing adoption of industrial automation technologies among industrial sectors, especially across China and India. The governments of APAC countries have encouraged various initiatives of IoT, for example, Smart Nation Singapore Initiative, Made in China 2025, Innovation in Manufacturing 3.0 of South Korea, Productivity 4.0 Program of Taiwan, and Industrial Value Chain Initiative of Japan. The respective governments of these countries encouraged these initiatives to boost the smart factory market.