The Global recession has affected the manufacturing industry to the larger extent in the last decade. It is now been observed that, in the past few years the manufacturing industry is evolving from its downturn and it is expected to grow prominently in the future. The adoption of industrial controls and factory automation systems will play an important role in the manufacturing process to carry out the better quality and reliable production, reduction in waste, and improved safety.

The Rise of Industrial Controls and Factory Automation Technology:

Manufacturing sector holds the strong share of economy in the regions such as Americas, Europe, and APAC. Due to this, innovators are on the verge of finding new ways to develop and integrate new manufacturing processes for the cost effective and improved production. The technologies such as Supervisory Control and Data Acquisition (SCADA) systems, Distributed Control Systems (DCS), Programmable Logic Controllers (PLC) has given the manufacturing sector the surges of growth.

The arrival of Internet of Things (IoT) and machine to machine (M2M) communication is set to drastically improve the industry’s engineering, production, logistic and life cycle management processes as it allows for a new way of organizing industry production by connecting machines, warehousing systems, and goods. It will enable smart production systems that would control and communicate with each other without any manual intervention.

On the integrated circuits (IC) side, technology such as 3D printing and flexible electronics is gaining momentum. Many R&D activities are being undertaken for the development of flexible sensors, flexible displays, flexible batteries, and other flexible devices which will find wide applications in the industries such as consumer electronics, automobiles, medical and healthcare devices, renewable energy and power, among others.

The Winning Imperatives:

The fully-automated factory is the need of an hour; the decade old machines are now replaced by the intelligent robots. The entire control of the plant is now taken to the central control rooms by the integration of sensors, reliable networks, highly efficient diagnostic software tools.

The major advantages of the automated manufacturing are consistency in the quality of production, reduction in lead time, reduction in waste, and increase in production capacity.

Future of automated manufacturing will be different, with increase in the number of applications and decrease in the production volume the companies will look for a flexible systems which can be customized as per the desired application requirement. The major challenge for the industries offering automation solution will be offering such flexible systems which can be molded as per the requirement of the applications.

The Impact of Globalization on the Manufacturing:

The impact of globalization, trade agreements, and increase in FDI’s had opened the market for the manufacturing sector. The scarcity of skilled and efficient work force has overcome by the entry of billions of people from the developing economy such as China and India. Besides work force, companies are also outsourcing assembly, manufacturing, design and engineering services to the developing nations for the low cost production and increased profits.

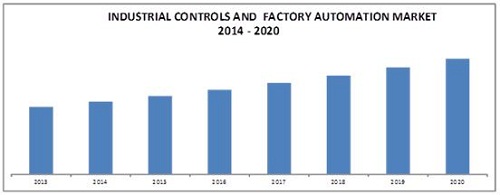

This globalization as eventually increased the market for the industrial controls and the factory automation systems. Currently Americas hold the maximum market share followed by European region. In future, APAC will emerge as the key revenue pocket growing at the highest CAGR.