Steam traps play a crucial role in the efficient functioning of steam systems by discharging condensate and non-condensable gases while retaining steam. As industries continue to evolve with a strong emphasis on energy efficiency, sustainability, and smart technology, steam trap technology is also advancing. The future of steam traps is shaped by innovations in automation, materials, energy efficiency, and predictive maintenance. This article explores the trends, challenges, and developments that will define the next generation of steam traps.

The Current State of Steam Traps

Traditional steam traps have been used for decades in industries such as power generation, food processing, pharmaceuticals, petrochemicals, and HVAC systems. The most common types of steam traps include:

Download PDF Brochure :

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=176735177

- Mechanical Steam Traps: Float and thermostatic traps that operate based on the difference in density between steam and condensate.

- Thermostatic Steam Traps: Operate based on temperature variations between steam and condensate.

- Thermodynamic Steam Traps: Function using the dynamic properties of steam and condensate.

While these steam traps are effective, they have limitations such as failure due to wear and tear, leakage, and inefficiencies in monitoring and maintenance. The future of steam traps focuses on addressing these challenges through automation, IoT integration, advanced materials, and enhanced energy efficiency.

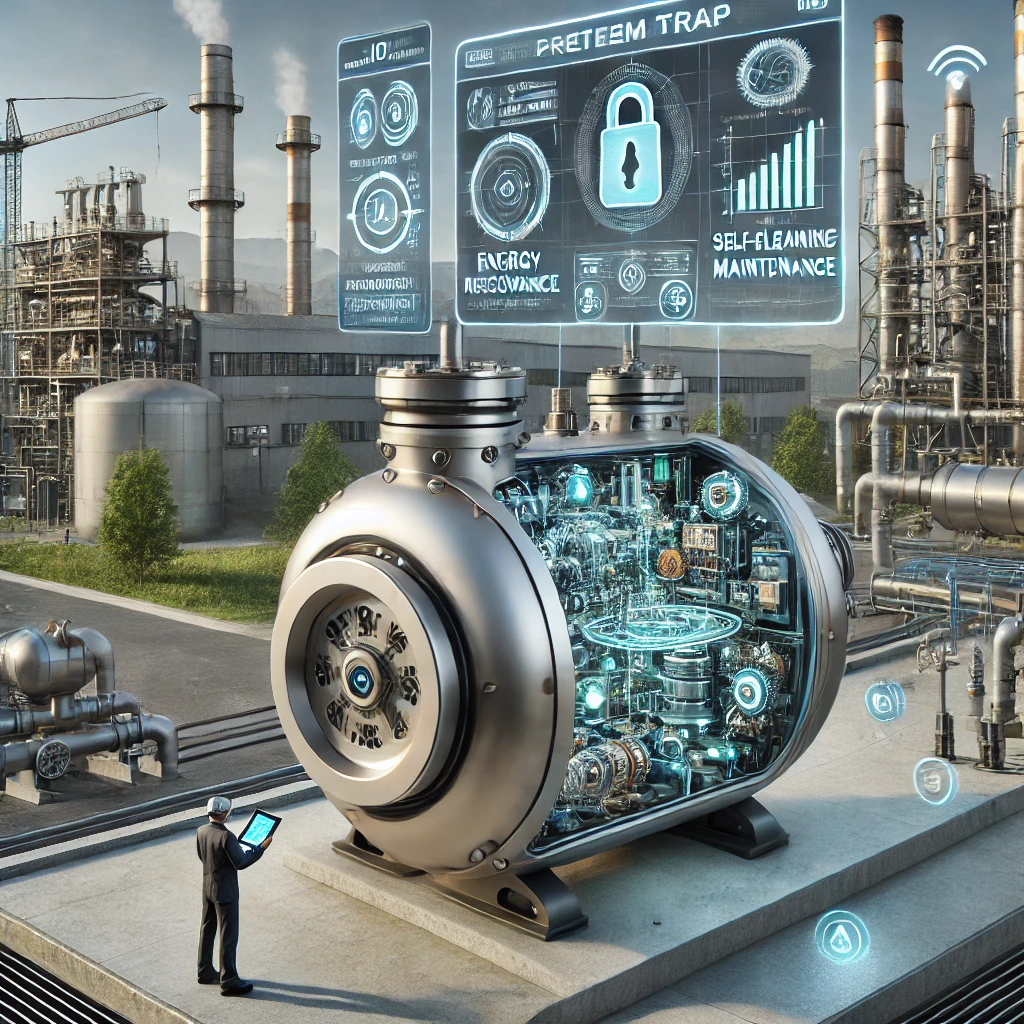

Smart Steam Traps and IoT Integration

The rise of Industry 4.0 has paved the way for smart steam traps that incorporate IoT (Internet of Things) and automation. Smart steam traps are equipped with sensors that monitor pressure, temperature, and condensate levels in real-time. These sensors are connected to a centralized system that allows predictive maintenance and instant alerts in case of failures.

Benefits of Smart Steam Traps

- Real-Time Monitoring: Remote monitoring ensures that steam traps are functioning optimally and reduces manual inspections.

- Predictive Maintenance: Advanced algorithms predict when a steam trap is likely to fail, reducing unplanned downtime.

- Energy Efficiency: By identifying steam leaks and inefficient traps, industries can optimize energy use and reduce costs.

- Integration with AI and Machine Learning: AI-based analytics help in optimizing steam systems and improving efficiency.

- Reduced Carbon Footprint: Efficient steam traps contribute to sustainability efforts by reducing energy wastage.

Advances in Materials and Design

The future of steam traps will also be shaped by innovations in materials and design. Traditional materials such as cast iron and stainless steel are being replaced with more durable and corrosion-resistant materials.

Emerging Materials

- Advanced Alloys: New alloy compositions enhance durability and thermal resistance.

- Ceramic Coatings: Improve longevity by reducing wear and tear from high-pressure steam.

- Graphene-Based Components: Offer superior thermal conductivity and durability, increasing the lifespan of steam traps.

Improved Design Innovations

- Compact and Lightweight Structures: New designs are reducing the weight and footprint of steam traps, making them easier to install and maintain.

- Self-Cleaning Mechanisms: Reduce blockages and ensure longer operational life.

- Hybrid Steam Traps: Combining the best features of mechanical, thermostatic, and thermodynamic traps for improved efficiency.

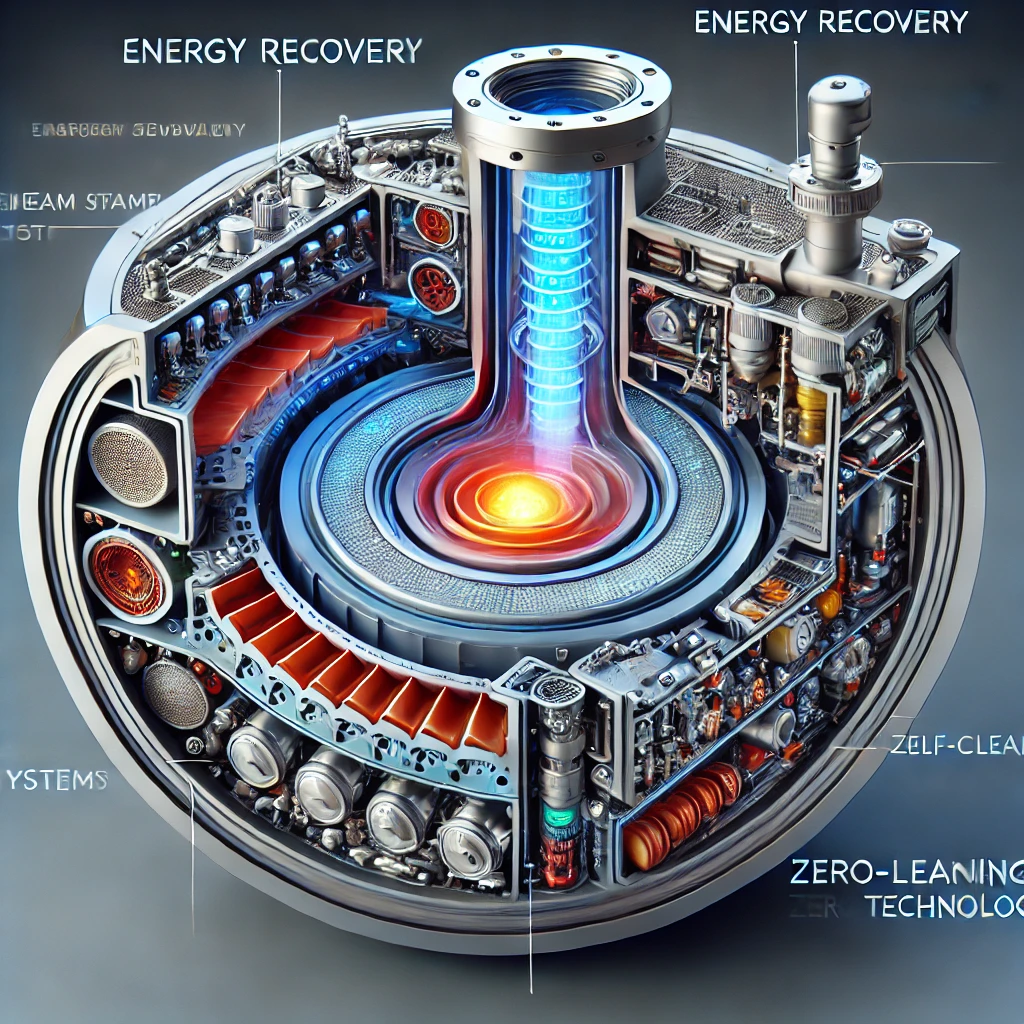

Energy Efficiency and Sustainability

With increasing emphasis on sustainability, the future of steam traps lies in maximizing energy efficiency and reducing carbon emissions. Several initiatives and technological advancements contribute to this goal:

Energy Recovery Systems

Modern steam traps are being designed to recover and reuse energy from condensate. This approach reduces the need for additional energy input, leading to significant cost savings.

Zero-Leakage Steam Traps

Innovations in valve technology and sealing mechanisms are reducing steam losses, ensuring zero leakage, and improving overall system efficiency.

Compliance with Environmental Regulations

Governments and regulatory bodies are imposing stricter energy efficiency standards. Future steam trap designs will align with global sustainability goals, ensuring compliance with environmental laws.

Challenges and Solutions in Steam Trap Technology

Despite the advancements, there are challenges in the adoption and implementation of modern steam trap technologies:

High Initial Investment

Smart steam traps and advanced materials may have higher upfront costs. However, this can be mitigated by long-term savings in energy efficiency and maintenance.

Integration with Legacy Systems

Many industries operate with outdated steam systems that may not be compatible with modern steam traps. Developing retrofit solutions and adaptable technologies will be key to overcoming this challenge.

Skilled Workforce Requirement

The transition to smart steam traps requires a workforce skilled in IoT, data analytics, and automation. Investments in training and skill development will be necessary to ensure smooth adoption.

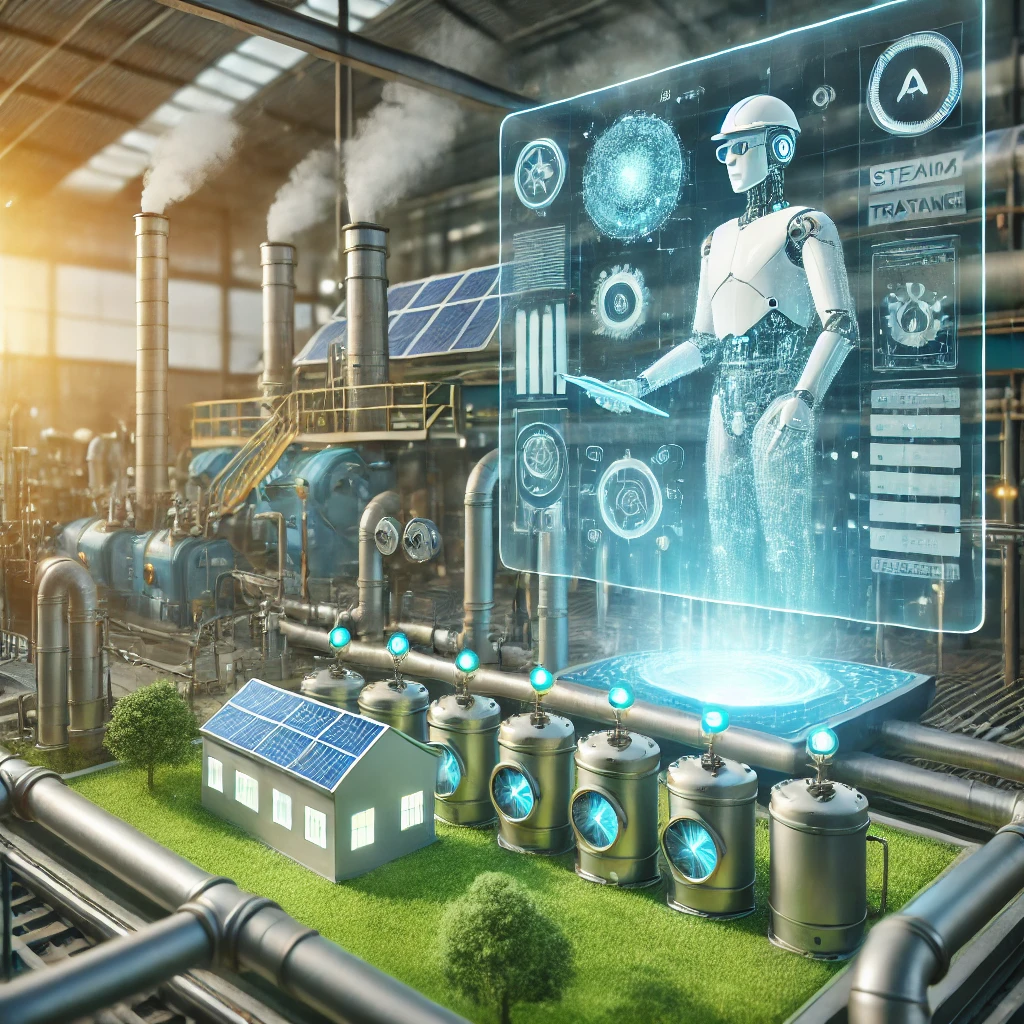

Future Outlook and Industry Adoption

The steam trap industry is poised for significant transformation in the coming years. Several key trends will shape its future:

Adoption of Digital Twin Technology

Digital twins—virtual models of steam systems—will be used to simulate and optimize steam trap performance. This technology will provide deeper insights into system efficiency and maintenance needs.

Expansion in Emerging Markets

Developing countries are rapidly industrializing, increasing the demand for efficient steam systems. The adoption of advanced steam trap technology will accelerate in these regions, driven by energy efficiency needs.

Collaboration with Renewable Energy Systems

Steam traps will play a role in integrating with renewable energy sources such as geothermal and biomass systems, further enhancing sustainability.

The future of steam traps is bright, with significant advancements driven by IoT, AI, energy efficiency, and sustainability. As industries continue to prioritize automation and environmental responsibility, steam trap technology will evolve to meet these demands. By embracing smart steam traps, advanced materials, and predictive maintenance, businesses can enhance efficiency, reduce costs, and contribute to a greener future. The transition to next-generation steam trap solutions is not just an innovation but a necessity for sustainable industrial operations.