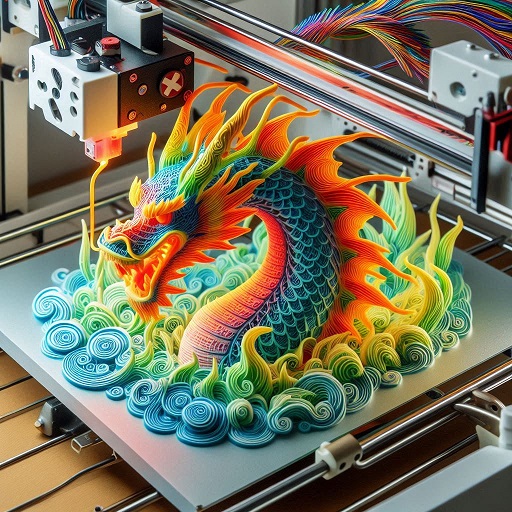

The healthcare industry is in the midst of a transformative revolution, largely fueled by the growing application of 3D printing technology. This innovative approach, which initially started in manufacturing, has opened up new frontiers in medicine, allowing healthcare professionals to provide tailored treatments, optimize surgery outcomes, and enhance the quality of life for patients.

Evolution of 3D Printing in Healthcare

3D printing, also known as additive manufacturing, has come a long way since its inception. Introduced in the 1980s, it initially found applications in industrial settings. However, the early 2000s marked its entry into healthcare. Today, it is reshaping the medical landscape, with advancements allowing for the creation of patient-specific devices and even bioprinted tissues.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=1276

The first notable milestones in healthcare included 3D-printed prosthetics and surgical models, which allowed for precise pre-surgical planning. Over time, the focus has expanded to include more complex applications such as organ printing and customized pharmaceutical products.

Key Benefits of 3D Printing in Healthcare

One of the most significant advantages of 3D printing in medicine is personalization. No two patients are alike, and healthcare solutions must often be adapted to meet individual needs. With 3D printing, custom implants and prosthetics can be produced to fit a patient’s anatomy perfectly, improving both function and comfort.

Moreover, 3D printing drastically reduces both surgery and recovery times. By creating detailed models of organs or bones, surgeons can practice complex procedures beforehand, minimizing errors during actual operations. This precision leads to quicker recovery periods and fewer complications for patients.

3D Printed Prosthetics and Implants

3D printing has revolutionized the field of prosthetics. Traditional prosthetics often require multiple fittings and adjustments, while 3D printing allows for a tailored approach. Custom prosthetics can be produced quickly and affordably, providing improved functionality and aesthetics.

Orthopedic and dental implants have also benefited from this technology. 3D-printed orthopedic devices provide better integration with bones, while dental implants crafted using 3D printing fit patients more precisely, reducing the risk of complications.

Role of 3D Printing in Surgical Planning

For surgeons, 3D printing offers the opportunity to improve precision. Pre-surgical models allow healthcare professionals to visualize complex anatomy and practice procedures before performing them on a patient. This preparation is especially valuable in intricate surgeries, such as brain or heart operations.

Using patient-specific data from CT or MRI scans, 3D models of organs can be printed, enabling a more hands-on approach to surgical planning. This method reduces risks and ensures better outcomes for patients.

Organ and Tissue Printing: The Future of Transplants

Perhaps the most exciting development in 3D printing is bioprinting, which involves the creation of tissues and organs. While still in its infancy, researchers are making strides toward 3D printing fully functional organs. This could solve the global organ shortage crisis, offering hope to patients in need of life-saving transplants.

In addition to organ creation, 3D printing is playing a crucial role in tissue engineering. By printing scaffolds seeded with cells, researchers can create functional tissues for repair or regeneration, paving the way for breakthroughs in regenerative medicine.

Applications of 3D Printing in Pharmaceuticals

The pharmaceutical industry is also seeing the benefits of 3D printing. With this technology, it is possible to print customized pills, allowing for more personalized dosages and drug release profiles. Patients can receive medications tailored specifically to their needs, improving efficacy and reducing side effects.

The advent of 3D-printed pills could also streamline the pharmaceutical supply chain, reducing waste and improving drug accessibility.

Challenges and Limitations of 3D Printing in Healthcare

Despite its advantages, 3D printing in healthcare faces several challenges. One major hurdle is the regulatory approval process. Medical devices and drugs produced via 3D printing must undergo rigorous testing to ensure safety and efficacy, which can slow down innovation.

Technologically, there are still barriers to overcome, including the high cost of equipment and materials, as well as limitations in printing speed and resolution.

Material Innovations in Medical 3D Printing

The materials used in 3D printing are critical to the success and safety of medical devices. Recent advancements have led to the development of biocompatible materials that can integrate seamlessly with human tissue. These innovations include polymers, metals, and ceramics that meet stringent safety standards for medical applications.

For instance, bioactive glass and titanium alloys are now common in orthopedic implants, promoting bone growth and ensuring compatibility with the human body. As material science progresses, more options will become available, expanding the possibilities for 3D printing in healthcare.

3D Printing for Medical Education and Training

One of the most impactful applications of 3D printing is in medical education. Traditional methods of teaching anatomy or surgical techniques often rely on cadavers or computer simulations, which may not provide a realistic experience. However, with 3D-printed anatomical models, medical students and residents can gain a deeper understanding of human anatomy.

3D printed simulators also allow for hands-on training, giving future healthcare professionals the opportunity to practice procedures in a risk-free environment. This immersive learning experience helps build confidence and competence, ultimately leading to better patient outcomes.

Role of 3D Printing in Personalized Healthcare Solutions

Personalized medicine is becoming increasingly important in healthcare, and 3D printing is at the forefront of this movement. By creating tailored implants, prosthetics, and medical devices, healthcare providers can address individual patient needs more effectively.

For example, a custom knee implant designed using a patient’s specific anatomy not only improves comfort but also enhances the functionality of the device. As technology continues to evolve, the potential for even greater customization in healthcare solutions is promising.

Future Trends in 3D Printing in Healthcare

Looking ahead, the future of 3D printing in healthcare is bright. Emerging technologies, such as 4D printing (which allows objects to change shape over time), could further enhance medical applications. Additionally, the integration of artificial intelligence in the design process may lead to more efficient and effective production of medical devices.

Predictions indicate that as costs decrease and accessibility increases, more healthcare providers will adopt 3D printing technologies, making personalized medicine a standard practice rather than an exception.

Globally, efforts are underway to harmonize regulations, allowing for smoother international collaboration in the development of 3D printing technologies in healthcare. By addressing these regulatory challenges, the industry can thrive while maintaining high standards for patient safety.

The role of 3D printing in healthcare cannot be overstated. From creating custom prosthetics to revolutionizing surgical procedures, this technology is transforming the medical field and improving patient outcomes. As innovations continue to emerge and ethical considerations are addressed, the future of 3D printing in healthcare holds immense promise, paving the way for a new era of personalized medicine and advanced medical solutions.

FAQs

Q1: What is 3D printing in healthcare?

A1: 3D printing in healthcare refers to the use of additive manufacturing technology to create customized medical devices, implants, and even tissues or organs tailored to individual patient needs.

Q2: How does 3D printing improve surgical outcomes?

A2: By providing surgeons with detailed, patient-specific models for pre-surgical planning, 3D printing enhances precision and reduces the risk of complications during procedures.

Q3: What materials are used in medical 3D printing?

A3: Common materials include biocompatible polymers, metals like titanium, and ceramics that meet safety standards for medical applications.

Q4: Can 3D printing be used to create organs?

A4: While fully functional organ printing is still in research stages, 3D bioprinting is advancing towards the potential creation of tissues and organs for transplantation.

Q5: What are the ethical concerns surrounding 3D printing in healthcare?

A5: Ethical considerations include patient consent, the ownership of printed organs, and the implications of creating living tissues.

Q6: How is 3D printing shaping the future of personalized medicine?

A6: 3D printing allows for the creation of tailored medical devices and implants that meet individual patient requirements, thereby enhancing the effectiveness of treatments.